Understanding wood moisture content is key to preventing warping, cracking, and decay. Moisture levels cause wood to expand when water is absorbed and shrink when it dries out, which can weaken joints and compromise stability. The ideal moisture content varies with use and environment, and measuring it with appropriate tools helps you regulate and maintain wood’s health. Keep learning how proper moisture management can protect your projects and ensure long-lasting results.

Key Takeaways

- Wood moisture content indicates the amount of water present in the wood, affecting its size, strength, and stability.

- Equilibrium Moisture Content (EMC) is when wood’s moisture matches environmental humidity, minimizing movement.

- Moisture levels above 23% promote decay, while too low moisture can cause cracking and warping.

- Measuring moisture content with calibrated meters helps control drying and prevent structural issues.

- Regional climate and humidity influence ideal moisture levels for durable, stable wood use.

How Does Moisture Affect Wood?

Moisture substantially influences wood’s physical properties, as it causes the material to expand or contract depending on the water content. When moisture levels rise, wood expands; when they fall, wood shrinks. Changes in humidity affect moisture content, leading to movement in the wood’s structure. If the moisture content fluctuates beyond the wood’s equilibrium moisture content (EMC), it can cause warping, which distorts the shape, or cracking, which weakens the material. These movements are especially common when environmental conditions change rapidly. Excess moisture, above about 23%, can also promote mold, decay, and weaken joints. Understanding how moisture impacts wood helps you anticipate potential issues like buckling or gaps, and underscores the importance of managing humidity to keep moisture levels stable. Proper ventilation can help regulate moisture levels and prevent problems associated with excess water content in wood. Recognizing the impact of spatial variations in humidity can further aid in controlling moisture-related issues in wooden environments. Additionally, implementing moisture barriers can effectively reduce moisture ingress and protect wooden structures from excessive humidity. Maintaining consistent humidity levels minimizes the risk of wood distortion and prolongs the lifespan of wooden components.

The Concept of Equilibrium Moisture Content

Your wood reaches equilibrium moisture content when it matches the humidity of its environment, stopping moisture exchange. This balance depends on environmental factors like relative humidity and temperature, which can cause EMC to rise or fall. Understanding how RH influences EMC helps you predict how wood will respond in different conditions, guiding your drying and finishing decisions. Additionally, considering moisture content in textiles can offer insights into maintaining optimal wood conditions. Recognizing the effects of temperature on EMC can further refine your understanding of moisture dynamics in various climates, especially since seasonal variations play a significant role in moisture fluctuations. Being aware of wood species characteristics can also influence how moisture interacts with different types of wood in varying environments. Moreover, monitoring environmental humidity levels is crucial for accurate moisture management in woodworking projects.

Environmental RH Influence

Environmental relative humidity (RH) plays a crucial role in determining the moisture content of wood through the concept of equilibrium moisture content (EMC). When environmental RH rises, the EMC increases, causing the moisture in wood to absorb more water, which leads to expansion. Conversely, when RH drops, the EMC decreases, and the moisture content of wood diminishes, resulting in shrinking. The moisture levels in wood tend to stabilize at EMC after sufficient exposure to the environment, aligning with the surrounding humidity and temperature. This moisture in wood affects its dimensional stability and overall performance. A moisture reading that reflects the current environmental RH helps predict how the wood’s moisture content will change over time, especially as humidity increases or decreases. Understanding EMC is essential for proper wood storage and application, as improper moisture levels can lead to warping or cracking. Additionally, monitoring ambient humidity allows for better control of storage conditions, reducing the risk of spoilage signs in stored wood products that can indicate improper moisture levels that compromise quality and durability. Recognizing the importance of wood moisture content in relation to environmental factors can help prevent long-term damage and ensure the longevity of wood materials. Maintaining optimal moisture levels can also improve the workability and finish quality of wood during processing and use.

Moisture Balance Dynamics

When wood interacts with its surroundings, it naturally seeks a state of balance where its moisture content remains stable unless conditions change. This is known as the equilibrium moisture content (EMC), the moisture level at which wood neither gains nor loses water. EMC varies with environmental conditions like relative humidity and temperature; for example, at 50% RH and 70°F, it’s about 8-9%. As conditions shift, wood absorbs or releases moisture to reach EMC, causing expansion or contraction. The speed of moisture adjustment depends on factors such as thickness, grain, and air circulation. Understanding moisture balance helps you predict how wood will react and guarantees proper moisture measurement for ideal wood performance. Additionally, air quality and environmental factors can influence EMC, making it essential to consider local climate when working with wood. Recognizing the role of measurement techniques ensures accurate assessments of moisture content and prevents potential issues in wood applications. Proper ventilation and climate control can assist in maintaining stable moisture levels in wood products.

Factors Influencing Wood Movement and Moisture Changes

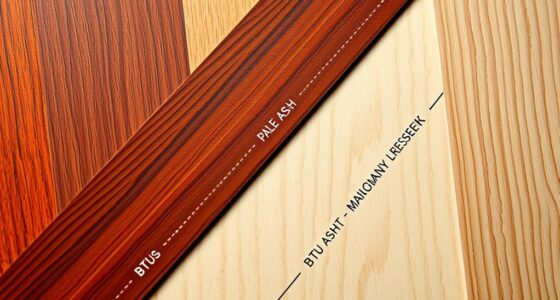

Several factors influence how wood responds to moisture changes, impacting its dimensional stability over time. Wood movement results from moisture content fluctuations caused by environmental RH. As humidity rises, wood absorbs moisture, leading to expansion; when RH drops, it releases moisture and shrinks. The equilibrium moisture content (EMC) varies with conditions, typically from 6% indoors to 14% outdoors. The extent of wood shrinkage depends on the species and grain orientation; wider boards and plain-sawn grain tend to move more. Different wood species have unique shrinkage rates, affecting how moisture changes translate into dimensional shifts. Additionally, initial moisture content, ambient temperature, and local humidity influence moisture movement. Understanding these factors helps predict and manage wood’s response to environmental moisture variations, ensuring better dimensional stability over time. Proper drying techniques and moisture measurement are essential for minimizing movement and ensuring longevity of wood products, especially when considering the wood’s intended environment. Recognizing the role of environmental conditions can further improve management strategies for wood stability. Being aware of wood species characteristics can help select appropriate materials for specific applications, reducing potential issues related to moisture fluctuations.

Acceptable Moisture Levels for Different Wood Uses

Understanding the right moisture levels is key to your project’s success. Interior wood typically needs 6% to 8%, while exterior and structural wood can range from 9% to 14%. Regional climate differences also influence acceptable moisture content, affecting both durability and structural integrity. Maintaining proper moisture content enhances the wood’s durability and health. Being aware of best beaches and regional variations can also help in selecting the most suitable wood for outdoor applications.

Interior vs. Exterior Ranges

Ever wonder how the moisture content of wood varies based on its intended use? Understanding the differences in interior versus exterior ranges helps you select the right wood for each project. For indoor applications, the ideal interior moisture content is around 6-8%, matching a relative humidity of 40-52%, which minimizes wood shrinkage and warping. In contrast, exterior moisture levels range from 9-14%, suitable for outdoor exposure but requiring careful monitoring. Using a moisture meter during the wood drying process guarantees your wood stays within the acceptable moisture range for its purpose. Factors like regional variations influence these levels, so adjusting your approach based on moisture levels for wood is essential to prevent damage and ensure longevity.

Effect on Structural Integrity

Maintaining proper moisture levels is essential for preserving the structural integrity of wood in various applications. If moisture content is too high or low, it impacts wood strength and can lead to warping and cracking, jeopardizing building stability. During the drying process, controlling moisture levels ensures the wood maintains its designed strength and prevents issues like swelling or shrinking. For interior projects, a moisture content of 6-8% is ideal, while exterior components should be kept between 9-14% to avoid fungal growth and deterioration. Excess moisture above 14% weakens fasteners and compromises structural integrity. Accurate moisture measurement before installation helps prevent future problems, guaranteeing the wood remains durable and safe for long-term use, consequently supporting the overall stability of the structure.

Regional Moisture Variations

Regional climate conditions markedly influence the acceptable moisture levels for wood used in construction and furniture. You need to measure wood moisture carefully, considering regional moisture levels and humidity levels that vary widely. For example, in Seattle, moisture content standards range from 12.2% to 16.5%, while in Las Vegas, they’re much lower, around 4.0% to 8.5%. Properly measuring wood moisture with a moisture meter ensures the wood aligns with regional climate influence, preventing warping or cracking. The wood drying process must account for regional humidity to achieve ideal moisture content, supporting wood stability. Understanding regional moisture variations helps you select appropriate moisture content standards, ensuring your wood performs well over time and resists damage caused by fluctuating environmental conditions.

Methods for Measuring Moisture Content in Wood

Measuring moisture content in wood accurately is essential for ensuring proper installation, durability, and performance. You can use moisture meters, which come in pin-type and pinless models. Pin-type meters measure electrical resistance by inserting two pins into the wood; as moisture increases, resistance decreases. Pinless meters perform a surface scan using electromagnetic sensors, providing a quick, non-invasive reading without damaging the wood. Proper calibration is vital for accuracy, often requiring adjustments based on different wood types. Many meters feature adjustable settings or correction charts to account for wood thickness and density. By choosing the right moisture meter and ensuring it’s correctly calibrated, you’ll get reliable moisture content readings, helping you make informed decisions during woodworking, construction, or repairs.

Best Practices for Controlling and Managing Moisture

Controlling and managing moisture in wood begins with creating a stable environment that minimizes fluctuations in humidity and temperature. Maintaining consistent environmental conditions helps wood reach its equilibrium moisture content (EMC) and reduces issues like warping or cracking. Use a moisture meter with species-specific settings to measure moisture content accurately during storage and installation. Aim for acceptable moisture levels that match the wood’s dry weight, preventing excessive moisture absorption or loss. To optimize drying, keep wood in a well-ventilated, dry space and avoid ground contact by storing on raised platforms. Seal indoor areas or regulate humidity to keep relative humidity between 40-60%. These practices ensure the drying process progresses smoothly and maintains consistent moisture content, reducing risks associated with moisture fluctuations.

- Regularly measure moisture content with a reliable moisture meter

- Control indoor humidity levels within recommended ranges

- Store wood on raised, dry platforms away from ground moisture

Risks Associated With Improper Moisture Levels

Maintaining proper moisture levels in wood isn’t just about preventing surface issues; it’s vital for preserving the structure’s integrity and safety. Excess moisture above 23-25% promotes mold growth and fungal decay, weakening the wood and risking structural deterioration. High moisture content also accelerates fastener corrosion, which can cause joints to fail. When moisture exceeds 14%, wood becomes prone to warping, cracking, and buckling, compromising its stability. These issues not only weaken the wood but also increase repair costs and safety hazards. Poor moisture control undermines wood integrity over time, leading to costly damage and potential safety risks. Monitoring and managing moisture content is essential to prevent these risks and guarantee the longevity and safety of your wooden structures.

Practical Tips for Maintaining Optimal Wood Moisture Content

To keep wood at its ideal moisture level, you need to take practical steps that guarantee it stays stable during storage and use. Regularly measure the wood’s moisture with a reliable moisture meter, ideally with species-specific settings, to ensure it stays within acceptable levels. Allow the wood to air dry or acclimate in its final environment for at least one to two weeks, helping to stabilize moisture content and prevent wood to shrink or crack. Control temperature and humidity to avoid fluctuations that can cause warping. Store lumber off the ground on dry, ventilated racks, and cover it loosely to prevent excess moisture absorption or loss. These practices help maintain proper moisture content, ensuring your wood remains stable and durable.

Maintaining proper moisture levels ensures wood remains stable and durable during storage and use.

- Use a moisture meter for accurate readings

- Allow time for air dried wood to stabilize

- Manage temperature and humidity consistently

Frequently Asked Questions

What Is a Good Moisture Level for Wood?

You want to know what a good moisture level for wood is. For indoor use, aim for 6% to 8%, matching your home’s humidity. Exterior wood should be between 9% and 14% to avoid problems like warping or mold. Keep your wood’s moisture content close to its environment’s EMC, within 2%, to guarantee stability. Regularly testing with a moisture meter helps maintain proper levels and prolongs your wood’s lifespan.

Is 25% Moisture Ok in Firewood?

When you ask if 25% moisture is okay in firewood, the answer is that it’s not ideal. You’ll notice it burns less efficiently, producing more smoke and creosote buildup, which can be dangerous. Firewood with 25% moisture makes it harder to start fires and doesn’t give off as much heat. For safer, cleaner burning, aim for firewood with a moisture content of 15-20%, ideally below 20%.

Will 30% Moisture Firewood Burn?

You might notice that firewood with 30% moisture burns poorly, producing more smoke and creosote buildup. In fact, wet wood like this releases about 40% less heat compared to properly seasoned wood. When you burn wood at this moisture level, you risk inefficient fires, increased emissions, and chimney hazards. To get the best heat and safety, aim for firewood with moisture content below 20%.

At What Moisture Level Does Mold Grow on Wood?

You’re wondering when mold starts growing on wood. Mold typically appears when moisture levels reach above 23%, with active growth common above 25%. If your wood’s moisture content stays below 20%, mold is unlikely to develop. To prevent mold, regularly check your wood’s moisture levels and keep them under 20%. Proper drying and monitoring are key to avoiding mold growth and maintaining healthy, durable wood.

Conclusion

Maintaining proper moisture matters more than you might imagine. By balancing, bundling, and monitoring moisture levels, you’ll prevent warping, warping, and wasted work. Staying vigilant about vapor, ventilation, and verification keeps your wood’s integrity intact. Remember, moisture management isn’t merely a measure; it’s a mindful, meticulous method to maximize wood’s durability and design. Master moisture, minimize mess—make your woodworking wondrous, worry-free, and wonderfully lasting.