You may think that finding blower bearings for a wood pellet stove seems like a daunting task. But fear not, as I am here to guide you through the procedure.

Understanding the importance of blower bearings is crucial for maintaining the efficiency of your stove. In this article, I will show you exactly where to locate these bearings and provide a step-by-step guide on how to access them.

Plus, I’ll share tips on identifying signs of damage and offer maintenance tips to extend their lifespan.

Let’s get started!

Key Takeaways

- The blower bearings on a wood pellet stove are crucial for maintaining stove efficiency and ensuring smooth and quiet operation of the blower fan.

- Proper maintenance of the blower bearings is important to prevent issues such as increased noise and decreased airflow.

- The blower bearings can be located by referring to the user manual of the wood pellet stove.

- Regular lubrication and cleaning of the blower bearings can extend their lifespan and improve overall performance.

Understanding the Importance of Blower Bearings

Understanding the importance of blower bearings is crucial for maintaining the efficiency of your wood pellet stove. Blower bearings play a vital role in ensuring smooth and quiet operation of the blower fan, which is responsible for distributing heated air throughout the stove.

These bearings are subjected to high temperatures and continuous rotational forces, making them prone to wear and tear over time. By properly maintaining and replacing blower bearings when necessary, you can prevent issues such as increased noise, decreased airflow, and reduced stove efficiency.

Exploring alternative bearing options can also be beneficial, as newer materials and designs may offer improved durability and performance.

Now that we understand the role of blower bearings in stove efficiency, let’s move on to locating them on a wood pellet stove.

Locating the Blower Bearings on a Wood Pellet Stove

To easily locate them, you’ll want to check the user manual for detailed instructions. Blower bearings are crucial components of a wood pellet stove, and troubleshooting common issues with them is essential for proper functioning.

Here are some key points to help you understand the importance of lubricating blower bearings regularly:

- Lubrication reduces friction: Proper lubrication prevents excess friction between the blower bearings and the rotating shaft, ensuring smooth and efficient operation.

- Extends bearing lifespan: Regular lubrication helps extend the lifespan of the blower bearings by reducing wear and tear caused by friction.

- Reduces noise: Well-lubricated bearings minimize noise produced during operation, contributing to a quieter and more enjoyable wood pellet stove experience.

- Improves performance: By maintaining optimal lubrication, you can ensure that the blower bearings work at their best, enhancing the overall performance of your wood pellet stove.

Understanding the importance of lubricating blower bearings regularly allows for smoother operation and increased longevity of the components.

Now, let’s move on to a step-by-step guide to accessing blower bearings.

Step-by-Step Guide to Accessing Blower Bearings

First, you’ll need to consult the user manual for detailed instructions on how to access the blower bearings on your wood pellet stove. Once you have the necessary information, follow these steps to access the blower bearings:

| Step | Procedure |

|---|---|

| 1 | Turn off the stove and unplug it from the power source. |

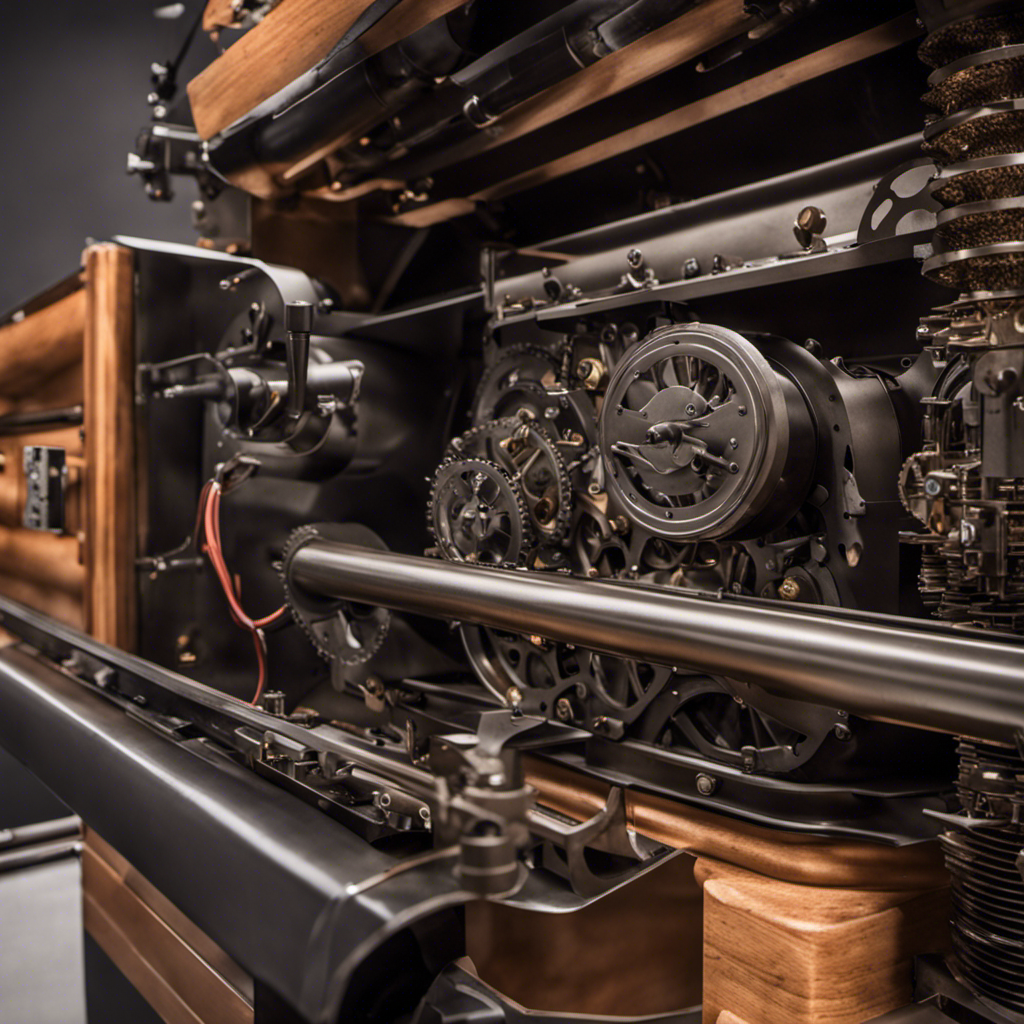

| 2 | Remove the outer casing of the stove to expose the internal components. |

| 3 | Locate the blower assembly, which is typically found near the back of the stove. |

Accessing the blower bearings will allow you to troubleshoot any issues you may be experiencing, such as unusual noises or decreased airflow. By following these steps, you can easily access the blower bearings and inspect them for any signs of damage. In the next section, we will discuss the signs of blower bearing damage and how to identify them.

Signs of Blower Bearing Damage and How to Identify Them

If you notice any strange noises or reduced airflow, these could be signs that your blower bearings are damaged and need to be inspected. Identifying blower bearing noises can help troubleshoot any potential issues.

One common noise associated with damaged blower bearings is a high-pitched squealing or grinding sound. This can occur when the bearings are worn out or lacking lubrication. Another sign is reduced airflow coming from the blower, indicating that the bearings are not functioning properly.

To identify these issues, it is recommended to visually inspect the blower for any visible signs of damage or wear, such as rust or excessive play in the fan assembly. Additionally, you can gently spin the blower wheel by hand to check for any resistance or abnormal movement.

By identifying these signs, you can take the necessary steps to address the blower bearing issues and ensure optimal performance of your wood pellet stove.

Transitioning into the subsequent section about maintenance tips for extending the lifespan of blower bearings, it is important to regularly clean and lubricate the bearings to prevent damage and ensure smooth operation.

Maintenance Tips for Extending the Lifespan of Blower Bearings

Regularly cleaning and lubricating them will help extend the lifespan of your blower bearings, ensuring smooth operation. When it comes to maintaining blower bearings, there are a few important tips to keep in mind. First, make sure to use the correct lubricant for your specific blower bearing type. Refer to the manufacturer’s guidelines for the recommended lubrication schedule and type of lubricant. Additionally, be careful not to over-lubricate the bearings as this can cause excess heat and damage. It’s also important to clean the bearings regularly to remove any built-up dirt or debris. Use a soft brush or cloth to gently remove any particles. Avoid using harsh chemicals or excessive water as this can lead to corrosion. Lastly, always inspect the bearings for any signs of wear or damage and replace them if necessary. By following these tips and avoiding common mistakes, you can ensure the longevity and optimal performance of your blower bearings.

| Tips for Lubricating Blower Bearings | Common Mistakes to Avoid |

|---|---|

| Use the correct lubricant | Over-lubricating |

| Follow manufacturer’s guidelines | Using harsh chemicals |

| Clean bearings regularly | Excessive water |

Frequently Asked Questions

How Do I Know if My Wood Pellet Stove Has Blower Bearings?

If my wood pellet stove is making strange noises or the blower is not working properly, it could be a sign of faulty blower bearings. Troubleshooting blower bearing issues may require disassembling the stove.

Can I Replace the Blower Bearings on My Own or Do I Need Professional Help?

I can replace the blower bearings on my own, but hiring a professional has its benefits. DIY blower bearing replacement allows for hands-on learning and cost savings, while a professional ensures proper installation and guarantees their work.

Are There Any Specific Tools Required to Access the Blower Bearings?

To access the blower bearings, you’ll need a few tools like a screwdriver, pliers, and maybe a wrench. Here’s a step-by-step guide on how to access the blower bearings on a wood pellet stove.

How Often Should I Inspect and Maintain the Blower Bearings?

I inspect and maintain the blower bearings on my wood pellet stove regularly. It’s important for the smooth operation and longevity of the stove. Regular maintenance benefits the stove’s performance and reduces the chances of blower bearing issues.

Can Damaged Blower Bearings Affect the Overall Performance of My Wood Pellet Stove?

Damaged blower bearings can significantly impact the overall performance and efficiency of a wood pellet stove. Signs of worn out blower bearings may include excessive noise, decreased airflow, and increased energy consumption.

Conclusion

In conclusion, maintaining the blower bearings of a wood pellet stove is crucial for its efficient performance and longevity.

By regularly inspecting and lubricating these bearings, you can prevent costly repairs and ensure the smooth operation of your stove.

Interestingly, studies have shown that proper maintenance of blower bearings can increase their lifespan by up to 50%!

So, don’t overlook this essential component of your wood pellet stove and enjoy a warm and comfortable environment for years to come.