Wood Stove

What Causes Wood Stove Back Puffing

I’ve discovered the truth behind what leads to back puffing in wood stoves, and it’s a problem that should not be taken lightly.

You see, when a wood stove fails to properly exhaust smoke, it can cause dangerous fumes to fill your home.

The culprits? Insufficient draft, clogged chimney or flue, improper airflow control, wet or green wood, and even poor wood stove design.

Stay tuned as I delve into the technical details and offer solutions to keep your home safe and cozy.

Key Takeaways

- Damaged chimney liner and inadequate insulation can lead to back puffing in wood stoves.

- Regular maintenance, including inspections and cleanings, is necessary to prevent creosote buildup and clogged chimneys or flues.

- Damaged air vents and blocked or damaged vents can result in improper airflow control and incomplete combustion.

- Using wet or green wood reduces heating efficiency, increases smoke production, and poses risks to the environment and fire safety.

Insufficient Draft

I’m experiencing insufficient draft with my wood stove, causing back puffing. It’s likely that the issue lies with either a damaged chimney liner or inadequate insulation.

A damaged chimney liner can lead to a decrease in draft, resulting in back puffing. Over time, the liner can become cracked or deteriorated, allowing smoke and gases to escape back into the house instead of being properly vented outside. This can be a serious safety concern as it can lead to a buildup of carbon monoxide.

On the other hand, inadequate insulation can also contribute to insufficient draft. Without proper insulation, the heat from the stove can escape too quickly, causing the air in the chimney to cool down and create a negative pressure, which hinders the draft.

Both of these issues need to be addressed promptly to ensure safe and efficient operation of the wood stove.

Clogged Chimney or Flue

When my chimney or flue becomes clogged, it can lead to back puffing in my wood stove. Chimney maintenance is crucial to prevent this issue.

One of the main causes of a clogged chimney or flue is creosote buildup. Creosote is a byproduct of burning wood and can accumulate on the walls of the chimney. Over time, this buildup restricts the flow of air and gases, causing improper ventilation and back puffing.

To avoid this, regular chimney maintenance is necessary. This includes annual inspections and cleanings to remove any creosote buildup. Hiring a professional chimney sweep is recommended to ensure thorough cleaning and proper maintenance.

Improper Airflow Control

Improper airflow control can result in inefficient operation and decreased heating performance of my wood stove. One common cause of improper airflow control is damaged air vents. These vents play a crucial role in regulating the amount of oxygen that enters the stove, ensuring proper combustion. If the vents are damaged or blocked, the airflow can be restricted, leading to incomplete combustion and reduced heating efficiency.

Another factor that can affect airflow control is inadequate insulation. Poor insulation around the stove can cause heat to escape, leading to a decrease in the stove’s overall efficiency. It’s important to ensure that the insulation is properly installed and in good condition to maximize the stove’s heating performance.

Now, let’s explore the impact of using wet or green wood on the wood stove’s operation.

Wet or Green Wood

Using wet or green wood in my wood stove can lead to reduced heating efficiency and increased smoke production. Wet wood contains a high moisture content, which causes the fire to burn at a lower temperature and produce less heat. In addition, the moisture in the wood creates excess smoke, which can be harmful to the environment and compromise fire safety.

To ensure efficient heating and maintain good fire safety practices, it’s important to use properly seasoned firewood with a moisture content of 20% or less. Seasoned firewood has been allowed to dry for at least six months, allowing the moisture to evaporate. This results in a more efficient and cleaner-burning fire, providing optimal heat output and reducing the risk of smoke and creosote buildup.

Transitioning to the next section about poor wood stove design, it’s important to consider the impact of stove design on heating efficiency.

Poor Wood Stove Design

I find that poor wood stove design can greatly affect the efficiency of my heating system. When the design of a wood stove is flawed, it can lead to decreased wood stove efficiency and increased smoke emission.

One of the main factors that contribute to poor wood stove design is improper airflow. If the stove doesn’t have proper air intake and exhaust systems, it can result in incomplete combustion, leading to reduced efficiency and increased smoke production.

Another aspect of poor design is the size and positioning of the firebox and flue. A small firebox can limit the amount of wood that can be burned at one time, while a poorly positioned flue can cause smoke to accumulate and back puff into the room.

Therefore, it’s essential to ensure that the wood stove has a well-designed airflow system, an appropriately sized firebox, and a properly positioned flue to maximize efficiency and minimize smoke emission.

Frequently Asked Questions

What Are Some Common Signs of Insufficient Draft in a Wood Stove?

When troubleshooting wood stove draft, it’s important to recognize common signs of back puffing. These signs include smoke entering the room, difficulty starting or maintaining a fire, and a smoky smell in the house.

How Can I Prevent My Chimney or Flue From Getting Clogged?

To prevent chimney clogs, regular chimney cleaning is crucial. Techniques such as using chimney brushes and rods can effectively remove creosote buildup. It’s important to ensure proper ventilation and draft to prevent wood stove back puffing.

What Are Some Effective Ways to Improve Airflow Control in a Wood Stove?

Improving airflow control is crucial for maximizing wood stove efficiency. By ensuring proper air intake and exhaust, you can prevent back puffing and promote better combustion, resulting in a more efficient and safer wood stove operation.

Are There Any Specific Types of Wood That Should Be Avoided Due to Their Moisture Content?

Avoid wood with high moisture content to prevent wood stove back puffing. Properly store and season wood by keeping it dry, allowing it to air-dry for at least six months. This will ensure optimal performance and reduce the risk of back puffing.

What Are Some Key Features to Look for in a Well-Designed Wood Stove?

Efficiency and safety are key features to look for in a well-designed wood stove. It should effectively burn wood, distribute heat evenly, and have a well-sealed firebox to prevent back puffing.

Conclusion

In conclusion, wood stove back puffing can occur due to various reasons. Insufficient draft, a clogged chimney or flue, improper airflow control, wet or green wood, and poor wood stove design are all potential causes.

To prevent back puffing, it’s essential to ensure proper ventilation, regular chimney maintenance, and the use of dry seasoned wood. By addressing these factors, one can enjoy a safe and efficient wood stove experience.

Growing up surrounded by the vast beauty of nature, Sierra was always drawn to the call of the wild. While others sought the comfort of the familiar, she ventured out, embracing the unpredictable and finding stories in the heartbeat of nature.

At the epicenter of every remarkable venture lies a dynamic team—a fusion of diverse talents, visions, and passions. The essence of Best Small Wood Stoves is crafted and refined by such a trio: Sierra, Logan, and Terra. Their collective expertise has transformed the platform into a leading authority on small wood stoves, radiating warmth and knowledge in equal measure.

Wood Stove

The Future of Wood Stoves: Innovations and Eco-Friendly Technologies

Looking ahead, the future of wood stoves promises cutting-edge innovations and eco-friendly technologies that could transform your heating experience—discover what’s next.

The future of wood stoves is bright, thanks to exciting innovations and eco-friendly technologies. You'll find modern stoves boasting efficiency ratings of 75% or higher, considerably cutting emissions and improving air quality. Features like smart technology let you control your stove remotely, enhancing convenience while supporting sustainable practices. Also, advanced combustion systems minimize smoke and maximize fuel use, all while adhering to stringent regulations. As you explore these developments, you'll discover the potential of cleaner fuels and community initiatives pushing for further advancements that benefit both you and the environment. There's much more to uncover about this evolving landscape.

Key Takeaways

- Modern wood stoves achieve over 75% efficiency, complying with Ecodesign regulations to improve air quality and reduce emissions.

- Smart stove technologies enable remote control and maintenance alerts, enhancing user convenience and operational efficiency.

- Advanced combustion systems, like secondary combustion, maximize fuel use while significantly lowering harmful emissions.

- Eco-friendly fuels, such as kiln-dried logs, are promoted to ensure cleaner burning and compliance with moisture regulations.

- Future trends include hybrid heating systems that integrate renewable energy sources for sustainable home heating solutions.

Historical Context of Wood Stoves

Wood stoves have long been a staple in homes, providing warmth and comfort through the ages. Over time, these heating devices have evolved considerably, focusing on enhancing combustion efficiency and minimizing harmful emissions.

Historical advancements have led to the creation of cleaner burning wood stoves, which utilize secondary combustion systems. These systems not only improve heat output but also reduce smoke and particulates, making them a more environmentally friendly option. The growing trend of investing in IRA Rollover to Gold highlights the importance of diversification, which can also reflect in how we choose heating solutions for our homes.

Despite their improvements, the U.S. certification process for wood stoves has faced scrutiny. Many consumers question the transparency of this process, which can impact consumer trust and regulatory compliance. As you consider purchasing a wood stove, it's crucial to understand how these innovations have shaped the market and your options.

Research initiatives, often funded by the U.S. Department of Energy, continue to push the boundaries of innovative wood stove technologies. These efforts aim to enhance the environmental performance of wood stoves, ensuring they remain a viable heating solution for the future.

Recent Innovations in Technology

Recent advancements in wood stove technology are changing how you can heat your home.

With enhanced combustion efficiency and smart stove integration, you can enjoy better performance while reducing your environmental impact.

Innovations such as geothermal heat pumps also illustrate the shift towards more sustainable heating solutions.

These innovations not only make your stove easier to use but also help you save on energy costs.

Enhanced Combustion Efficiency

Transforming the way we heat our homes, innovations in wood stove technology have greatly enhanced combustion efficiency. With modern wood stoves achieving ratings of at least 75% under Ecodesign regulations, you can now enjoy more efficient and eco-friendly wood heating.

Proper disposal practices for materials like paper can also reduce waste and promote sustainability in your home. Here are some key advancements contributing to this enhanced combustion efficiency:

- Secondary combustion systems: These effectively burn smoke and particulates, markedly improving overall efficiency.

- Automated air control: This technology allows stoves to self-regulate combustion conditions, leading to cleaner burns and reduced emissions.

- Moisture monitoring systems: By ensuring the right wood moisture content, these systems optimize combustion for better performance.

- Electrostatic precipitators and thermal storage solutions: These innovations help further reduce emissions while maintaining consistent heat output.

Some models, like the Skye E700, boast up to 89% efficiency through intelligent combustion management.

As you embrace these advancements, you're not only improving your home's heating but also contributing to a greener planet. With these technologies, wood stove efficiency and eco-friendliness can go hand in hand, ensuring a sustainable heating solution for years to come.

Smart Stove Integration

As technology continues to evolve, smart stove integration has become a game changer in home heating. You can now control your wood stove remotely or through voice commands, enhancing convenience like never before.

These modern stoves feature advanced combustion systems equipped with self-regulating technology that monitors wood moisture levels and enhances air intake, greatly improving energy efficiency. In addition, just as eco-friendly toilets are becoming more popular for their water-saving capabilities, these stoves are designed to minimize emissions and energy waste, contributing to a cleaner environment toilet water usage.

With built-in notifications, your smart stove alerts you when maintenance is needed, ensuring peak performance and safety. Some cutting-edge models even capture wasted heat to generate electricity, providing cost savings and a reliable backup power source.

Additionally, the latest designs incorporate eco-friendly materials and technologies, markedly reducing harmful emissions and aligning with the growing demand for sustainable heating solutions. By integrating these features, smart stoves not only improve your home comfort but also contribute to a greener planet.

In a world increasingly focused on smart home integration, these innovations make it easier for you to enjoy efficient, eco-friendly heating without compromising on convenience.

Embrace the future of wood stoves, and discover how they can enhance your home while being kinder to the environment.

Eco-Friendly Burning Methods

Eco-friendly burning methods in modern wood stoves are revolutionizing how we heat our homes. These innovations harness advanced combustion methods that considerably reduce smoke emissions while enhancing efficiency.

By adhering to Ecodesign regulations, many new wood stoves boast an impressive efficiency rating of at least 75%, with some models exceeding 89%. This means you can enjoy the warmth of your stove with a minimal environmental impact.

Additionally, just as Gold IRAs offer a tangible asset for investment, eco-friendly wood stoves provide a sustainable option for heating, aligning with a growing trend towards responsible resource management exploring gold IRAs.

Here are four key features of these eco-friendly technologies:

- Secondary Combustion Systems: These systems burn smoke and particulates, maximizing fuel use and minimizing emissions.

- DEFRA-Exempt Stoves: Specifically designed to limit smoke emissions, making them perfect for smoke control areas.

- I-Blu Combustion Intelligence: This innovation allows for real-time adjustments, ensuring ideal burning efficiency during operation.

- Cleaner Fuels: Using kiln-dried logs and seasoned wood with less than 20% moisture content promotes better combustion and reduces your overall environmental impact.

Regulatory Landscape and Compliance

As you consider upgrading your wood stove, it's essential to understand the current regulations governing smoke emissions and efficiency standards.

In the UK, compliance with DEFRA's guidelines guarantees you're using authorized fuels and appliances that minimize air pollution.

For instance, modern wood pellet stoves like the Englander 10-Cpm generate high efficiency ratings, making them a better choice for eco-conscious consumers high-efficiency ratings.

Familiarizing yourself with these rules will help you make informed choices that align with both environmental and legal requirements.

Current Regulations Overview

Maneuvering the regulatory landscape for wood stoves is essential for homeowners, especially in the UK where smoke control areas are prevalent.

To comply with these regulations, you need to understand a few key points:

- Authorized Fuels: In smoke control areas, you can only burn fuels approved by DEFRA unless you have a DEFRA-approved appliance. This is vital for maintaining air quality and avoiding hefty fines.

- Cleaner Combustion: Burning wet wood, which has a moisture content above 20%, is prohibited as it leads to higher wood stove emissions. Investing in a high-efficiency stove can help you stay compliant while also benefiting from better performance and lower emissions to assess potential risks.

- Ecodesign Regulations: New wood stoves must achieve an efficiency rating of at least 75%, ensuring high efficiency and lower emissions for better air quality.

- Independently Tested Appliances: DEFRA-exempt stoves are designed to minimize smoke emissions and must be independently tested for safety and compliance.

DEFRA Compliance Standards

Understanding DEFRA compliance standards is key to guaranteeing your wood stove operates within legal limits, especially in smoke control areas. These regulations require that you only burn authorized fuels or use DEFRA-approved appliances, minimizing wood stove emissions and adhering to strict environmental standards.

Non-compliance can lead to hefty fines, so it's essential to stay informed. Additionally, implementing diversification of retirement portfolio can be significant for long-term financial stability, much like how adhering to eco-friendly standards can secure a sustainable future.

DEFRA-exempt stoves are engineered to achieve high efficiency and must pass independent testing to confirm they meet guidelines. Under these regulations, burning wood with a moisture content exceeding 20% is prohibited, promoting the use of cleaner fuels like kiln-dried logs and smokeless fuels such as anthracite coal.

Ecodesign regulations further enhance these standards by mandating that new wood stoves achieve a minimum efficiency rating of 75%. Many DEFRA-exempt models exceed this benchmark, thereby reducing emissions and improving air quality.

Advanced Combustion Systems

Harnessing cutting-edge technology, advanced combustion systems in modern wood stoves have revolutionized the way we burn wood. By utilizing secondary combustion techniques, these systems considerably enhance efficiency and reduce harmful emissions, ensuring cleaner air for you and your family.

Additionally, as with geothermal energy's potential, integrating innovative heating solutions can lead to more sustainable practices in home energy use.

Here are four key benefits of advanced combustion systems:

- Emissions Control: They effectively reduce particulate matter (PM2.5) in exhaust, improving overall air quality.

- Self-Regulating Systems: These systems monitor wood moisture content, air intake, and combustion parameters to optimize performance, resulting in cleaner burns.

- Efficiency: Models like the Skye E700, featuring I-Blu combustion intelligence, achieve an impressive efficiency rating of 89% by continuously adjusting air introduction.

- Electrostatic Precipitators: Integrated technologies capture fine particulate matter, further enhancing emissions control.

Innovations in combustion technology not only promote cleaner burning but also capture wasted heat for electricity, which can lower energy costs and provide backup power solutions.

Smokeless Chimney Technology

With the rise of environmental awareness, smokeless chimney technology has emerged as an essential innovation for modern wood stoves. This technology enhances emissions tracking through accurate smoke measurement, utilizing light-based detection systems that measure changes in light intensity and color in smoke.

By directly measuring emissions from the flue, you gain increased accuracy and reliability over traditional methods. Additionally, incorporating AI-driven security solutions can help monitor and manage the environmental impact of wood burning in real-time, guaranteeing compliance with safety regulations.

Real-time data monitoring gives you continuous feedback on emission levels, empowering you to make prompt adjustments to maintain compliance with environmental standards. This objective data can also be invaluable if you face fines or complaints regarding emissions, as it provides verifiable evidence of compliance.

Innovations in smokeless chimney technology greatly reduce harmful particulate emissions, resulting in healthier air quality in your home and surrounding area. By adopting these eco-friendly technologies, you not only contribute to a cleaner environment but also guarantee that your wood stove operates efficiently.

Homeowners can enjoy the warmth and charm of wood stoves while knowing they're making responsible choices for both their health and the planet. Embrace smokeless chimney technology and be part of the solution for a sustainable future!

Future Market Trends

As smokeless chimney technology reshapes the wood stove landscape, the market is evolving rapidly to meet stricter environmental regulations and heightened consumer awareness about air quality.

AI advancements in AI advancements raise significant privacy concerns are also influencing product design, as manufacturers seek to integrate smart technologies that enhance user experience while addressing ethical considerations.

You're likely to notice several key trends influencing future wood stove designs:

- High Efficiency: Expect a surge in demand for clean-burning models that meet stringent emission standards.

- Hybrid Heating Systems: These innovative stoves combine wood burning with renewable energy sources, appealing to eco-conscious consumers.

- Smart Home Technologies: Remote monitoring and control features are becoming standard, allowing you to optimize fuel efficiency effortlessly.

- Advanced Combustion Technologies: Premium models are incorporating these technologies to capture wasted heat, supporting energy cost reduction and minimizing particulate emissions.

The wood stove draft prediction indicates a shift towards these eco-friendly innovations, as manufacturers respond to the growing demand for cleaner, more efficient heating options.

Research initiatives funded by the U.S. Department of Energy are driving this evolution further, ensuring that future wood stoves not only comply with emission standards but also contribute positively to air quality.

Embrace these advancements, and you'll find a market that prioritizes both performance and environmental responsibility.

Sustainable Fuel Options

Sustainable fuel options are essential for maximizing the efficiency of your wood stove while minimizing environmental impact. By choosing the right fuel, you can reduce emissions and promote eco-friendly practices. Wet wood, with moisture content over 20%, is prohibited as it results in higher emissions. Instead, opt for kiln-dried logs or properly seasoned wood, which burn cleaner and comply with regulations.

Using a moisture meter can help guarantee your wood is ready for burning. Advanced technologies, like DEFRA-exempt stoves, allow you to burn dry wood and smokeless fuels while adhering to emission standards. Here's a quick reference table for sustainable fuel options:

| Fuel Type | Moisture Content | Compliance Level |

|---|---|---|

| Kiln-Dried Logs | < 20% | High |

| Seasoned Wood | < 20% | High |

| Anthracite Coal | Smokeless option | Legal in specific areas |

| Softwood Logs | > 20% | Low |

| Wet Wood | > 20% | Illegal |

Community Engagement and Support

Community engagement plays an essential role in promoting the use of wood stoves and fostering a supportive environment for enthusiasts. By actively participating in community initiatives, you contribute to sustainability and innovation in eco-friendly technologies.

Joining a supportive network can enhance your knowledge and experience with wood stoves.

Here are some ways you can engage with the community:

- Membership Tiers: Consider joining the Fire Time Journal at various tiers like the supporter ($10/month) for basic benefits, believer ($50/month) for extra resources, or champion ($100/month) for premium content.

- Loyalty Rewards: Take advantage of the rewards system that incentivizes your participation and encourages ongoing support.

- Knowledge Sharing: Engage with fellow members to exchange ideas and experiences, fostering deeper connections and understanding of wood stove innovation.

- Community Initiatives: Get involved in local events or initiatives that promote sustainable practices and educate others about the benefits of wood stoves.

Your involvement not only enhances your own experience but also helps build a thriving, supportive community dedicated to eco-friendly technologies and sustainability.

Frequently Asked Questions

What Is the New Technology Wood Stoves?

Modern wood stoves utilize advanced combustion systems, self-regulating technology, and smart home integration. You can control them remotely, enhancing efficiency and reducing emissions, while new innovations capture fine particulates for better air quality.

Is There an Environmentally Friendly Wood Burning Stove?

Yes, you can find environmentally friendly wood-burning stoves. Look for models that meet Ecodesign regulations, like those with high efficiency and low emissions, ensuring a cleaner burn and compliance with environmental standards for smoke control areas.

What Is the Best Eco Fuel for Wood Burning Stoves?

The best eco fuel for your wood burning stove is kiln-dried logs with less than 20% moisture. Properly seasoned wood guarantees efficient burning, reducing smoke emissions and enhancing your stove's overall heating performance.

What Are the Positive Environmental Impacts of Wood Burning Stoves?

You might think wood stoves harm the environment, but they actually reduce carbon footprints by using locally sourced biomass. Plus, modern models cut emissions, improving air quality and promoting healthier communities while providing efficient heating.

Conclusion

As you look ahead, imagine cozy nights by the fire, but with cleaner air and a healthier planet. The innovations in wood stove technology are just the beginning. What if your next stove could harness advanced combustion systems and eco-friendly fuels? Picture a future where your warmth doesn't come at the cost of the environment. Stay tuned—these groundbreaking changes are on the horizon, and the way you heat your home is about to transform in ways you never thought possible.

Wood Stove

Creative Uses for Wood Stove Ashes in Your Garden and Home

Overflowing with potential, wood stove ashes can enhance your garden and home in unexpected ways—discover their surprising benefits today!

Wood stove ashes can transform your garden and home in creative ways. Start by amending your soil; the nutrients in ashes boost fertility and improve structure. They also keep pesky slugs away when sprinkled around plants. Add some to your compost for a nutrient boost, or try using them as a gentle cleaner for glass and metal surfaces. Feeling crafty? You can even make homemade soap using lye from hardwood ashes. Just remember to handle the ashes safely and keep an eye on your soil's pH. There's plenty more to discover about these versatile ash uses!

Key Takeaways

- Use wood stove ashes to amend soil, enhancing fertility and structure while neutralizing acidic pH levels for better plant growth.

- Enhance your compost by adding wood ashes, providing essential minerals and balancing pH for a wider variety of plants.

- Create a natural cleaning paste with wood ash for polishing glass and tarnished metal surfaces, offering an eco-friendly cleaning solution.

- Utilize wood ashes as a pest deterrent by sprinkling them around plants to repel slugs, snails, and ants while enriching the soil.

- Make homemade soap using wood ash lye, combining it with essential oils for customizable scents and properties in your soap products.

Amending Soil and Boosting Your Lawn

If you're looking to enhance your garden's health, wood stove ashes can be a game changer. These ashes are packed with essential nutrients like calcium, potassium, and phosphorus, making them an effective natural fertilizer. When you mix wood ashes into your soil, you can improve both fertility and structure, leading to better plant growth overall.

Additionally, incorporating wood ashes can promote better soil aeration, which is fundamental for root health, especially for plants like the String of Hearts that thrive in well-draining soil soil aeration benefits.

One of the standout benefits of wood ashes is their ability to neutralize acidic soils. With a typical pH range of 9 to 13, they help create a more balanced environment for various plants. For best results, consider applying wood ashes at a rate of 5 to 10 pounds per 100 square feet. This can greatly boost seed germination rates and improve your lawn's vitality.

Before adding wood ashes, it's wise to conduct regular soil testing. Keeping soil pH levels within the ideal range of 6.0 to 7.0 is essential for most garden plants.

Be cautious, though, as excessive wood ashes can disrupt nutrient balance and harm sensitive, acid-loving species. By using wood ashes thoughtfully, you can transform your garden into a thriving ecosystem.

Enhancing Home Compost

Wood stove ashes can also play a valuable role in enhancing your home compost. By adding small amounts of wood ash, you can improve the nutrient content of your compost bin, particularly with essential minerals like calcium and potassium. However, it's important to use wood ash wisely to avoid altering the pH levels too much.

Here's a quick overview of the benefits of using wood ash in your compost:

| Benefit | Description | Best For |

|---|---|---|

| Nutrient Boost | Adds essential minerals, enhancing plant growth | General composting |

| Wood Ash Tea | Liquid fertilizer made by soaking ashes in water | Quick nutrient delivery |

| Acid-Reducing | Balances pH for non-acid-loving plants | Diverse plant types |

| Eco-Friendly | Recycles waste and reduces synthetic fertilizer needs | Sustainable gardening |

Limit your addition to 5-10% of the total compost volume, and regularly test your compost for pH levels. This way, you guarantee the benefits of using wood ash without compromising the microbial ecosystem. Plus, your acid-loving plants will thrive with the right balance!

Natural Cleaning Solutions

While many people rely on commercial products for cleaning, natural solutions can be just as effective—and wood stove ashes are a prime example. Research has shown that using natural cleaning agents can be beneficial for both your home and the environment, similar to how cat health and nutrition promote overall well-being.

You can create a gentle abrasive paste by mixing wood ashes with water, making an excellent cleaning agent for glass surfaces like fireplace doors. This non-toxic cleaner works wonders without the harsh chemicals found in typical products.

If you've got carpets or rugs, sprinkle some wood ash on them to deodorize and eliminate odors, providing a natural alternative to commercial deodorizers. For tarnished metal surfaces, such as silverware, wood ashes can be used to create a paste that polishes effectively. Just scrub with this mixture, and you'll see those tarnished pieces shine again.

Additionally, fireplace ashes make an effective cleaning agent for pots and pans. They help remove tough stains without exposing you to harmful chemical cleaners.

Using wood ash not only keeps your home clean but also promotes sustainable practices by recycling a byproduct of wood burning. So next time you're cleaning, consider these natural cleaning solutions and the benefits of wood ashes!

Homemade Soap Production

Making homemade soap can be a rewarding and eco-friendly endeavor. You can use wood ash from hardwoods, such as ash or hickory, to create lye, an essential ingredient in the saponification process.

For a truly natural experience, consider adding essential oils for relaxation to your soap, enhancing both its scent and calming properties. Start by soaking 3 pounds of hardwood ashes in 30 gallons of water for about 4-5 days to extract the lye solution you need for soap-making.

It's vital to follow safety precautions while handling lye, as it can cause caustic burns. Always wear gloves and goggles, and work in a well-ventilated area. Measure your ingredients precisely, since even small deviations can affect the final product.

Once you've prepared your lye from the wood ash, you can mix it with oils and fats to initiate the saponification process. This chemical reaction will transform your ingredients into homemade soap, allowing you to customize scents and textures to your liking.

Pest Deterrent Strategies

Effective pest deterrent strategies can markedly enhance your gardening experience, making it more enjoyable and productive. By utilizing wood ash, you can create a natural barrier against various pests, particularly in your vegetable garden.

Exploring trending nutrition topics can also inspire you to grow organic vegetables, further improving your health. Here are some practical ways to use wood ash:

- Sprinkle around plants: Dust wood ash around your plants to deter slugs, snails, and ants. This barrier can reduce your reliance on chemical pesticides.

- Adjust soil pH: The alkaline nature of wood ash raises soil pH, making it less favorable for certain pests while promoting healthier plant growth.

- Create a pest spray: Mix wood ashes with water to develop a natural pest spray. This boosts plant health without introducing harmful chemicals.

- Reapply regularly: After rain, reapply wood ash to maintain its effectiveness in repelling pests and keep your plants safe.

Using wood ash not only helps in pest deterrence but also enriches your soil with essential nutrients, enhancing overall garden productivity.

Environmental and Safety Considerations

When using wood stove ashes in your garden, it's essential to contemplate both environmental impacts and safety measures. Wood ash can be a sustainable alternative to synthetic fertilizers, offering vital nutrients and promoting soil health, similar to how a home cleaning service can enhance your living environment.

However, you must regularly monitor soil pH, as excessive application can lead to over-alkalinity, which might harm acid-loving plants.

Additionally, avoid using ashes from treated wood. These can contain harmful chemicals and heavy metals that could contaminate your soil and plants.

To guarantee your safety while handling wood ash, it's wise to wear gloves and other protective gear to prevent skin irritation.

Proper disposal methods are also important. Store wood ashes in a dry, non-combustible container, kept away from flammable materials to mitigate fire hazards.

Frequently Asked Questions

What Plants Like Wood Stove Ash?

If you're considering plants that thrive with wood stove ashes, you'll find tomatoes, peppers, and roses benefit greatly. Brassicas like cabbage and broccoli also appreciate the added nutrients, improving their growth and overall health.

What Can You Do With the Ashes From a Wood Stove?

Imagine tossing a handful of stardust! You can use wood stove ashes for natural fertilizer, pest control, or even as an eco-friendly de-icer. Get creative and transform those ashes into something beneficial for your space.

Are Ashes From a Wood Stove Good for Your Garden?

Yes, ashes from a wood stove can benefit your garden. They're rich in nutrients, help raise soil pH, and deter pests. Just make sure to test your soil before applying to avoid nutrient imbalances.

Which Plants Do Not Like Wood Ash?

Did you know that nearly 40% of garden plants prefer acidic soil? If you're gardening, avoid using wood ash around acid-loving plants like blueberries and azaleas, as it raises pH levels and can harm them.

Conclusion

Incorporating wood stove ashes into your garden and home is like giving your plants a warm hug, nurturing their growth and health. Just as a cozy fire brings comfort on a cold night, those ashes can enhance your soil, deter pests, and even clean your home. So, next time you stoke your fire, remember those ashes hold the potential to transform your space, making it not just greener, but also more sustainable. Embrace the warmth!

Wood Stove

Wood Stove Efficiency Ratings Explained: What the Numbers Mean

How do wood stove efficiency ratings impact your heating costs and comfort? Discover the crucial details behind these important numbers.

Wood stove efficiency ratings tell you how well a stove converts fuel into usable heat, typically ranging from 67% to 83%. Higher ratings mean better heating efficiency and lower energy costs. You'll encounter two main types of ratings: EPA ratings, which indicate emissions and performance under controlled tests, and real-world efficiency ratings that reflect actual usage. Factors like fuel quality, maintenance, and environmental conditions also affect efficiency. Understanding these ratings can help you choose the right stove for your heating needs. Stick around to discover more about what these numbers can really mean for your home.

Key Takeaways

- Wood stove efficiency ratings range from 67% to 83%, indicating how effectively fuel is converted into usable heat.

- Non-catalytic stoves have efficiencies of 67%-75%, while catalytic stoves can achieve 75%-83% efficiency.

- High Efficiency ratings lead to reduced heating costs and improved comfort in homes.

- The EPA sets emissions limits to improve air quality, with modern stoves designed to comply with stricter regulations.

- Efficiency ratings can differ between EPA testing conditions and real-world performance, so consider both for accurate assessments.

Importance of Efficiency Ratings

When you're considering a wood stove, understanding efficiency ratings is essential for making an informed choice. Efficiency ratings indicate how much of the fuel you burn converts into usable heat, with higher ratings—typically between 67% and 83%—signifying better performance.

For instance, the BTU rating of the Englander 10-Cpm shows how efficiency can enhance heating capabilities. This directly translates to reduced energy costs and increased comfort in your home.

The Environmental Protection Agency (EPA) has established standards for emissions and efficiency, emphasizing the importance of efficiency in minimizing environmental impact. By focusing on efficiency ratings, you can compare different stove models effectively, as testing methods and fuel types can lead to discrepancies in reported figures.

It's important to recognize that real-world performance may differ from laboratory tests. Non-catalytic stoves usually show efficiency ratings between 67% and 75%, while catalytic stoves can reach 75% to 83%.

This variability underlines the necessity of context when interpreting these ratings. Ultimately, a stove's efficiency rating can greatly influence your heating costs and overall comfort, making it a critical factor in selecting the right heating appliance for your home.

Types of Efficiency Ratings

Understanding the types of efficiency ratings is essential for selecting the right wood stove. There are primarily two categories of efficiency ratings you should be aware of: EPA ratings and real-world efficiency ratings. EPA ratings focus on emissions and efficiency under standardized testing conditions, expressed as a percentage. This percentage indicates how much usable heat you can derive from the total heat potential of the fuel consumed.

Additionally, investing in a wood stove can provide potential tax advantages associated with IRA accounts that might be beneficial for your overall financial strategy.

Non-catalytic wood stoves generally have efficiency ratings ranging from 67% to 75%, while catalytic stoves boast higher efficiencies, between 75% and 83%. However, keep in mind that different manufacturers might use varying testing methods for these ratings, leading to discrepancies in reported figures. This is why it's important to research and compare models carefully.

Additionally, total efficiency ratings measure the heat delivered to your home against the fuel consumed, which is often more relevant than combustion efficiency when you're evaluating options for home heating. By understanding these efficiency ratings, you can make more informed decisions about which wood stove will best meet your heating needs.

Understanding High Vs. Low Heating Value

In the world of wood stoves, differentiating between High Heating Value (HHV) and Low Heating Value (LHV) is vital for making informed decisions. The high heating value measures the total heat produced when wood burns, including the heat of vaporization of water. Typically tested at 19%-25% moisture content, HHV provides a realistic indicator of heating performance for consumers, similar to how geothermal energy utilizes the earth's internal heat for efficiency.

On the other hand, LHV only considers the usable heat, excluding the heat of vaporization, and is often tested at 0% moisture content. This can lead to artificially high efficiency numbers that may mislead you.

The Environmental Protection Agency (EPA) recognizes HHV as a standard for evaluating wood heating performance, while LHV is not, adding to the confusion regarding actual heating efficiency.

Since burning wood with moisture content higher than 0% is common, relying on HHV gives you a more accurate reflection of real-world performance in home heating.

Many manufacturers don't specify which heating value they use in their efficiency ratings, so it's important to ask whether they're referencing HHV or LHV when evaluating stove performance. This will guarantee you make a truly informed choice.

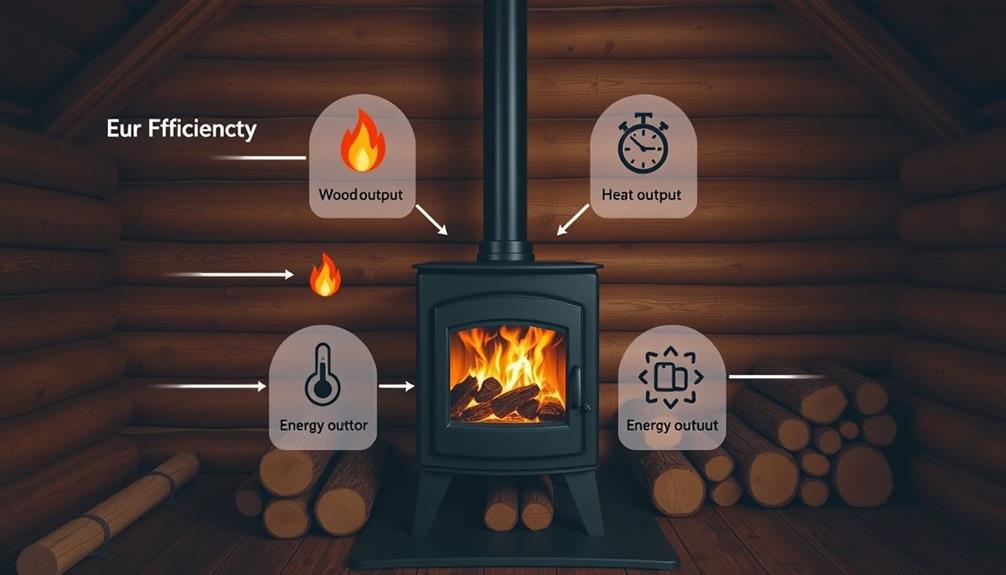

Factors Influencing Efficiency

Efficiency in wood stoves often hinges on several key factors that can greatly impact performance. One vital aspect is the placement of ducts. If your ducts are in conditioned spaces, you'll minimize heat loss, while poorly placed ducts can result in losses of up to 20%.

Regular maintenance is also essential for preserving stove efficiency; cleaning components prevents build-up that hinders performance. For ideal home heating solutions, consider the importance of choosing a service that specializes in efficient systems to keep your environment comfortable.

The quality of the fuel you use plays a notable role, too. Burning dry wood is essential for ideal combustion efficiency and heating output. If you burn wood with high moisture content, you'll notice a drop in performance.

Additionally, external factors shouldn't be overlooked. Local climate conditions and the quality of your home's insulation can affect your stove's overall efficiency. Poor insulation can lead to increased heating demand, forcing your stove to work harder than necessary.

Lastly, while stove operation modes are important, remember that high burn rates generally yield better efficiency, though they can increase venting losses. By understanding and managing these factors, you can considerably enhance your wood stove's efficiency, ensuring you get the most out of your investment.

Operating Modes of Wood Stoves

When you use a wood stove, you'll notice two main operating modes: low burn and high burn.

In low burn mode, you'll maintain steady temperatures, which can be beneficial for consistent heating, but it mightn't be the most efficient choice.

On the other hand, high burn rates can heat your space quickly, though they require careful management to avoid heat loss.

Understanding the impact of heat pump performance can provide insights into optimizing your heating methods for greater efficiency.

Low Burn Mode

Operating a wood stove in low burn mode can be beneficial for maintaining steady temperatures and enhancing fuel efficiency. This mode prolongs the burn time of your fuel, allowing for a consistent release of heat over an extended period.

While it's great for moderate heating needs, keep in mind that low burn can lead to incomplete combustion, which may produce more creosote. This means you'll need to perform chimney maintenance more frequently. Additionally, just as improper items can lead to plumbing issues, certain materials can also affect combustion efficiency; for instance, burning wet wood can lead to increased emissions and creosote buildup flushing improper items.

In low burn mode, your stove typically operates with reduced airflow, which can decrease its overall efficiency in converting fuel to heat compared to variable burn settings. If you consistently run your stove in this mode, you mightn't maximize its efficiency, which could lead to increased emissions. This can impact air quality, so it's essential to balance your heating needs with the stove's operational modes.

While enjoying the benefits of low burn, consider the potential downsides, like less heat output and the need for more maintenance. Understanding how to effectively use low burn mode can help you create a cozy atmosphere while being mindful of your stove's performance.

High Burn Rate

Achieving ideal heat output with your wood stove often involves utilizing high burn rates, which can quickly warm larger spaces. By operating in high burn mode, you can maximize combustion rates, improving efficiency and reducing unburned fuel and particulate emissions. This approach not only heats effectively but also enhances your stove's overall performance.

In a farmhouse setting, where open spaces and natural light are emphasized, efficient heating is vital for maintaining comfort throughout the home. By creating a cozy atmosphere with your stove, you can complement the key elements for farmhouse bedroom design that prioritize comfort and warmth.

However, managing high burn rates is essential. If not handled properly, you might experience increased venting losses. Here are some tips to keep in mind:

- Adjust fan speeds and airflow settings to maintain ideal combustion.

- Monitor your stove's temperature to prevent overheating.

- Verify your wood is seasoned for better combustion.

- Regularly clean your stove to avoid buildup affecting efficiency.

- Consider your stove's design and installation to maximize performance.

When using pellet stoves, you'll find that higher efficiencies often occur at elevated burn rates compared to low burn modes. Embrace the high burn rate wisely, and you'll enjoy a cozy, warm home while maximizing high efficiency.

Maintenance for Optimal Performance

To keep your wood stove running efficiently, regular cleaning practices are essential. This includes checking for buildup in the flue and ensuring that air circulation is ideal, as poor airflow can lead to inefficient burning.

You should also prioritize using quality fuel, as it greatly affects performance and maintenance frequency. Additionally, consider the benefits of using ozone air purifiers for improved air quality in your home.

Regular Cleaning Practices

Regular cleaning practices are vital for maintaining your wood stove's efficiency and safety. Neglecting this significant upkeep can lead to a dangerous build-up of creosote, which not only increases the risk of chimney fires but also reduces your stove's overall performance.

To keep your wood stove running smoothly, follow these guidelines:

- Clean the flue and chimney at least once a year, or more often if you use the stove heavily. Regular maintenance guarantees longevity and efficiency, similar to how pool heater maintenance can enhance performance.

- Remove ash ideally after every use or every few days of operation to prevent obstruction of airflow.

- Wipe the glass door with a non-abrasive cleaner periodically to guarantee visibility and proper heat distribution.

- Inspect seals and gaskets regularly for wear, enhancing combustion efficiency and extending your stove's lifespan.

- Schedule a professional inspection if you notice any unusual performance issues.

Quality Fuel Selection

Choosing the right fuel for your wood stove is essential for maintaining its efficiency and maximizing performance. Opt for high-quality fuel, such as seasoned hardwood with a moisture content of 19%-25%. This type of wood enhances combustion efficiency and maximizes heat output.

Additionally, selecting the right fuel is similar to picking the best dog names and breeds for your furry companion, as both choices can greatly impact overall satisfaction. On the other hand, using low-quality or green wood leads to increased creosote buildup, reducing stove efficiency and raising emissions, which could create safety hazards.

Proper fuel storage is also key. Keep your wood in a cool, dry place to prevent moisture absorption, ensuring it burns well when you need it.

Regularly inspect and clean the stove's combustion chamber to improve airflow; this maintenance is vital and can be influenced by the quality fuel selection you make. Additionally, pay attention to the ash content of your fuel. Choosing pellets with lower ash content can decrease your cleaning frequency and enhance overall efficiency.

Professional Installation Importance

Selecting high-quality fuel is just one part of guaranteeing your wood stove operates efficiently.

Professional installation plays an important role in maximizing that efficiency. When a qualified technician handles your stove setup, they make sure everything's positioned correctly, minimizing heat loss and enhancing performance. Misplaced ducts can lose up to 20% of heated air, so the right placement is vital.

Here are some key benefits of professional installation:

- Optimized duct placement for better heat distribution

- Reduced risk of airflow issues that can hinder efficiency

- Compliance with safety standards to keep your home safe

- Regular maintenance and inspections to extend your stove's lifespan

- Expert advice tailored to your home's layout

Environmental Impact of Emissions

Wood stove emissions greatly impact air quality and public health. When you burn wood, harmful pollutants like carbon monoxide and particulate matter are released into the atmosphere. These emissions contribute to respiratory issues and environmental degradation, making it vital for you to be aware of what your wood stove emits.

The EPA has made strides to combat this by setting stringent emissions limits, reducing the allowable particulate emissions from 4.5 g/hr to 2.5 g/hr by May 2020. Modern wood stoves, especially hybrid models, typically burn cleaner than older non-catalytic designs, markedly lowering emissions while maintaining high efficiency.

However, keep in mind that real-world performance can vary based on the quality of the fuel and its moisture content, which means you need to choose your wood wisely.

As the EPA continuously updates regulations, manufacturers are held accountable for complying with evolving standards for cleaner combustion. By understanding these emissions and their environmental impact, you can make informed decisions that contribute to better air quality and public health.

Your choice of wood stove matters—not just for efficiency, but for the environment, too.

Comparing Wood Stove Brands

When comparing wood stove brands, you'll want to look closely at their efficiency ratings and how they stack up against emissions standards.

Some brands may shine in efficiency but falter in compliance, while others might prioritize transparency in fuel type considerations.

Understanding these factors will help you make an informed choice for your heating needs.

Brand Efficiency Comparisons

Comparing wood stove brands involves more than just looking at aesthetics; it's crucial to evaluate efficiency ratings and emissions standards.

You'll want to explore how each brand stacks up regarding performance, as these can vary considerably. For instance, while non-catalytic wood stoves often sit between 67% and 75% efficiency, catalytic models can offer up to 83%.

Here are some key points to examine when choosing your wood stove:

- EPA Emissions Ratings: Look for models that meet the 2.5 g/hr standard.

- Real-World Efficiency: Brands may report efficiency using milled lumber, but check real-world performance with cordwood.

- High-Efficiency Models: Some brands can drastically lower your energy consumption and utility bills.

- Catalytic Combustor Durability: Hybrid stoves may maintain efficiency for over nine years.

- Brand Reputation: Research customer reviews and long-term performance to gauge reliability.

Taking the time to compare these factors can help you find a wood stove that not only looks good but also delivers on efficiency and effectiveness, ensuring you get the most value for your investment.

Emissions Standards Compliance

Understanding emissions standards compliance is vital for anyone looking to purchase a wood stove. The EPA has set stricter emissions limits for wood-burning appliances, reducing the allowable emissions from 4.5 g/hr to 2.5 g/hr by May 2020. This change guarantees that newer models are designed with updated environmental standards in mind.

When comparing wood stove brands, it's crucial to highlight that all Kuma Stove models are certified under current EPA standards, reflecting their dedication to cleaner burning technologies.

If you're considering hybrid stoves, take a look at options like the K-180 Series. These stoves emit considerably lower levels of pollutants compared to traditional non-hybrid models, thanks to advancements in emissions technology.

The use of catalytic combustors in hybrid stoves allows for cleaner burning at lower temperatures, which further reduces particulate emissions while improving overall efficiency.

Remember, compliance with emissions standards not only enhances air quality in your home but also aligns with broader sustainability goals.

Fuel Type Considerations

Choosing the right fuel type can greatly impact your wood stove's efficiency and performance. When it comes to wood, the type and quality you use directly affect the burn rate and overall efficiency of your stove.

For instance, hardwood typically burns longer and hotter than softwood, providing more BTUs due to its density and lower moisture content.

Here are some key considerations for selecting fuel:

- Wood Type: Opt for hardwoods like oak or maple for better heat output.

- Moisture Content: Use seasoned wood with less than 20% moisture to maximize efficiency.

- Burn Rate: Understand how different fuels influence how quickly they burn and how much heat they produce.

- Brand Variability: Different brands may have varied testing methodologies, so check for accurate comparisons.

- Real-World Performance: Remember that EPA ratings are based on controlled tests, which can differ from your actual burning conditions.

Regulatory Standards for Efficiency

Regulatory standards for wood stove efficiency play a crucial role in reducing emissions and promoting cleaner air. The Environmental Protection Agency (EPA) has set strict emissions limits for wood-burning appliances, requiring a maximum of 2.5 grams of particulate matter per hour for stoves manufactured after May 2020.

This regulation guarantees that the stoves you choose aren't only efficient but also environmentally friendly.

The New Source Performance Standards (NSPS) have evolved since their introduction in 1988, continually tightening emissions regulations for wood-burning appliances. By complying with these standards, manufacturers like Kuma Stoves assure that their models meet the latest efficiency and emissions requirements.

In Ireland, Building Regulations Part L aligns with the EU's Ecodesign requirements, mandating minimum efficiency standards for stoves.

This legislation encourages the adoption of cleaner heating technologies. Additionally, the Sustainable Energy Authority of Ireland (SEAI) offers grants to support homeowners in shifting to energy-efficient heating systems, helping you meet these regulatory standards.

Tips for Choosing Efficient Stoves

With the right information in hand, selecting an efficient wood stove can greatly enhance your home's heating experience while being environmentally responsible.

To make the best choice, keep these tips in mind:

- Look for efficiency ratings between 67%-83% for catalytic stoves, guaranteeing superior heat retention and lower emissions.

- Prioritize models certified under the latest EPA standards, which limit emissions to 2.5 g/hr, contributing to improved air quality.

- Check the BTU output; an ideal range of 15,000-50,000 BTUs will guarantee your stove meets your heating needs without wasting fuel.

- Research the type of wood you plan to use; burning dry wood with a moisture content below 20% maximizes efficiency and minimizes creosote buildup.

- Read user reviews to find models that not only promise high efficiency ratings but also maintain performance over time and require minimal maintenance.

Frequently Asked Questions

What Is a Good Efficiency Rating for a Wood Stove?

A good efficiency rating for your wood stove falls between 67% and 83%. Non-catalytic models usually hit 67%-75%, while catalytic ones can reach 75%-83%. Higher numbers mean better heat retention and lower heating costs.

What Is 80% Efficient Wood Burning Stove?

An 80% efficient wood-burning stove converts most of the wood's heat into warmth for your home. You'll save on fuel costs and reduce emissions, enjoying a cozy atmosphere while being environmentally friendly.

What Is a Good BTU Rating for a Wood Stove?

A good BTU rating for your wood stove typically ranges from 15,000 to 50,000. It depends on your space size; larger rooms need higher BTUs for effective heating, ensuring your comfort throughout the day.

What Is 90 Percent Efficient Wood Stove?

Think of a 90 percent efficient wood stove as a master chef, crafting heat from wood with precision. You'll enjoy cozy warmth while using less fuel, but remember, real-world conditions can affect that efficiency.

Conclusion

In the grand tapestry of home heating, choosing a wood stove is like selecting a trusted companion for chilly nights. By understanding efficiency ratings and their underlying meanings, you're not just ensuring warmth—you're embracing responsible comfort. Remember, a well-chosen stove can dance gracefully with the environment while keeping your space cozy. So, as you commence on this journey, let the numbers guide you to a snug haven where warmth and wisdom intertwine beautifully.

-

Wood Stove6 months ago

Wood Stove6 months agoHow To Build A Thermoelectric Generator For A Wood Stove

-

Wood Stove6 months ago

Wood Stove6 months agoHow Far Does Wood Stove Have To Be From Wall

-

Wood Stove3 months ago

Wood Stove3 months agoWhat Can I Use As Insulation On Wood Stove Pipes

-

Wood Stove7 months ago

Wood Stove7 months agoHow To Use Damper And Draft On Wood Stove

-

Wood Stove7 months ago

Wood Stove7 months agoWhen To Open And Close Damper On Wood Stove

-

Wood Stove6 months ago

Wood Stove6 months agoHow To Make A Heat Shield For A Wood Stove

-

Wood Stove6 months ago

Wood Stove6 months agoHow Does A Circulator Wood Stove Work

-

Pellet Stoves6 months ago

Pellet Stoves6 months agoWhy Is My Wood Pellet Stove Putting so Much Soot