The widespread notion that invention stems from necessity profoundly resonates with me, especially regarding the heating of my house.

That’s why I’ve set out on a mission to build a hot water heat exchanger for the top of my wood stove.

In this article, I’ll guide you through the process step by step, ensuring that you have all the necessary materials and expertly design and build the heat exchanger frame.

Let’s get started!

Key Takeaways

- Extensive research is required to determine the appropriate size and location of the heat exchanger for optimal heat transfer and efficiency.

- Gathering and selecting materials that meet the requirements for durability and heat resistance is crucial.

- Building a sturdy and well-constructed heat exchanger frame is essential to withstand high temperatures and pressures.

- Proper installation, testing, and troubleshooting are necessary to ensure the heat exchanger functions effectively and efficiently.

Gathering the Necessary Materials

I’m currently in the process of gathering all the necessary materials for this project.

When it comes to choosing the right size for the heat exchanger, I’ve done extensive research to ensure its efficiency. The size of the heat exchanger will depend on the size of the wood stove and the amount of heat it generates. It’s important to find the right balance between the size of the heat exchanger and the amount of heat it can transfer.

Additionally, finding the best location for the heat exchanger is crucial. It should be placed in a position where it can effectively capture the heat from the wood stove and distribute it to the water.

Now that I’ve gathered all the necessary materials, the next step is to design the heat exchanger.

Designing the Heat Exchanger

Having researched extensively, I am now ready to design the heat exchanger for optimal efficiency. To ensure maximum heat transfer and minimal energy loss, it is crucial to properly size the heat exchanger. This involves considering factors such as the heat load, fluid flow rate, and temperature difference. By accurately sizing the heat exchanger, we can achieve optimal performance and energy savings.

To assist in the design process, I have created the following table, outlining the key parameters and their corresponding values for the heat exchanger:

| Parameter | Value |

|---|---|

| Heat Load | 10,000 BTU/h |

| Fluid Flow Rate | 5 gallons per minute |

| Temperature Difference | 20 degrees Fahrenheit |

Using these values, I will now proceed to determine the surface area and tube length required for the heat exchanger, taking into account heat exchanger efficiency and performance. This will ensure that the heat exchanger operates at its maximum potential, providing efficient heat transfer and ultimately reducing energy consumption.

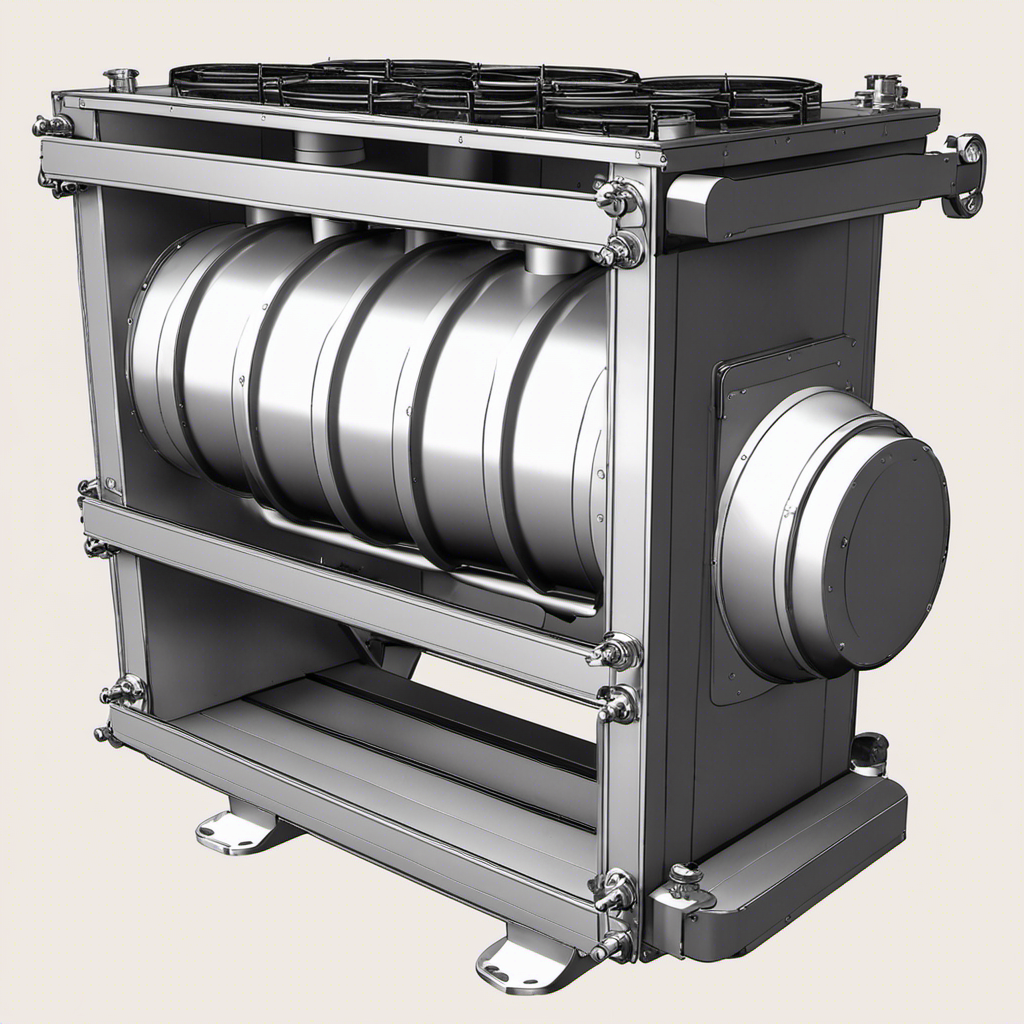

Building the Heat Exchanger Frame

To build the heat exchanger frame, I’ll gather the necessary materials and use screws to secure the metal panels together. The frame is an essential component of the heat exchanger, as it provides structural support and ensures the proper alignment of the heat transfer elements.

The metal panels will be cut to the required dimensions and then assembled using the screws. It’s important to ensure that the frame is sturdy and well-constructed to withstand the high temperatures and pressures associated with the heat exchanger operation.

Additionally, heat exchanger insulation can be added to the frame to minimize heat loss and improve energy efficiency.

Alternative heat exchanger designs may also be considered, such as plate heat exchangers or shell and tube heat exchangers, depending on the specific requirements and constraints of the application.

Installing the Heat Exchanger on the Wood Stove

I can easily install the heat exchanger on the wood stove using the provided instructions and a few basic tools. Here is a step-by-step guide to ensure a successful installation:

- Position the heat exchanger on top of the wood stove, making sure it’s centered and level.

- Secure the heat exchanger to the stove using the provided brackets or clamps. Ensure a tight and stable fit.

- Connect the inlet and outlet pipes of the heat exchanger to the existing plumbing system. Use appropriate fittings and sealants to prevent leaks.

- Test the connections by running water through the heat exchanger while the stove is in use. Check for any leaks or irregularities.

By following these steps, you can ensure a proper installation of the heat exchanger, maximizing its efficiency in transferring heat from the stove to your water system.

Now, let’s move on to testing and troubleshooting the heat exchanger to ensure optimal performance.

Testing and Troubleshooting the Heat Exchanger

How can I effectively test and troubleshoot the heat exchanger to ensure it’s functioning properly?

To begin, it’s crucial to check for any leaks in the heat exchanger system. This can be done by pressurizing the system and inspecting for any visible signs of leakage.

Additionally, measuring the temperature difference between the inlet and outlet of the heat exchanger can help identify any potential blockages or flow issues.

Another troubleshooting technique is to evaluate the performance of the heat exchanger by measuring its heat transfer efficiency. This can be achieved by comparing the temperature of the water entering and leaving the heat exchanger.

Frequently Asked Questions

How Long Does It Typically Take to Gather All the Necessary Materials for Building a Hot Water Heat Exchanger for a Wood Stove?

Typically, it takes me a few hours to gather all the necessary materials for building a hot water heat exchanger for a wood stove. The gathering time depends on the availability of the materials and their proximity.

Are There Any Specific Safety Precautions That Need to Be Taken When Designing the Heat Exchanger?

When designing a hot water heat exchanger for a wood stove, it is crucial to consider safety precautions. These include proper insulation, avoiding sharp edges, and ensuring secure connections to prevent leaks or potential hazards.

What Are Some Common Mistakes to Avoid When Building the Heat Exchanger Frame?

What are some common mistakes to avoid when building the heat exchanger frame? Ensuring proper alignment, using sturdy materials, and securing all joints tightly are crucial steps to prevent leaks and ensure efficient heat transfer.

Can the Heat Exchanger Be Installed on Any Type of Wood Stove, or Are There Certain Specifications to Consider?

Wood stove compatibility for heat exchanger installation involves considering factors such as stove design, size, and flue location. Proper clearance, heat transfer, and safety measures must be evaluated to ensure efficient and effective installation.

How Can I Determine if the Heat Exchanger Is Functioning Properly During the Testing Phase?

To test the heat exchanger, I follow a precise troubleshooting process. By checking for leaks, inspecting water flow, and monitoring temperature changes, I can determine if the heat exchanger is functioning properly during the testing phase.

Conclusion

In conclusion, building a hot water heat exchanger for the top of a wood stove is a practical way to utilize wasted heat and save on energy costs.

According to a study conducted by the U.S. Department of Energy, properly installed heat exchangers can increase the efficiency of a wood stove by up to 50%.

By following the steps outlined in this article, homeowners can harness this heat and enjoy the benefits of a more efficient heating system.