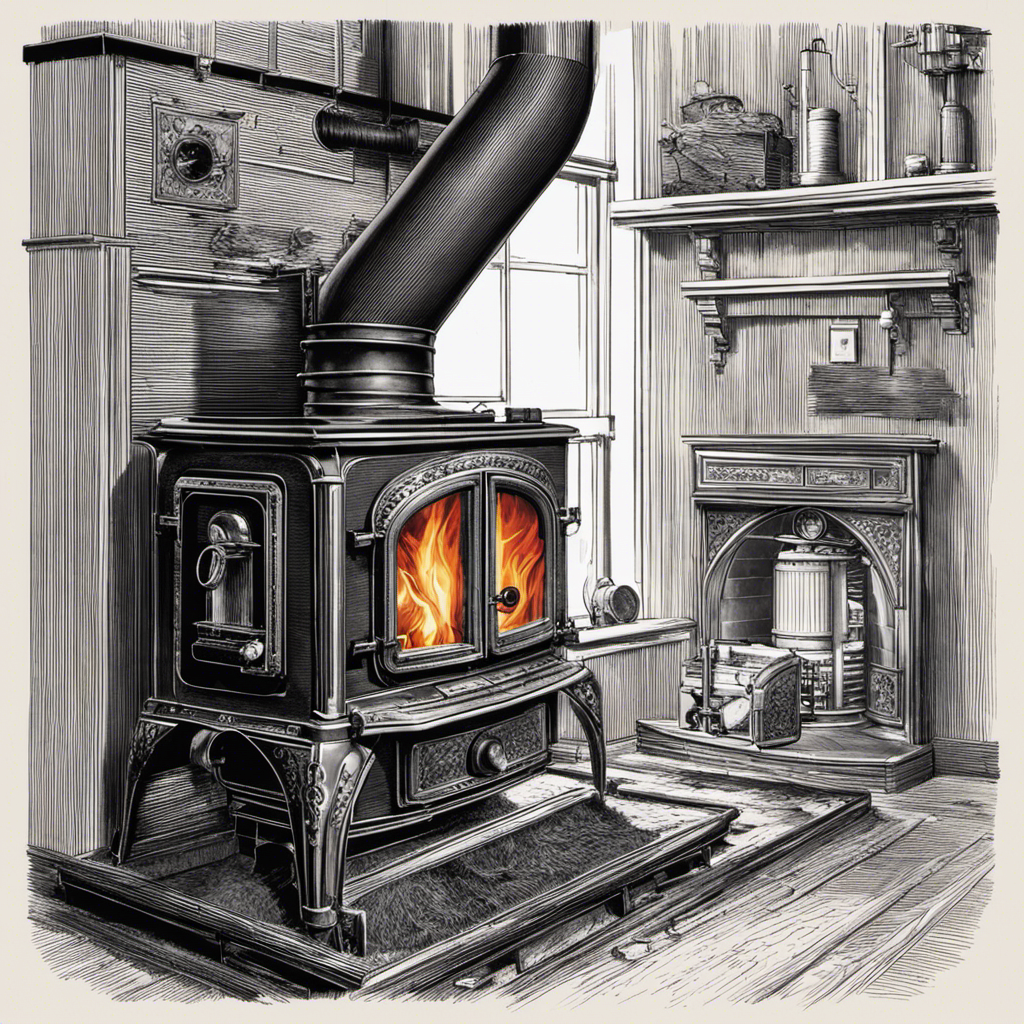

I have always had a strong passion for working in my workshop, but the constant challenge of dealing with smoke from my wood stove motivated me to create my own smokeless wood stove.

With a few materials and some careful planning, I was able to create a stove that not only heats my workshop efficiently, but also eliminates the smoke.

In this article, I’ll walk you through the step-by-step process of making your own smokeless wood stove for your workshop.

Key Takeaways

- Gathering materials and safety precautions are essential before starting the construction of a smokeless wood stove for a workshop.

- Preparing the stove’s base and structure is crucial for stability and safety.

- Building a smokeless combustion chamber with proper insulation and adjustable vents is necessary for efficient and effective burning.

- Adding insulation to the stove increases efficiency and reduces heat loss, resulting in improved heating, reduced smoke production, and increased fuel efficiency.

Gathering the Necessary Materials

I’m going to start gathering the necessary materials for the smokeless wood stove by going to the hardware store for some metal sheets and screws.

Selecting appropriate wood is crucial for the construction of a smokeless wood stove. Hardwoods like oak, maple, or birch are ideal due to their high energy content and low moisture levels. Softwoods should be avoided as they produce more smoke and creosote buildup.

Safety precautions during construction are essential to ensure a successful and hazard-free project. Wearing protective goggles, gloves, and a dust mask is necessary when handling tools and materials. It’s important to work in a well-ventilated area and avoid open flames or sparks.

Following these safety measures will ensure a safe and efficient smokeless wood stove for your workshop.

Preparing the Stove’s Base and Structure

I’ve already cleared the area and gathered all the necessary tools, so now it’s time to start building the stove’s base and structure.

To ensure a successful construction process, it’s important to consider the following factors:

-

Choosing the right location: Select an area that’s well-ventilated and away from any flammable materials to prevent accidents and ensure proper airflow for combustion.

-

Safety precautions during construction: Wear appropriate protective gear, such as gloves and goggles, to avoid injuries. Keep a fire extinguisher nearby and follow proper safety guidelines while handling tools and materials.

-

Leveling the ground: Ensure that the ground is level and stable before proceeding with the construction to maintain the stove’s stability and functionality.

-

Securing the base: Use sturdy materials like bricks or concrete blocks to create a solid base for the stove, ensuring stability and durability.

-

Building the support structure: Construct a strong and stable framework for the stove using heat-resistant materials like metal or bricks, following the manufacturer’s instructions for proper assembly.

Building the Smokeless Combustion Chamber

To ensure an efficient and effective smokeless combustion, I’ll use a combination of high-quality insulation and a well-designed airflow system.

Smokeless wood stoves offer numerous benefits for workshops, including improved air quality and reduced health risks.

When it comes to regulating airflow in the combustion chamber, there are several techniques that can be employed.

One method is to install adjustable vents that allow for precise control of the amount of air entering the chamber. This helps optimize the combustion process and minimize smoke production.

Another technique is to incorporate a secondary combustion system, which promotes the complete burning of gases and particles, further reducing smoke emissions.

Additionally, proper insulation ensures that the heat is retained within the chamber, maximizing the efficiency of the stove and minimizing heat loss.

Adding Insulation for Increased Efficiency

By applying insulation to the walls and doors of the combustion chamber, I can significantly increase the efficiency of the smokeless wood stove. Insulation plays a crucial role in preventing heat loss and ensuring that the generated heat is used efficiently. Here are some benefits of using a smokeless wood stove in a workshop:

- Improved heat retention, allowing for better heating of the workshop

- Reduced smoke production, creating a healthier working environment

- Increased fuel efficiency, saving on wood consumption

- Minimized carbon emissions, contributing to a greener workspace

- Enhanced safety, as smokeless stoves are less prone to chimney fires

To maintain a smokeless wood stove in the workshop, follow these tips:

- Regularly clean the stove to remove ash and creosote buildup

- Inspect the insulation for any signs of damage or deterioration

- Use dry and seasoned wood to prevent excessive smoke production

- Check and maintain the chimney to ensure proper ventilation

- Monitor carbon monoxide levels for a safe working environment.

Now that the insulation is in place, the next step is to test and fine-tune the smokeless wood stove for optimal performance.

Testing and Fine-Tuning the Smokeless Wood Stove

I can perform three tests and then make adjustments to fine-tune the smokeless wood stove for optimal performance.

The key to achieving a smokeless burn lies in mastering the experimentation techniques and effectively measuring and controlling airflow.

Firstly, the primary combustion air test involves adjusting the airflow to ensure complete combustion of the wood. By carefully adjusting the air intake, we can eliminate any smoke production.

Secondly, the secondary combustion air test focuses on increasing the temperature inside the stove. This is done by introducing additional air into the combustion chamber to enable the complete burn of any remaining gases.

Lastly, the smoke test allows us to assess the efficiency of the stove by analyzing the smoke output.

Frequently Asked Questions

How Long Does It Take to Gather All the Necessary Materials for Building a Smokeless Wood Stove?

It takes approximately 2-3 hours to gather all the necessary materials for building a smokeless wood stove. The required tools include a saw, drill, measuring tape, and safety goggles.

Can I Use Any Type of Wood for the Stove’s Base and Structure, or Are There Specific Types That Work Best?

For the stove’s base, it is best to use hardwoods like oak or maple, as they provide stability and durability. When selecting wood for the structure, consider softwoods like pine or fir for their ease of workability and affordability.

What Are the Potential Risks or Dangers Associated With Building and Using a Smokeless Wood Stove?

When building and using a smokeless wood stove, it is important to be aware of the potential dangers and take necessary safety precautions. This includes proper ventilation, fire prevention measures, and regular maintenance.

Are There Any Special Techniques or Tips for Adding Insulation to the Stove to Ensure Maximum Efficiency?

When it comes to insulating techniques for maximum efficiency in a wood stove, I’ve found that using high-quality insulation materials and properly sealing any gaps or cracks can make a significant difference.

How Often Should the Smokeless Wood Stove Be Tested and Fine-Tuned to Maintain Its Efficiency?

I test and fine-tune my smokeless wood stove regularly to maintain its efficiency. The testing frequency depends on usage, but I aim for at least once a year. I adjust and optimize components as needed for optimal performance.

Conclusion

In conclusion, by following these steps, you can create a smokeless wood stove for your workshop. Not only will this stove provide efficient heating, but it will also help reduce smoke and emissions.

Imagine the satisfaction of working in a clean and healthy environment, free from the nuisance of smoke.

With this smokeless wood stove, you can enjoy the warmth and comfort it brings while knowing you’re doing your part for the environment.