Wood Stove

How Does A Wood Stove Work

I’m here to provide insight into the intriguing mechanics of a wood stove.

Ever wondered how this humble appliance magically warms up your home? Well, you’re in luck! In this article, I’ll break down the basics of wood stove design, delve into the combustion process, explore the different types of wood fuel, and discuss the crucial role of airflow in maximizing efficiency.

So grab a cup of tea and get ready to geek out on the science behind cozy warmth.

Key Takeaways

- Wood stoves are made of durable materials like cast iron or steel for heat retention and longevity.

- The combustion process involves different stages, and understanding and controlling these stages is essential for clean and efficient burning.

- Choosing the right type of wood, such as hardwood instead of softwood, and following proper wood burning techniques can increase efficiency.

- Proper airflow control, including air intake and secondary air, is crucial for optimal combustion efficiency and reducing emissions.

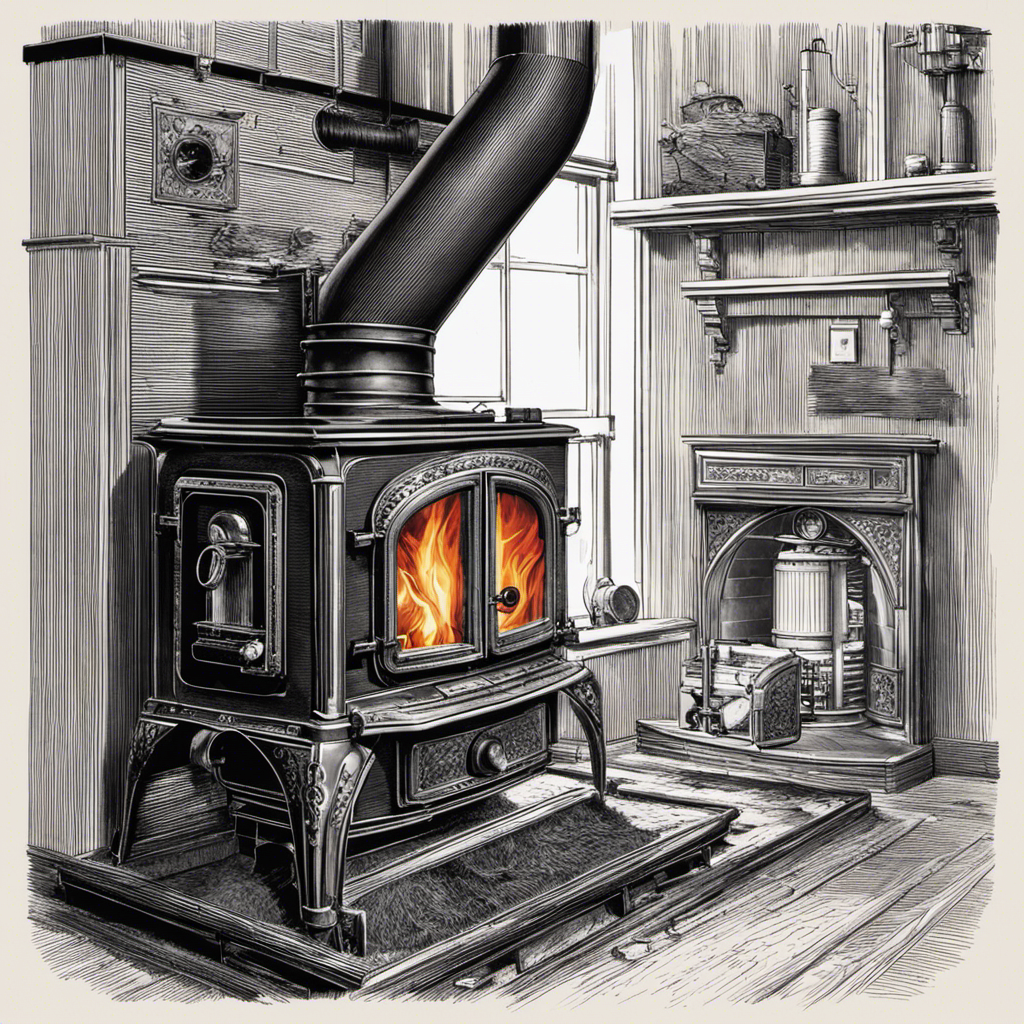

The Basics of Wood Stove Design

I find the basics of wood stove design fascinating. When it comes to wood stove maintenance and installation, understanding the design is crucial.

A wood stove consists of several key components that work together to provide efficient heat. The main structure of the stove is made of cast iron or steel, which allows for durability and heat retention.

The firebox, located inside the stove, is where the wood is burned. It’s designed with refractory bricks or plates to withstand high temperatures.

The baffle system, located above the firebox, helps to direct the flow of gases, ensuring complete combustion and maximum heat transfer.

The flue system, including the chimney, removes the by-products of combustion from the stove. It’s important to ensure proper installation of the flue system to prevent smoke leakage and maintain optimal performance.

Overall, the design of a wood stove is intricate, with each component playing a crucial role in its operation. Understanding the design is essential for efficient wood stove maintenance and installation.

Now, let’s delve into the next section about understanding the combustion process.

Understanding the Combustion Process

The combustion process in a wood stove is fascinating to understand. It involves a combination of chemistry, ignition, and combustion to produce heat and energy. To better grasp this process, let’s take a look at the different stages involved in burning wood.

| Stage | Temperature Range (°C) | Description |

|---|---|---|

| Pre-ignition | Room temperature | This is the stage before the wood is ignited. The wood is dry and contains volatile gases, such as methane and hydrogen. |

| Ignition | 200-300 | At this stage, the wood is heated to a temperature where the volatile gases are released and ignite. This creates a flame and initiates the combustion process. |

| Pyrolysis | 300-500 | During pyrolysis, the wood decomposes due to heat. The volatile gases continue to be released, and solid char is left behind. This char burns slowly and provides additional heat. |

| Combustion | 500-900 | In this stage, the volatile gases and char are burned. The heat released from the combustion process is what generates the majority of the heat output in a wood stove. |

Understanding the chemistry, ignition, and combustion processes involved in a wood stove allows us to appreciate the efficiency and effectiveness of this heating method. By controlling these stages, we can optimize the burning process and ensure a clean and sustainable source of heat.

Fueling a Wood Stove: Types of Wood and Best Practices

When it comes to fueling a wood stove, choosing the right types of wood and following best practices is crucial for optimal efficiency.

Different wood types have varying energy content and burn characteristics, so selecting the appropriate ones can significantly impact the stove’s performance.

Additionally, employing proper wood burning techniques such as seasoning the wood, maintaining adequate airflow, and avoiding overloading the stove can help maximize heat output and minimize emissions.

Wood Types for Efficiency

Using hardwood instead of softwood in a wood stove can increase its efficiency. Hardwood, with its lower moisture content and higher density, burns hotter and longer than softwood. This translates to more heat output and less frequent refueling.

When choosing the right wood for your stove, consider the following:

- Wood moisture: Opt for well-seasoned hardwood with a moisture content of less than 20%. This ensures cleaner combustion and reduces the risk of creosote buildup.

- Wood density: Hardwoods like oak, maple, and birch have higher density than softwoods like pine and spruce. Denser wood provides a higher heat value and burns more efficiently.

- Proper storage: Store your wood in a dry, well-ventilated area to maintain its moisture content and prevent mold or rot.

- Size and splitting: Cut wood into smaller pieces and split them to increase surface area, allowing for faster ignition and better airflow.

- Burning techniques: Follow proper wood burning techniques to maximize efficiency and minimize emissions.

Proper Wood Burning Techniques

I can maximize the efficiency of my wood burning by following proper techniques and guidelines. Wood stove maintenance is crucial to ensure optimal performance. Regularly cleaning the stove, including the chimney and flue, prevents the buildup of creosote, a highly flammable substance. It’s important to use dry, seasoned wood for efficient burning. Wet or green wood produces less heat and more smoke, leading to poor combustion and increased pollution.

Troubleshooting common wood stove problems involves checking for air leaks, which can affect the stove’s efficiency. Sealing any gaps or cracks in the stove’s door or seams can improve performance. Additionally, using a stove thermometer helps maintain the ideal operating temperature.

By following these maintenance and troubleshooting steps, I can ensure my wood stove operates at its highest efficiency, reducing fuel consumption and improving air quality.

Transition: Now that I understand the importance of proper wood burning techniques, it’s essential to explore the role of airflow in wood stove efficiency.

The Role of Airflow in Wood Stove Efficiency

To maximize the efficiency of a wood stove, it’s crucial to understand the role of airflow. Proper airflow control is essential for achieving optimal combustion efficiency, which is the measure of how effectively a wood stove converts fuel into heat. Here are five important factors to consider:

-

Air Intake: The primary air intake controls the amount of oxygen supplied to the fire. Adjusting this intake regulates the combustion process and influences burn rate and heat output.

-

Secondary Air: Secondary air is introduced above the fire to aid in the complete combustion of gases and volatile organic compounds. It helps reduce smoke emissions and increases thermal efficiency.

-

Damper Control: The damper regulates the overall airflow through the stove. By adjusting the damper, you can control the intensity of the fire and the rate at which the wood burns.

-

Airwash System: Many modern wood stoves are equipped with an airwash system, which directs a stream of air across the glass door to keep it clean and clear of soot and creosote deposits.

-

Ash Management: Proper ash management is crucial for maintaining good airflow. Regularly removing ash buildup from the firebox and ash pan ensures optimal combustion efficiency.

Understanding these airflow control measures is vital for maximizing the efficiency of your wood stove and ensuring cleaner and more efficient combustion.

Now, let’s delve into the next section about heat transfer and how a wood stove warms a room.

Heat Transfer: How a Wood Stove Warms a Room

When operating a wood stove, it’s essential to understand how heat is transferred to warm a room effectively.

Heat transfer occurs through three primary mechanisms: convection, radiation, and conduction.

Through convection, warm air circulates throughout the room, while radiation directly emits heat into the surrounding space.

Additionally, heat is transferred through conduction when the stove comes into contact with objects in the room.

Understanding these heat transfer processes is crucial in maximizing the efficiency and effectiveness of a wood stove in warming a room.

Convection: Circulating Warm Air

The warm air inside the wood stove circulates through convection. As the fire burns inside the stove, it heats up the air around it, causing it to rise. This rising hot air creates a cyclical movement, where the cooler air from the room is drawn towards the stove, while the warm air is pushed outwards. This convection process helps in the effective distribution of heat throughout the room.

To further understand the significance of convection in wood stoves, consider the following:

-

Efficiency: Convection ensures that heat is evenly distributed, maximizing the stove’s efficiency.

-

Comfort: The circulating heat creates a more comfortable living environment, eliminating cold spots.

-

Reduced Fuel Consumption: Effective heat distribution means less fuel is needed to maintain a comfortable temperature.

-

Safety: Proper convection helps prevent overheating, reducing the risk of fire hazards.

-

Faster Heat Up: Convection allows for quicker heating of the room, providing warmth in a shorter amount of time.

Overall, the convection process in wood stoves plays a crucial role in efficiently circulating heat and ensuring optimal heat distribution throughout the room.

Radiation: Direct Heat Emission

I can feel the direct heat emitted by the radiation from the wood stove. The process of direct heat emission, also known as thermal radiation, plays a crucial role in how a wood stove works.

When the fire burns inside the stove, the high temperatures cause the stove’s surface to radiate heat in the form of electromagnetic waves. These waves travel through the air and transfer thermal energy to objects and people in their path.

The emitted heat can be felt as a warm sensation on the skin. The effectiveness of the direct heat emission depends on factors such as the temperature of the fire, the size and material of the stove, and the proximity of the objects or individuals to the stove.

Therefore, the wood stove utilizes thermal radiation to directly transfer heat and provide warmth in its surroundings.

Conduction: Transfer Through Contact

Conduction is the process by which heat is transferred through direct contact with objects or surfaces. In the context of a wood stove, conduction plays a crucial role in distributing heat throughout the stove and into the surrounding area. Here are some key points to understand about heat conduction and thermal conductivity:

- Heat conduction occurs when a hot object, such as the walls or components of a wood stove, comes into contact with a cooler object.

- The rate of heat conduction depends on the thermal conductivity of the materials involved. Metals, like cast iron or steel, have high thermal conductivity, allowing them to transfer heat quickly.

- Insulating materials, such as firebricks, are used to reduce heat loss through conduction.

- Proper maintenance of the wood stove, including regular cleaning to remove ash and soot buildup, can help maintain optimal thermal conductivity.

- Ensuring a tight seal between the stove and its surrounding components can also improve heat transfer efficiency.

Understanding the principles of heat conduction and thermal conductivity is essential for effectively using and maintaining a wood stove.

Now let’s explore the next section on maintaining and cleaning your wood stove.

Maintaining and Cleaning Your Wood Stove

To keep my wood stove running efficiently, I make sure to regularly clean and maintain it. One important aspect of maintenance is chimney sweep, which involves removing any built-up creosote. Creosote is a byproduct of burning wood and can accumulate inside the chimney over time. If not cleaned regularly, it can pose a serious fire hazard.

I start by inspecting the chimney to ensure it’s free from any debris or blockages. Then, using a chimney brush, I carefully scrub the inside walls of the chimney to remove any creosote deposits. It’s important to use the right size brush for your chimney to ensure effective cleaning.

Next, I remove the creosote that has fallen into the wood stove. This can be done by scraping the interior walls using a wire brush or a specialized creosote remover. I make sure to wear protective gloves and a face mask to avoid inhaling any harmful particles.

After cleaning, I inspect the chimney cap and spark arrestor to make sure they’re in good condition. I also check the gaskets and seals for any signs of wear or damage, as they can affect the stove’s efficiency.

Regular maintenance and cleaning of my wood stove, including chimney sweep and creosote removal, not only ensures its optimal performance but also helps prevent chimney fires. It’s an essential part of keeping my wood stove safe and efficient.

Safety Tips for Operating a Wood Stove

Operating a wood stove safely requires proper ventilation to prevent the buildup of harmful gases. It’s important to follow safety guidelines to ensure the well-being of your home and family. Here are some essential tips:

-

Clean the chimney regularly: Creosote, a flammable substance, can accumulate in the chimney over time. Regular cleaning prevents chimney fires and allows for proper airflow.

-

Use dry and seasoned firewood: Wet or unseasoned wood can produce more smoke and increase the risk of chimney fires. Dry and seasoned firewood burns more efficiently and reduces the buildup of creosote.

-

Install a carbon monoxide detector: Wood stoves produce carbon monoxide, a colorless and odorless gas that can be deadly if inhaled in high concentrations. Installing a detector can help alert you to any dangerous levels.

-

Keep the area around the wood stove clear: It’s important to maintain a safe distance between the stove and any combustible materials. Clearing the area minimizes the risk of accidental fires.

-

Inspect and maintain the stove regularly: Check the seals, gaskets, and other components of the wood stove regularly to ensure they’re in good condition. Addressing any issues promptly can prevent potential hazards.

Choosing the Right Wood Stove for Your Home

When it comes to selecting the right wood stove for my home, I consider factors such as size, efficiency, and aesthetic appeal. The size of the wood stove is important because it needs to fit properly in the space I have available. Additionally, a smaller stove may not provide enough heat for my needs, while a larger stove may be too much for the room and be wasteful. Efficiency is another key factor to consider. A more efficient wood stove will burn less wood and produce more heat, saving me money in the long run. Lastly, I want a wood stove that will complement the aesthetic of my home. I want it to be visually appealing and fit in with the overall design of the space.

To help make the decision-making process easier, I have created a table below that compares different wood stoves based on their size, efficiency, and aesthetic appeal:

| Wood Stove | Size (in square feet) | Efficiency (%) | Aesthetic Appeal |

|---|---|---|---|

| Stove A | 1000 | 80 | Modern |

| Stove B | 1500 | 85 | Rustic |

| Stove C | 1200 | 90 | Traditional |

| Stove D | 800 | 95 | Contemporary |

| Stove E | 1300 | 75 | Vintage |

Frequently Asked Questions

Are Wood Stoves Safe to Use in Small Spaces Like Apartments or Mobile Homes?

Yes, wood stoves can be used safely in small spaces like apartments or mobile homes. Proper wood stove ventilation is crucial to ensure the safety of the occupants.

It’s important to follow safety precautions such as installing carbon monoxide detectors, keeping flammable materials away, and regularly cleaning and maintaining the stove.

Additionally, using a smaller, well-insulated wood stove specifically designed for small spaces can further enhance safety.

Can I Use Wood Pellets as Fuel in a Wood Stove?

Using wood pellets in a wood stove has both pros and cons.

Wood pellets are a convenient and efficient fuel source. They produce a high heat output and burn cleanly, with minimal smoke and ash.

However, they can be more expensive than traditional firewood and may require a special pellet stove or a conversion kit for your wood stove.

It’s important to consider your specific needs and preferences before deciding to use wood pellets as fuel in a wood stove.

How Often Should I Clean the Chimney When Using a Wood Stove?

When it comes to wood stove maintenance, one important aspect is the frequency of chimney cleaning. It’s crucial to clean the chimney regularly to ensure proper ventilation and prevent potential hazards.

The recommended frequency for chimney cleaning varies depending on factors such as usage and the type of wood being burned. However, as a general guideline, it’s advisable to have the chimney inspected and cleaned at least once a year by a professional chimney sweep to maintain optimal performance and safety.

Is It Possible to Overheat a Room With a Wood Stove?

Yes, it’s possible to overheat a room with a wood stove if proper ventilation isn’t maintained.

Wood stoves produce a significant amount of heat, and if the room isn’t adequately ventilated, the heat can build up quickly.

This can lead to uncomfortable conditions and even pose a risk of fire.

It’s important to ensure that the room has proper airflow and that the wood stove is used responsibly to prevent overheating and maintain a safe environment.

What Are the Environmental Impacts of Using a Wood Stove for Heating?

When using a wood stove for heating, it’s important to consider the environmental impacts. Wood burning can release harmful pollutants into the air, contributing to air pollution. Additionally, the demand for wood as fuel can lead to deforestation and habitat loss.

To mitigate these impacts, it’s crucial to use a wood stove that’s certified as low-emission and to source wood from sustainable, well-managed forests. Regular maintenance and proper operation of the stove can also help reduce emissions.

Conclusion

In conclusion, wood stoves are an efficient and environmentally-friendly way to heat your home. Did you know that a well-maintained wood stove can have an efficiency rating of up to 80%? This means that 80% of the heat generated from burning wood is effectively transferred into your living space.

By choosing the right wood stove and following best practices, you can enjoy a cozy and warm home while reducing your carbon footprint. Stay safe and enjoy the benefits of a wood stove!

Wood Stove

How Long Does It Take Wood To Ignite Aftee Being Put In A Wood Stove

I must admit, the wait for wood to catch fire in a wood stove can seem never-ending. However, do not worry, as in this article, I will share some strategies and tips to speed up the process.

From understanding the temperature and moisture content of the wood to choosing the right type and preparing it efficiently, we’ll explore all the factors that affect wood ignition time.

So let’s dive in and get that fire blazing in no time!

Key Takeaways

- Weather conditions and moisture content of the wood can affect the ignition time.

- Properly seasoned wood with around 20% moisture content ignites more easily.

- Smaller wood logs and softer woods tend to ignite faster than larger and harder woods.

- Proper wood storage and preparation, such as keeping it off the ground, using fire starters, and maintaining airflow, can help ensure faster ignition in a wood stove.

Factors Affecting Wood Ignition Time

I’m curious about the factors that can affect the time it takes for wood to ignite in a wood stove.

One of the key factors is the weather conditions. Cold and damp weather can make it harder for the wood to catch fire, as moisture content in the wood can be high. It’s important to ensure that the wood is properly seasoned and has a moisture content of around 20% for optimal ignition.

Another factor to consider is the size of the wood logs. Smaller logs tend to ignite more quickly as they’ve a larger surface area exposed to the heat source.

Additionally, the type of wood being used can also affect ignition time, with softer woods igniting faster than harder woods.

Temperature and Moisture Content of Wood

The optimal moisture content for wood is around 20%, which ensures efficient ignition in a wood stove. The wood ignition process is influenced by various factors, and the moisture content plays a critical role in determining how quickly the wood will ignite.

When wood is too wet, it requires more energy to burn off the excess moisture before it can reach its ignition point. On the other hand, if the wood is too dry, it may ignite too quickly and burn too rapidly, leading to inefficient combustion and wasted energy.

Therefore, it’s essential to properly store wood to maintain its moisture content within the optimal range. Proper wood storage involves keeping the wood off the ground, covering it to protect it from rain or snow, and allowing for proper airflow to prevent excessive moisture buildup.

Type of Wood and Its Density

I prefer using hardwoods like oak or maple due to their density and their ability to burn longer and provide more heat. When it comes to wood species selection, it’s important to consider the impact of wood moisture content. Here are three key points to keep in mind:

-

Moisture content affects combustion efficiency: Wet wood contains a higher moisture content, which leads to incomplete combustion and the production of more smoke and pollutants. Dry hardwoods, on the other hand, burn more efficiently and produce less smoke.

-

Heat output is influenced by wood density: Hardwoods have a higher density compared to softwoods, resulting in a higher heat output. This means that hardwoods like oak and maple can provide more warmth and keep your space cozy for a longer period of time.

-

Longer burn time with hardwoods: Due to their density, hardwoods burn at a slower rate, allowing for a longer burn time per log. This means less frequent refueling and a more consistent heat source.

Preparing Wood for Efficient Ignition

To ensure efficient ignition, I always make sure to properly split and dry my firewood. Proper wood storage is essential for achieving this. It’s important to store the firewood in a well-ventilated area, off the ground and protected from moisture. This allows the wood to dry properly and reduces the risk of it being damp or rotting.

When it comes to igniting the wood in a wood stove, using fire starters or kindling can greatly speed up the process. These small pieces of flammable material help create a hot and sustained flame, which in turn ignites the larger pieces of wood.

By incorporating these techniques, you can ensure a faster and more efficient ignition in your wood stove.

Now, let’s move on to some tips for faster wood ignition in a wood stove.

Tips for Faster Wood Ignition in a Wood Stove

Using kindling and ensuring proper airflow are key to achieving faster wood ignition in a wood stove. When it comes to stubborn wood that’s difficult to ignite, there are several ignition techniques that can be employed:

-

Preparation: Properly seasoned wood with a moisture content below 20% is essential for efficient ignition. This ensures that the wood is dry enough to catch fire quickly.

-

Kindling: Creating a bed of small, dry kindling underneath the larger logs helps to ignite the fire faster. Kindling acts as a fuel source that ignites easily and produces enough heat to catch the larger logs on fire.

-

Airflow: Adequate airflow is crucial for wood ignition. By opening the damper or adjusting the air vents, you can ensure that enough oxygen is getting to the fire, promoting faster ignition.

While some may consider using accelerants to speed up wood ignition, it’s important to note that this can be dangerous and may result in uncontrollable fires or the release of harmful chemicals. It’s recommended to rely on proper ignition techniques and patience for a safe and efficient wood ignition process.

Frequently Asked Questions

Can I Use Treated Wood in My Wood Stove?

Using pressure treated wood in a wood stove is not recommended due to the chemicals it releases when burned. It is safer to use untreated wood or other alternatives for faster ignition.

What Is the Best Type of Wood to Use for Faster Ignition in a Wood Stove?

Fast burning woods like pine or fir can ignite in a wood stove within minutes. To ensure efficient wood stove usage, it’s important to choose dry, seasoned firewood and properly maintain the stove.

Are There Any Safety Precautions I Should Take When Igniting Wood in a Wood Stove?

When igniting wood in a wood stove, it is important to take safety precautions. Keep a fire extinguisher nearby and ensure proper ventilation. Additionally, the moisture content of the wood can affect its ignition time.

Can I Use Wood Chips or Sawdust for Ignition in a Wood Stove?

I can use wood chips or sawdust for ignition in a wood stove. They are effective fire starters for faster ignition. The small size and high surface area make them ignite quickly, reducing the time needed for the wood to catch fire.

How Does the Size of the Wood Affect Its Ignition Time in a Wood Stove?

Moisture content significantly affects wood ignition in a wood stove. Smaller pieces of wood ignite faster due to increased surface area. However, larger pieces provide longer burn times. Consider the advantages and disadvantages of each for efficient use in a wood stove.

Conclusion

After careful analysis of the factors affecting wood ignition time, it’s safe to say that wood doesn’t ignite instantly in a wood stove. Contrary to popular belief, wood requires time to reach its ignition point, which is influenced by factors such as temperature, moisture content, and wood density.

To expedite the process, it’s crucial to choose the right type of wood and ensure it’s properly prepared. So, if you were expecting an immediate burst of flames, you might’ve to wait a little longer.

Logan’s affair with adventure began in childhood. He hailed from a small town where vast forests bordered one side and endless shores stretched on the other. His days were spent exploring uncharted woods, climbing tall trees, or listening to the tales of old sailors. This early immersion in a world brimming with stories and mysteries became the foundation of his passion for writing.

Wood Stove

Why Does Your Wood Stove Smoke

Dealing with the smoke from your wood stove can be a real nuisance. But don’t worry, I’m here to provide some tips on how to manage it.

Understanding the root causes of this predicament is crucial. Insufficient airflow, improper wood selection, damaged chimney, inadequate maintenance, and incorrect installation are the major culprits.

Let’s delve into each of these factors to uncover the secrets behind why your wood stove may be producing that bothersome smoke.

Key Takeaways

- Blocked vents disrupt combustion process and lead to incomplete burning and smoke generation.

- Burning wet or high-moisture wood results in inefficient burning and increased creosote buildup.

- Cracked or deteriorating chimney can cause leaks and smoke entry.

- Inadequate stove maintenance, including dirty burners and clogged flue, can lead to smoke issues.

Insufficient Airflow

I’m having trouble with my wood stove smoking because there’s not enough airflow. A common cause of insufficient airflow is blocked vents. When the vents are blocked, the combustion process is disrupted, leading to incomplete burning of the wood and the generation of smoke.

To ensure efficient combustion and minimize smoke, it’s crucial to maintain clear and unobstructed vents. Blocked vents can result from a buildup of creosote or debris, so regular cleaning is essential.

Additionally, proper placement of the stove is crucial to ensure adequate airflow. Make sure that the stove is positioned away from any obstructions, such as furniture or curtains, that might impede the flow of air.

Improper Wood Selection

To prevent excessive smoke and poor combustion, it’s important to avoid burning wet wood or wood with high moisture content, as it can result in inefficient burning and increased creosote buildup. When burning seasoned firewood, which has a moisture content of around 20% or less, the wood burns more efficiently, producing less smoke and providing more heat output. Seasoned firewood has been properly dried for at least six months, allowing the moisture content to decrease significantly. This ensures that the wood burns cleanly and effectively in your wood stove. However, if you burn wood with high moisture content, it will create more smoke and reduce the overall efficiency of your stove. This can also lead to a higher risk of creosote buildup in your chimney, which can be dangerous and increase the chance of a chimney fire. Therefore, it’s crucial to always use dry, seasoned firewood to prevent excessive smoke and maintain proper combustion in your wood stove.

Now, let’s discuss another potential reason for excessive smoke: a damaged or leaky chimney.

Damaged or Leaky Chimney

A damaged or leaky chimney can cause smoke to enter your home, which can be hazardous to your health and safety. It’s important to address any issues with your chimney promptly to ensure the proper functioning of your wood stove.

Here are three signs of a damaged chimney that you should be aware of:

-

Cracked or crumbling mortar: If you notice any cracks or crumbling in the mortar joints of your chimney, it could indicate water damage or structural issues. This can lead to leaks and smoke entering your home.

-

Rusty or deteriorating chimney cap: The chimney cap plays a crucial role in keeping out rain, snow, debris, and animals. If it’s rusty or deteriorating, it may not be able to perform its function effectively, allowing smoke to escape into your living space.

-

Smoke stains or odors: If you notice smoke stains on the walls or ceilings near your chimney or detect a persistent smoky odor in your home, it could be a sign of a leaky chimney. This should be addressed promptly to prevent further damage and potential health risks.

When faced with a damaged chimney, there are various repair options available, such as chimney relining, chimney crown repair, and chimney flashing repair. It’s important to consult with a professional chimney technician to determine the best course of action for your specific situation.

Inadequate Stove Maintenance

One of the main causes of smoke in your home can be the result of inadequate stove maintenance. A dirty stove and a clogged flue are two common culprits that can lead to smoke issues. When the stove isn’t properly cleaned, a buildup of soot and debris can occur on the burners, causing incomplete combustion and the production of smoke.

Additionally, a clogged flue prevents the proper ventilation of smoke, leading to its accumulation inside your home. Regular cleaning and maintenance of your stove, including cleaning the burners and ensuring the flue is clear, is crucial in preventing smoke issues.

It’s recommended to schedule annual professional maintenance to ensure your stove is in optimal condition and to avoid the inconvenience and potential health hazards associated with smoke in your home.

Incorrect Stove Installation

I regret not hiring a professional for my stove installation, as it has caused numerous issues and potential hazards. When it comes to installing a wood stove, proper positioning and sizing are crucial factors that shouldn’t be taken lightly.

Here are three key reasons why improper stove positioning and incorrect flue size can lead to problems:

-

Inadequate clearance: Placing the stove too close to combustible materials can increase the risk of fire. It’s essential to follow the manufacturer’s guidelines for proper clearances to ensure the safe operation of the stove.

-

Inefficient heating: Incorrect positioning can hinder the stove’s ability to distribute heat effectively throughout the room. This can result in uneven temperatures and wasted energy, leading to discomfort and higher heating costs.

-

Insufficient draft: Using an incorrect flue size can impede the stove’s ability to expel smoke and gases properly. This can lead to backdrafting, where smoke enters the room instead of being directed outside. Aside from the health hazards, backdrafting can damage the stove and cause indoor air quality issues.

To avoid these problems, it’s essential to consult a professional for the proper installation of your wood stove. They’ll ensure that the stove is positioned correctly and the flue size is appropriate for efficient and safe operation.

Frequently Asked Questions

Can Smoking Occur if There Is Sufficient Airflow in the Wood Stove?

Yes, smoking can still occur in a wood stove even with sufficient airflow. Factors like improper wood placement, damp or unseasoned wood, or a clogged chimney can all contribute to smoking issues. Proper troubleshooting can resolve these problems and improve wood stove performance.

What Are Some Common Wood Types That Should Be Avoided to Prevent Smoking in a Wood Stove?

To prevent smoking in a wood stove, it is important to avoid using wood types like pine, as they contain high levels of resin. Additionally, properly seasoning firewood is crucial to reduce smoke production.

How Can I Identify if My Chimney Is Damaged or Leaking?

To identify chimney damage or leaks, conduct a thorough chimney inspection. Look for cracks, loose bricks, or crumbling mortar. Additionally, consider installing a smoke detector near the stove to quickly detect any smoke issues.

Besides Regular Cleaning, What Other Maintenance Practices Can Help Prevent Smoking in a Wood Stove?

Other maintenance practices, such as ensuring proper airflow and avoiding certain wood types, can help prevent smoking in a wood stove. Identifying chimney damage or leaks and checking for correct stove installation are also crucial.

What Are Some Signs of Incorrect Stove Installation That May Lead to Smoking?

Installing a wood stove improperly can lead to frustrating smoke issues. One key sign is if the chimney height is too short. Another is using unseasoned wood, which can cause excessive smoke.

What Are Some Wood Stove Brands That Have Smoke-Reducing Features?

Looking for the best wood stove brands with smoke-reducing features? Look no further. With increasing concerns about air pollution, several brands are innovating their wood stoves to minimize smoke emissions. Some notable options include Vermont Castings, Jøtul, and Blaze King. These brands prioritize efficiency and clean burning, ensuring you can enjoy the warmth of a wood stove while minimizing environmental impact.

Conclusion

In conclusion, when your wood stove smokes, it’s often due to factors such as:

- Insufficient airflow

- Improper wood selection

- A damaged or leaky chimney

- Inadequate stove maintenance

- Incorrect installation

To prevent this, you should:

- Ensure proper ventilation

- Use seasoned and dry wood

- Inspect and repair your chimney regularly

- Maintain your stove diligently

- Ensure professional installation

By addressing these issues, you can enjoy a smoke-free and efficient wood stove experience, creating a cozy and inviting atmosphere in your home.

Logan’s affair with adventure began in childhood. He hailed from a small town where vast forests bordered one side and endless shores stretched on the other. His days were spent exploring uncharted woods, climbing tall trees, or listening to the tales of old sailors. This early immersion in a world brimming with stories and mysteries became the foundation of his passion for writing.

Wood Stove

How To Build A Wood Stove From A Jerry Can

I have always been fascinated by the concept of transforming ordinary objects into useful tools.

So when I came across an old jerry can in my garage, I knew I had the perfect opportunity to create my own wood stove.

In this article, I’ll guide you through the process of transforming a jerry can into a functional and efficient wood stove, complete with ventilation, legs, and a base.

Get ready to unleash your inner DIY enthusiast and start enjoying the warmth of your homemade wood stove.

Key Takeaways

- Consider the capacity and dimensions of the jerry can

- Compare different materials for jerry cans

- Prepare and clean the jerry can properly

- Take safety precautions and use the right tools when modifying the jerry can

Selecting the Right Jerry Can for Your Wood Stove

I’m trying to figure out which jerry can is the best option for my wood stove.

When it comes to choosing the right size jerry can for your wood stove, it’s important to consider the capacity and dimensions. A larger can will hold more fuel, but it may be too bulky for your space. On the other hand, a smaller can may require more frequent refills.

Additionally, it’s crucial to compare different materials for jerry cans to ensure optimal wood stove performance. Metal cans are durable and resistant to heat, but they can also be heavy. Plastic cans, on the other hand, are lightweight and easier to handle, but may not withstand high temperatures as well.

Ultimately, finding the perfect jerry can for your wood stove is about balancing capacity, dimensions, and material for efficient and safe operation.

Preparing and Cleaning the Jerry Can

Before starting to use the jerry can, it’s crucial to properly clean and prepare it by removing any dirt or residue, and then ensuring it’s completely dry. Here is the cleaning process and safety precautions to follow:

-

Rinse the jerry can with warm water and a mild detergent to remove any dirt or debris. Use a sponge or brush to scrub the inside and outside of the can thoroughly.

-

Rinse the can again with clean water to remove any soap residue. Make sure to rinse it multiple times to ensure all the soap is gone.

-

After rinsing, allow the jerry can to air dry completely. This is important to prevent any moisture from causing rust or corrosion.

By following these cleaning steps, you can ensure that your jerry can is ready for modification.

Now, let’s discuss cutting open and modifying the jerry can for ventilation.

Cutting Open and Modifying the Jerry Can for Ventilation

I’ll explain how to use a few small holes in the jerry can to provide adequate ventilation for the wood stove. When modifying the jerry can for ventilation, it is important to take safety precautions and use the right tools. Here is a table outlining the necessary steps:

| Step | Safety Precautions | Tools Needed |

|---|---|---|

| 1 | Wear protective gloves and goggles | Drill |

| 2 | Work in a well-ventilated area | Marker |

| 3 | Ensure the jerry can is empty and clean | Metal file |

| 4 | Mark the desired ventilation holes on the can | Safety glasses |

| 5 | Use the drill to create the holes | Protective gloves |

| 6 | Smooth the edges of the holes with the metal file | Goggles |

| 7 | Clean any metal shavings from the can | Clean cloth |

Adding Legs and a Base to the Wood Stove

I can attach some sturdy legs and a stable base to the wood stove to ensure it stands securely on any surface. Achieving stove stability is crucial to prevent accidents and maintain proper functioning.

When choosing materials for the legs and base, it’s important to consider their strength, durability, and heat resistance. Here are three essential elements to consider:

-

Material Selection: Opt for materials that can withstand high temperatures, such as stainless steel or cast iron. These materials are known for their strength and ability to withstand the intense heat generated by the wood stove.

-

Design and Construction: The design of the legs should provide sufficient support and stability. Consider a tripod or four-leg design for optimal balance. Additionally, ensure the legs are securely attached to the stove body to prevent any wobbling or instability.

-

Base Size and Shape: The base of the wood stove should be wide and flat enough to distribute the weight evenly, ensuring stability on various surfaces. A larger base will provide better stability, especially when using the stove on uneven or soft ground.

Testing and Using Your DIY Wood Stove

I’ve successfully tested and now use my DIY wood stove to cook meals while camping. It’s a simple yet effective solution for outdoor cooking. However, before using it, I took several testing techniques and safety precautions to ensure its efficiency and my own well-being.

Firstly, I conducted a leak test to ensure there were no air or gas leaks that could potentially cause a fire hazard. This involved pressurizing the stove and checking for any signs of leakage. I also tested its heat distribution by placing a pot of water on the stove and monitoring how evenly the heat was dispersed.

To further ensure safety, I implemented safety precautions such as maintaining a safe distance between the stove and any flammable objects, using heat-resistant gloves when handling the stove, and having a fire extinguisher nearby.

Using my DIY wood stove has been a game-changer for my camping trips. Not only does it provide a reliable cooking source, but it also allows me to enjoy the natural surroundings without relying on traditional campfire cooking methods. By following proper testing techniques and safety precautions, I can confidently cook my meals and enjoy the great outdoors.

Frequently Asked Questions

How Long Does It Take to Build a Wood Stove From a Jerry Can?

It takes about 2 hours to build a wood stove from a jerry can. The benefits of using a wood stove include cost-effective heating and a sustainable fuel source. Regular cleaning and maintenance ensure optimal performance.

Can I Use Any Type of Wood for the Base of the Wood Stove?

I can use different types of wood for the base of the wood stove, but it’s important to consider safety precautions when using it indoors. Proper ventilation and non-flammable materials are crucial.

Is It Safe to Use the Wood Stove Indoors?

Oh, using a wood stove indoors, what a brilliant idea! Let me enlighten you on the potential health hazards and share some precise tips for safely using one. Shall we begin?

Can I Paint the Jerry Can After Modifying It?

Yes, you can paint the modified jerry can using various painting techniques. It is important to choose a paint that can withstand high temperatures and adhere well to metal surfaces. Make sure to consider alternative fuel sources when painting for safety.

What Tools Do I Need to Build a Wood Stove From a Jerry Can?

To build a wood stove from a jerry can, I need a few tools like a jigsaw, drill, and metal file. Safety precautions are crucial, and alternative materials can be used if necessary.

Can I Use a Wood Stove Insert in a DIY Jerry Can Wood Stove?

When considering building a wood stove fireplace, it’s crucial to factor in the cost of materials and construction. However, if you’re planning to use a wood stove insert in a DIY Jerry Can Wood Stove, the cost of building a wood stove fireplace may decrease significantly. This alternative method combines affordability and practicality, making it an excellent choice for those seeking an alternative heating solution.

Can Duraflame Logs Be Used in a Wood Stove Made from a Jerry Can?

Can Duraflame logs be used in a wood stove made from a jerry can? Many DIY enthusiasts wonder about using Duraflame logs in a wood stove. While Duraflame logs are commonly used in traditional fireplaces, their use in a jerry can wood stove may not be ideal. It’s important to consider the safety and compatibility aspects of using duraflame logs in wood stoves specifically designed for them.

Conclusion

After carefully selecting the right jerry can, preparing and modifying it for ventilation, and adding sturdy legs and a stable base, your DIY wood stove is ready for testing and use.

With its compact design and efficient functionality, this wood stove provides a practical and cost-effective heating solution for outdoor activities or emergency situations.

Embrace the warmth and convenience of this homemade creation, bringing comfort and coziness wherever you go.

Growing up surrounded by the vast beauty of nature, Sierra was always drawn to the call of the wild. While others sought the comfort of the familiar, she ventured out, embracing the unpredictable and finding stories in the heartbeat of nature.

At the epicenter of every remarkable venture lies a dynamic team—a fusion of diverse talents, visions, and passions. The essence of Best Small Wood Stoves is crafted and refined by such a trio: Sierra, Logan, and Terra. Their collective expertise has transformed the platform into a leading authority on small wood stoves, radiating warmth and knowledge in equal measure.

-

Wood Stove3 months ago

Wood Stove3 months agoHow To Build A Thermoelectric Generator For A Wood Stove

-

Wood Stove4 months ago

Wood Stove4 months agoHow To Use Damper And Draft On Wood Stove

-

Wood Stove4 months ago

Wood Stove4 months agoWhen To Open And Close Damper On Wood Stove

-

Wood Stove4 months ago

Wood Stove4 months agoHow Far Does Wood Stove Have To Be From Wall

-

Wood Stove3 months ago

Wood Stove3 months agoHow Does A Circulator Wood Stove Work

-

Pellet Stoves3 months ago

Pellet Stoves3 months agoWhy Is My Wood Pellet Stove Putting so Much Soot

-

Wood Stove4 months ago

Wood Stove4 months agoWhat Can I Use As Insulation On Wood Stove Pipes

-

Pellet Stoves3 months ago

Pellet Stoves3 months agoHow to Make a Pellet Basket for Wood Burning Stoves