- Using cement bricks in wood stoves

- Pros and cons of using firebricks vs regular bricks in wood stoves

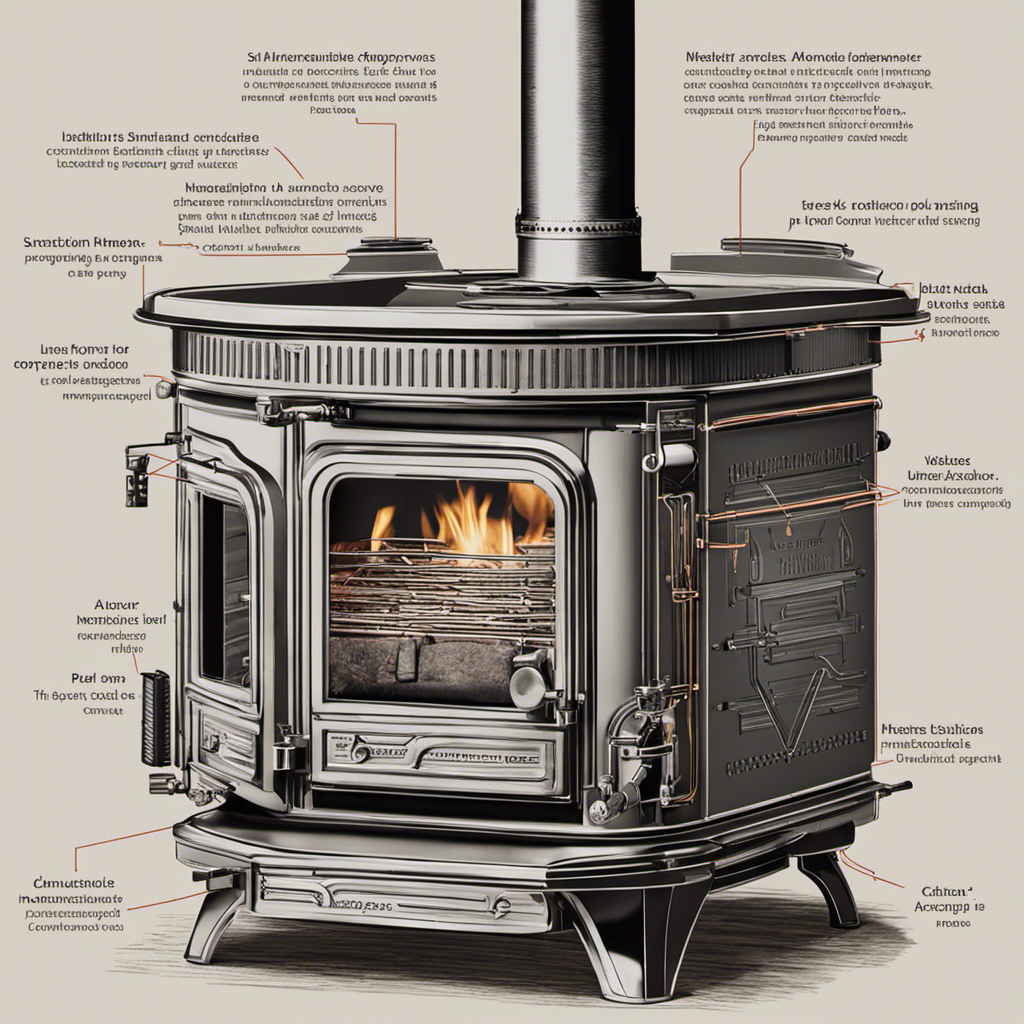

Did you know that the interior of a wood-burning stove is made with materials designed to withstand high temperatures? Firebricks, refractory cement, and thermal barrier coatings are essential components that help improve the stove’s performance in managing heat and protecting against potential damage.

In this article, I will delve into the various types of linings used in wood stoves, their functions, and the importance of choosing the right materials.

Get ready to enhance your knowledge and make informed decisions for a safer and more efficient wood stove experience.

Key Takeaways

- Firebricks and refractory cement are commonly used to line the inside of a wood stove.

- Rock wool and ceramic fiber insulation are two options for insulating the wood stove, with rock wool providing excellent fire resistance and sound absorption, and ceramic fiber insulation offering low thermal conductivity and lightweight durability.

- Thermal barrier coatings, also known as ceramic coatings or high temperature paints, can be applied to wood stoves to protect them from high temperatures and improve energy efficiency by reflecting heat back into the combustion chamber.

- Vermiculite and perlite are commonly used insulation materials in wood stoves, with vermiculite offering lightweight heat retention and perlite providing lightweight insulation with good airflow.

Firebricks

I love how firebricks retain heat and protect the inside of my wood stove. Firebrick installation is a crucial step in setting up a wood stove. These specially designed bricks are made to withstand high temperatures and keep the heat inside the stove, preventing damage to the surrounding structure.

When installed correctly, firebricks create a barrier that keeps the heat contained, ensuring efficient combustion. However, over time, firebricks may start to wear out or crack due to the extreme heat they’re exposed to. Regular firebrick maintenance is essential to ensure optimal performance and safety.

If any bricks become damaged, it’s important to replace them promptly to maintain the stove’s efficiency. Proper firebrick maintenance and replacement won’t only extend the lifespan of your wood stove but also ensure its safe and effective operation.

Refractory Cement

Using refractory cement to line the inside of my wood stove is an efficient and effective way to protect it from extreme temperatures. Refractory cement is specially designed to have high heat resistance, ensuring that it can withstand the intense heat produced by the wood stove without cracking or deteriorating. This high heat resistance is crucial for the longevity and durability of the wood stove, as it prevents the cement lining from wearing down over time.

Additionally, refractory cement provides excellent insulation, helping to retain heat within the wood stove and improving its overall efficiency. However, when considering insulation materials for a wood stove, there are other options to explore that can enhance the performance even further.

Insulation Materials

What are the different types of insulation materials that can be used to enhance the performance of a wood stove? Insulation plays a crucial role in ensuring the efficiency and safety of a wood stove. Two common types of insulation materials used in wood stoves are rock wool insulation and ceramic fiber insulation.

Rock wool insulation is made from natural basalt rock, which is melted and spun into fibers. It is known for its excellent fire resistance and high temperature resistance. Rock wool insulation is also a great sound absorber, reducing noise levels in the surrounding area.

Ceramic fiber insulation, on the other hand, is made from alumina-silica fibers. It has excellent thermal stability and low thermal conductivity, making it an ideal insulation material for wood stoves. Ceramic fiber insulation is lightweight and can withstand high temperatures, ensuring optimal heat retention and energy efficiency.

Here is a comparison table showcasing the main characteristics of rock wool insulation and ceramic fiber insulation:

| Insulation Material | Fire Resistance | Temperature Resistance | Sound Absorption | Thermal Conductivity |

|---|---|---|---|---|

| Rock Wool Insulation | High | High | Good | Moderate |

| Ceramic Fiber Insulation | Moderate | Very High | Low | Low |

Thermal Barrier Coatings

Although I’m not an expert, I’ve heard that thermal barrier coatings are commonly used to protect wood stoves from high temperatures and improve their energy efficiency. These coatings, also known as ceramic coatings or high temperature paints, are designed to withstand extreme heat and create a barrier between the hot flames and the interior of the stove.

They’re applied to the inside walls of the stove, forming a protective layer that prevents heat from escaping and reduces the risk of damage to the stove itself.

Additionally, thermal barrier coatings help to improve the overall efficiency of the wood stove by reflecting heat back into the combustion chamber, ensuring that more heat is utilized for heating the surrounding space. This not only increases the stove’s performance but also helps to reduce fuel consumption and lower energy costs.

Vermiculite or Perlite Insulation

I’ve been considering whether to use vermiculite or perlite insulation for my wood stove.

Both vermiculite and perlite are commonly used insulation materials in wood stoves, but they’ve some key differences.

Vermiculite is a naturally occurring mineral that’s lightweight and has excellent insulating properties. It’s able to withstand high temperatures and can effectively retain heat, making it an ideal choice for wood stove insulation.

On the other hand, perlite is a volcanic glass that’s also lightweight and has good insulating properties. It’s highly porous, which allows for good airflow and heat distribution. However, perlite may not be as effective as vermiculite in retaining heat.

Ultimately, the choice between vermiculite and perlite insulation depends on the specific requirements and preferences of the wood stove user. Both materials can contribute to the overall efficiency of the wood stove, but vermiculite may provide better heat retention.

Frequently Asked Questions

Can I Use Regular Bricks Instead of Firebricks in My Wood Stove?

I wouldn’t recommend using regular bricks in a wood stove. Firebricks are specifically designed to withstand high temperatures and provide better insulation. Regular bricks can crack or crumble, compromising the stove’s efficiency and safety.

How Often Should I Replace the Refractory Cement in My Wood Stove?

I replace the refractory cement in my wood stove every few years to maintain its insulation and efficiency. There are alternative insulation materials available, but it’s important to choose one that can withstand high temperatures.

Are There Any Alternative Materials to Traditional Insulation Materials for Wood Stoves?

There are alternative insulation materials for wood stoves, such as vermiculite or perlite. Vermiculite is fire-resistant and retains heat well, while perlite is lightweight but not as fire-resistant. Both have pros and cons.

Can I Apply a Thermal Barrier Coating to the Inside of My Wood Stove Myself?

Yes, you can apply a thermal barrier coating to the inside of your wood stove yourself. It’s a DIY maintenance task that offers several benefits, such as improved heat retention and increased stove lifespan.

What Are the Benefits of Using Vermiculite or Perlite Insulation in a Wood Stove?

The benefits of using vermiculite insulation in a wood stove include its ability to withstand high temperatures, its excellent insulation properties, and its resistance to corrosion. Perlite insulation also offers advantages such as lightweight, fire resistance, and low thermal conductivity.

Conclusion

After exploring the various materials that line the inside of a wood stove, it’s clear that firebricks, refractory cement, insulation materials, thermal barrier coatings, and vermiculite or perlite insulation all play crucial roles in ensuring the stove’s efficiency and durability.

These components not only provide excellent heat retention and protection against intense temperatures, but they also contribute to a safer and more effective wood-burning experience.

So, whether you’re a seasoned wood stove enthusiast or just starting out, it’s important to understand the importance of these lining materials for optimal stove performance.