So, your wood stove is no longer performing optimally, right? No need to worry, because I have the perfect solution for you.

In this article, I’m going to show you exactly how to paint your wood stove and give it a fresh, new look.

From choosing the right paint to sealing the final coat, I’ll guide you through each step of the process.

Get ready to transform your old wood stove into a stunning centerpiece in your home.

Key Takeaways

- Choose a heat-resistant paint specifically designed for wood stoves with high heat resistance ratings.

- Consider classic black or bold colors like red or blue for a sleek and modern look.

- Look for heat-resistant paint finishes like enamel or ceramic.

- Properly clean, sand, and prime the surface of the wood stove before applying paint for a long-lasting and protective finish.

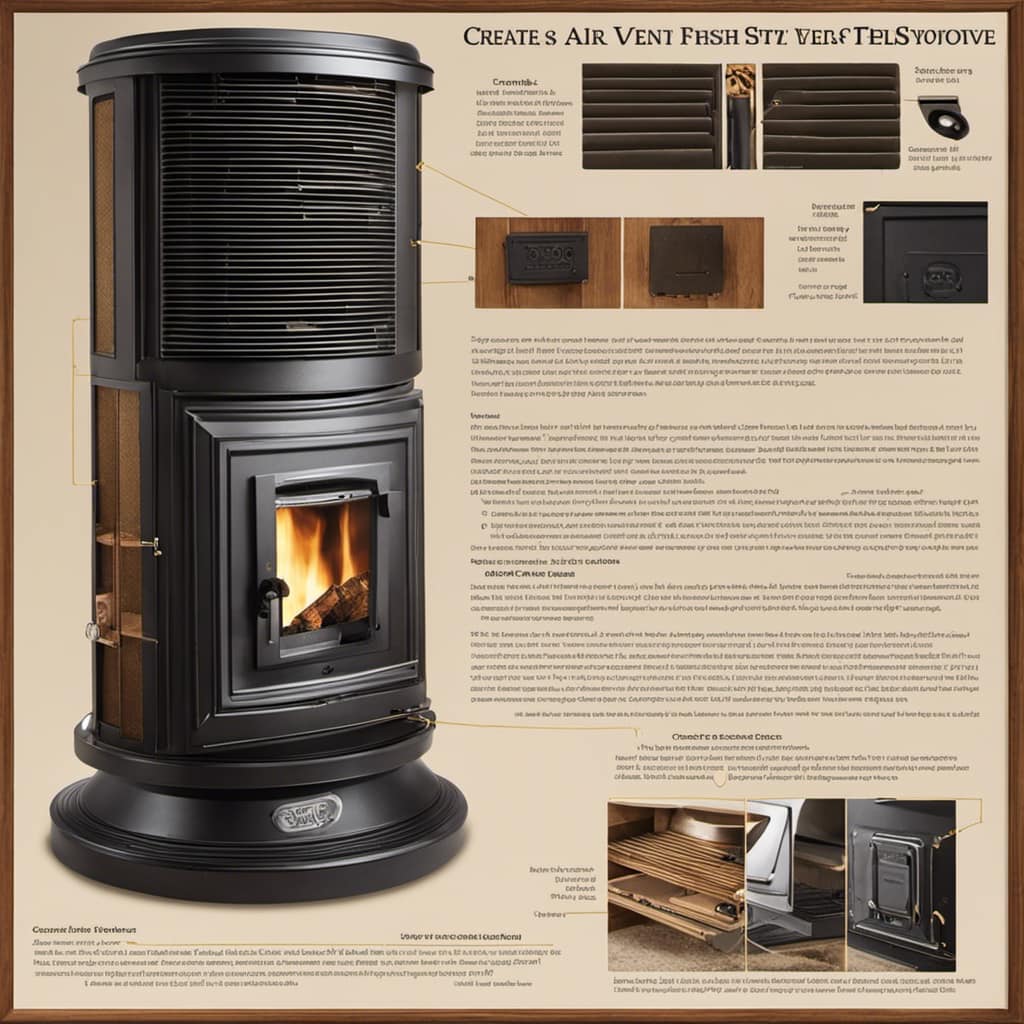

Choosing the Right Paint for Your Wood Stove

I’m considering the best paint option for my wood stove. When it comes to painting a wood stove, it’s important to choose a paint that can withstand high temperatures. Heat resistant paints are specially designed for this purpose. These paints are formulated to withstand the extreme heat produced by wood stoves, ensuring that the paint job remains intact and doesn’t peel or bubble.

There are a few key painting techniques to keep in mind when painting a wood stove. Firstly, it’s crucial to properly prepare the surface before applying the paint. This involves cleaning the stove thoroughly to remove any dirt, grease, or rust. Sanding the surface lightly can also help the paint adhere better.

Once the surface is prepared, it’s time to choose the right heat resistant paint. Look for paints that are specifically designed for use on wood stoves and have a high heat resistance rating. These paints are often made with special additives that allow them to withstand temperatures up to 1200°F or more.

When applying the paint, it’s important to follow the manufacturer’s instructions. Generally, it’s recommended to apply multiple thin coats rather than one thick coat. This ensures better adhesion and a more even finish. Allow each coat to dry completely before applying the next one.

Preparing Your Wood Stove for Painting

Before painting, I’ll make sure to thoroughly clean and sand the surface of the wood stove. Properly preparing your wood stove is essential for achieving a smooth and long-lasting paint finish.

To start, I’ll clean the stove’s surface using a mild detergent and water solution. This will remove any dirt, grease, or grime that may interfere with the paint’s adhesion.

After cleaning, I’ll inspect the surface for any rust or peeling paint. If necessary, I’ll use a wire brush or sandpaper to remove these imperfections.

Sanding the surface is crucial for creating a smooth and even base for the paint. I’ll use fine-grit sandpaper to lightly sand the entire surface of the wood stove. This will help remove any remaining debris, rough patches, or glossy areas that could prevent the paint from adhering properly.

Once the surface is clean and smooth, I’ll wipe it down with a tack cloth to remove any dust or particles left from sanding. This step is crucial to ensure the paint goes on smoothly and without any imperfections.

By following these painting techniques and properly maintaining your wood stove, you can achieve a professional-looking finish that will protect and enhance the appearance of your stove for years to come.

Now that the surface of the wood stove is clean and sanded, it’s time to move on to the next step: applying primer.

Cleaning and Sanding the Surface of Your Wood Stove

After thoroughly cleaning and sanding the surface, it’s important to wipe it down with a tack cloth to remove any dust or particles. Cleaning and sanding are crucial steps in preparing the surface of your wood stove for painting. When it comes to cleaning methods, it’s important to use a gentle yet effective approach.

Start by removing any loose dirt or debris using a soft brush or cloth. For tougher stains or grease buildup, a mild detergent or vinegar solution can be used. Avoid using abrasive cleaners or harsh chemicals that may damage the surface of the stove.

Once the stove is clean, sanding techniques can be employed to create a smooth and even surface for the paint to adhere to. Begin by using a medium-grit sandpaper to remove any rough spots or imperfections. Sand in the direction of the grain to avoid creating scratches. Afterward, switch to a fine-grit sandpaper to further smooth the surface.

Be sure to wipe away any sanding dust with a tack cloth before moving on to the painting process. This will help ensure a clean and flawless finish. By following these cleaning methods and sanding techniques, you’re taking the necessary steps to prepare your wood stove for painting. This will result in a professional-looking finish and prolong the life of your stove.

Priming Your Wood Stove for a Long-Lasting Finish

To achieve a long-lasting finish, I ensure that the surface of my wood stove is properly primed before painting.

Priming is a crucial step in prepping the wood surface for painting, as it helps to create a smooth and even base for the paint to adhere to. Additionally, it provides a layer of protection against heat damage.

Before I begin priming, I make sure to clean and sand the surface of the wood stove to remove any dirt, grease, or old paint. This ensures that the primer will properly bond to the surface and prevent any peeling or flaking in the future.

Once the surface is clean and dry, I apply a high-quality heat-resistant primer that’s specifically designed for use on wood stoves.

The primer acts as a barrier between the wood and the paint, preventing any heat damage that may occur during the stove’s operation. It also helps to seal the wood, preventing moisture from seeping in and causing warping or rotting.

Applying the First Coat of Paint to Your Wood Stove

I’m now going to guide you through the process of applying the first coat of paint to your wood stove.

It’s essential to follow proper paint application techniques to ensure a smooth and long-lasting finish.

Additionally, choosing the right type of paint is crucial for achieving the desired results and protecting your wood stove from heat and wear.

Proper Paint Application Techniques

I always ensure a smooth and even coat of paint by using long, steady brush strokes. Proper paint application techniques are essential for achieving a professional finish on your wood stove. Here are three key tips to keep in mind:

-

Clean the surface: Before applying paint, make sure the surface of your wood stove is clean and free of any dirt, grease, or rust. Use a mild detergent and a scrub brush to remove any residue, and then rinse thoroughly and allow the stove to dry completely.

-

Use the right brush: Choose a high-quality brush specifically designed for painting metal surfaces. A brush with synthetic bristles will provide a smooth application and minimize brush strokes.

-

Apply thin coats: Instead of applying a thick coat of paint, it’s best to apply multiple thin coats. This allows for proper paint drying between each coat and helps to prevent drips and uneven coverage.

Choosing the Right Paint

Now that we’ve covered the proper paint application techniques, let’s dive into the exciting world of choosing the right paint for your wood stove.

When it comes to color options, the possibilities are endless. You can go for a classic black to give your stove a sleek and timeless look. If you prefer a more modern touch, consider bold colors like red or blue to make a statement in your space.

As for the paint finish, it’s important to select one that can withstand the high temperatures your wood stove produces. Look for heat-resistant paint finishes specifically designed for stoves, such as enamel or ceramic finishes. These finishes not only provide durability but also give your wood stove a beautiful sheen.

With the right color and paint finish, you can transform your wood stove into a stunning focal point in your home.

Adding Additional Coats for a Smooth and Even Finish

After each coat of paint, I’ll check for any uneven spots and apply additional coats as needed to achieve a smooth and even finish. This step is crucial in ensuring a professional and polished look for your wood stove.

Here’s how I go about adding additional coats:

-

Applying thin layers: To avoid drips and clumps, it’s important to apply thin layers of paint. This allows for better control and ensures a more even distribution of paint. I typically use a paint sprayer for this step, as it provides a smooth and consistent application.

-

Checking for uneven spots: After each coat, I carefully inspect the surface for any uneven spots or missed areas. These can be easily corrected by applying additional coats to those specific areas. It’s important to address these issues promptly to achieve a flawless finish.

-

Sanding between coats (if necessary): If there are any rough patches or imperfections, I lightly sand the surface between coats. This helps create a smoother surface and ensures that the subsequent coats adhere properly.

Painting the Details and Accessories of Your Wood Stove

When it comes to painting the details and accessories of your wood stove, attention to detail is key.

Start by carefully selecting the color that will complement your stove and enhance its overall appearance.

Before applying the final coat, make sure to properly prep and prime the surfaces to ensure a smooth and long-lasting finish.

Color Choices for Stove

I think I’ll go for a bold red color for my wood stove. Color psychology plays a significant role in our emotions and can affect the overall ambiance of a room. Red is often associated with energy, passion, and warmth, which makes it a perfect choice for a wood stove.

However, there are other alternative finishes that you can consider as well. Here are three options to consider:

-

Black: It exudes elegance and sophistication, creating a sleek and modern look for your wood stove.

-

Metallic: This finish adds a touch of glamour and can create a focal point in your room.

-

Natural wood: If you want to maintain the rustic charm of your wood stove, a natural wood finish can be a great choice.

When choosing a color or finish for your wood stove, consider the overall theme and style of your room to ensure a cohesive look.

Now that you’ve selected your color, it’s time to move on to prepping and priming the surfaces to ensure a smooth and long-lasting paint job.

Prep and Prime Surfaces

To ensure a smooth and long-lasting finish, I need to properly prep and prime the surfaces before applying the chosen color. The best techniques for prepping and priming the surfaces involve thorough cleaning, sanding to remove any imperfections, and applying the primer in thin, even coats. This will help the paint adhere properly and create a solid foundation for the final coat.

When it comes to choosing the primer color, it’s important to select one that will complement the final paint color and provide good coverage. For lighter paint colors, a white or light gray primer works well, while for darker colors, a tinted primer in a similar shade can help achieve better color accuracy.

Once the surfaces are prepped and primed, it’s time to move on to applying the final coat.

Applying the Final Coat

The final coat should be applied in smooth, even strokes for a flawless finish.

To ensure a successful paint job on your wood stove, here are some crucial steps to follow:

-

Choose the right paint: Opt for a heat-resistant paint specially formulated for wood stoves. This will ensure durability and longevity.

-

Prepare the surface: Clean the stove thoroughly and sand any rough spots. Remove any rust or loose paint using a wire brush.

-

Apply the paint: Use a high-quality brush or roller to apply the final coat. Start from the top and work your way down, using long, even strokes. Avoid overloading the brush or roller to prevent drips and uneven coverage.

Proper drying time is essential for a lasting finish. Allow the paint to dry completely according to the manufacturer’s instructions before using the stove.

Now that you’ve applied the final coat, it’s time to move on to the next step: curing and sealing the paint on your wood stove.

Curing and Sealing the Paint on Your Wood Stove

I’m going to apply a clear sealant to protect the paint on my wood stove. Once the final coat of paint has dried, it’s important to allow the paint to cure properly. This curing process ensures that the paint bonds securely to the surface and becomes more durable.

Sealing the paint on your wood stove offers several benefits. Firstly, it provides an extra layer of protection against heat, moisture, and other environmental factors. This helps to prolong the life of the paint and prevent it from peeling or fading over time. Additionally, sealing the paint makes it easier to clean and maintain the stove, as it creates a smooth and non-porous surface that resists stains and dirt.

To give you a visual representation of the benefits of sealing the paint, here is a table that compares the before and after effects of sealing:

| Before Sealing | After Sealing |

|---|---|

| Prone to peeling and fading | Resistant to peeling and fading |

| Difficult to clean | Easy to clean and maintain |

| Susceptible to stains and dirt | Resistant to stains and dirt |

| Less durable | More durable |

Maintaining the Beauty of Your Painted Wood Stove

Maintaining the beauty of my painted wood stove is important to me, so I regularly clean and inspect it for any signs of damage. Here are a few maintenance tips that have helped me keep my wood stove looking great:

-

Clean regularly: I make sure to clean my wood stove at least once a month. I use a soft cloth or sponge and mild soap to gently wipe away any dirt or grime. Avoid using abrasive cleaners, as they can damage the paint.

-

Inspect for damage: During my cleaning routine, I also take the time to inspect the paint for any signs of chips or scratches. If I notice any damage, I touch up the affected areas using heat-resistant paint in the same color as my stove.

-

Consider color options: When painting my wood stove, I chose a color that complements my home decor and personal style. There are a variety of color options available, ranging from traditional black to more vibrant shades like red or blue. It’s important to choose a paint that’s specifically designed for high-heat environments to ensure durability.

Frequently Asked Questions

Can I Use Regular Interior Paint for My Wood Stove?

Yes, you can use regular interior paint for your wood stove, but it isn’t recommended. Using latex paint specifically designed for wood stoves is a better option.

Regular interior paint may not be able to withstand the high temperatures that wood stoves can reach, which can lead to cracking, peeling, and release of toxic fumes.

Latex paint for wood stoves is formulated to withstand extreme heat and provide a durable finish that will last longer.

How Long Should I Wait After Painting Before Using My Wood Stove?

After painting my wood stove, I wondered how long I should wait before using it. It’s important to give the paint enough time to fully cure and harden to avoid any fumes or damage. Generally, it’s recommended to wait at least 24-48 hours before using your wood stove after painting.

As for the type of paint, it’s crucial to use high-temperature paint specifically designed for wood stoves. This paint can withstand the intense heat and provide long-lasting protection.

Can I Paint the Glass Door of My Wood Stove?

Yes, you can paint the glass door of your wood stove.

When it comes to painting techniques, it’s important to use a paint that’s specifically designed for glass surfaces.

Look for a high-temperature paint that can withstand the heat generated by the stove.

Additionally, make sure to properly clean and prepare the glass before applying the paint to ensure good adhesion.

Following these steps will help you achieve a beautiful and long-lasting finish on your wood stove’s glass door.

What Type of Primer Should I Use for My Wood Stove?

When it comes to painting a wood stove, choosing the right primer is key. The type of primer you use will depend on the material of your stove. For example, if your wood stove is made of cast iron, it’s best to use a high-heat primer specifically designed for metal surfaces. This will ensure proper adhesion and durability.

As for the best paint for a wood stove, look for a high-heat paint that can withstand the extreme temperatures.

How Often Should I Repaint My Wood Stove to Maintain Its Appearance?

Repainting frequency is an important factor in maintaining the appearance of your wood stove. The best paint for wood stoves is a high-temperature paint specifically designed for this purpose.

As for how often you should repaint, it depends on various factors such as the quality of the paint used, the amount of use your stove gets, and the conditions it’s exposed to.

Generally, it’s recommended to repaint every 2-3 years to keep your wood stove looking its best.

Conclusion

In conclusion, painting your wood stove is a great way to give it a fresh and updated look. By following the right steps, you can ensure a long-lasting finish that will enhance the beauty of your stove.

Remember to choose the right paint, properly prepare the surface, and apply multiple coats for a smooth and even finish.

Don’t forget to add those little details and accessories to truly make your stove stand out. With proper care and maintenance, your painted wood stove will continue to bring warmth and style to your home.

So grab your paintbrush and get creative! Happy stove painting!

Growing up surrounded by the vast beauty of nature, Sierra was always drawn to the call of the wild. While others sought the comfort of the familiar, she ventured out, embracing the unpredictable and finding stories in the heartbeat of nature.

At the epicenter of every remarkable venture lies a dynamic team—a fusion of diverse talents, visions, and passions. The essence of Best Small Wood Stoves is crafted and refined by such a trio: Sierra, Logan, and Terra. Their collective expertise has transformed the platform into a leading authority on small wood stoves, radiating warmth and knowledge in equal measure.