Thermoelectric generators (TEGs) turn heat directly into electricity by using materials that efficiently convert thermal gradients into electrical energy. They capture waste heat from engines and industrial processes, offering a clean, solid-state method with no moving parts. While high material efficiency is key, successful scaling also depends on effective design and heat management. Continuing will show you how advances in materials and engineering are making TEGs more practical for various applications.

Key Takeaways

- Thermoelectric generators convert heat gradients directly into electrical energy using specialized materials.

- They recover waste heat from engines and industrial processes to generate electricity sustainably.

- The efficiency of TEGs depends on high-performing thermoelectric materials that maximize heat-to-electricity conversion.

- Scaling TEG systems from small devices to large power plants requires effective design and thermal management.

- Combining advanced materials and engineering enhances both the efficiency and scalability of thermoelectric power generation.

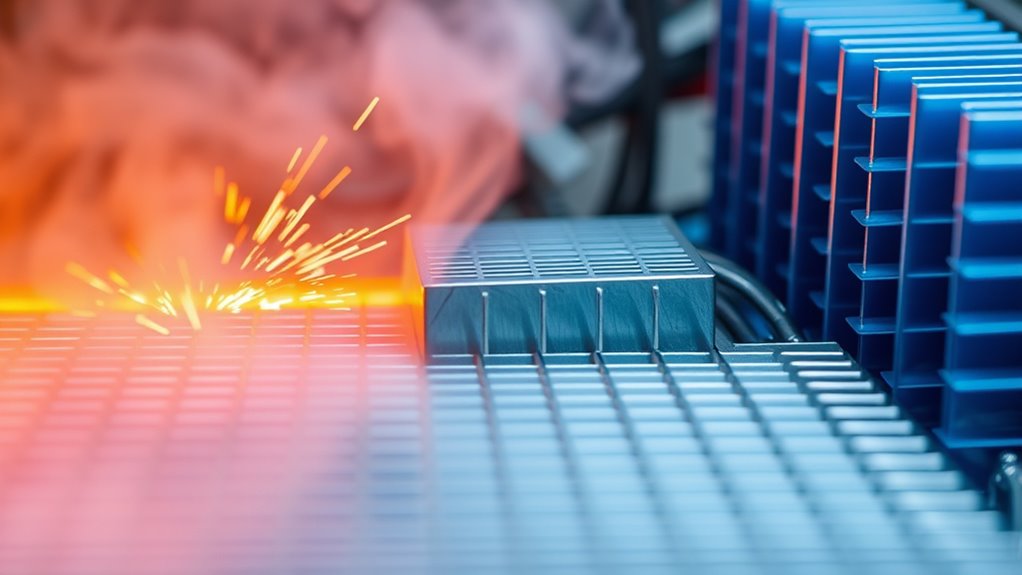

Have you ever wondered how waste heat from engines or industrial processes can be turned into useful electricity? Thermoelectric generators (TEGs) make this possible by converting temperature differences directly into electrical energy. At the heart of this technology are materials specifically designed to maximize efficiency in transforming heat into power. When you think about material efficiency, it’s all about how well these materials can convert thermal gradients into electrical current without losing much energy as heat. The better the material efficiency, the more effective your thermoelectric generator becomes, allowing you to harness more power from the same heat source. Researchers continuously seek new materials with higher thermoelectric efficiency, aiming to improve the overall performance and viability of TEGs for real-world applications. Additionally, understanding how biodiversity impacts ecosystems can inspire more sustainable energy solutions that minimize environmental disruption. Power scaling is another critical aspect you should consider. As your needs grow, so does the importance of scaling the power output of thermoelectric generators. Smaller TEGs may work well for portable devices or localized heat sources, but larger systems are necessary to power industrial equipment or generate significant electricity. Achieving power scaling means designing TEG modules that can be expanded or combined efficiently without sacrificing performance. This involves optimizing the geometry and layout of thermoelectric materials, ensuring thermal contact is maintained, and minimizing losses. When you focus on power scaling, you enable a thermoelectric system to adapt to different scales—whether it’s small gadgets or large power plants—by increasing the number of thermoelectric modules or improving the heat flow management across the system. To make thermoelectric generators practical, you need to balance material efficiency with power scaling. High-efficiency materials alone won’t guarantee a successful application if scaling up the system introduces significant losses or complexity. Conversely, a system that is easy to scale but uses inefficient materials won’t produce enough power to justify its deployment. That’s why advances in material science and engineering techniques are essential—they allow you to develop TEGs that are both highly efficient and easily scalable. This synergy between material efficiency and power scaling enables you to harness waste heat more effectively, turning a previously lost resource into a valuable source of electricity.

Frequently Asked Questions

How Efficient Are Thermoelectric Generators Compared to Other Power Sources?

You’ll find that thermoelectric generators have a lower efficiency comparison with other power sources, typically converting only about 5-10% of heat into electricity. Unlike fossil fuels or nuclear plants that boast higher energy conversion rates, thermoelectric devices are less efficient but offer advantages like solid-state simplicity and silent operation. They’re ideal for niche applications, especially where waste heat can be harnessed, but aren’t the top choice for large-scale power generation.

What Are the Main Materials Used in Thermoelectric Generators?

You’ll find that thermoelectric generators mainly use materials like bismuth telluride and lead telluride, chosen for their excellent material properties such as high electrical conductivity and low thermal conductivity. Advances in semiconductor technology constantly improve these materials, boosting efficiency. These developments enable you to harness heat more effectively, making thermoelectric generators more practical for power generation from waste heat or remote sources.

Can Thermoelectric Generators Be Used for Residential Energy Production?

You can definitely use thermoelectric generators for home installation, and they’re gaining popularity for small-scale energy production. Remarkably, a recent study shows that some systems can convert up to 10% of heat into electricity, making them efficient for certain applications. However, consider cost considerations—initial expenses can be high, but long-term savings and sustainability benefits make them worth exploring for your residential energy needs.

What Are the Limitations of Thermoelectric Generators in Hot Environments?

In hot environments, thermoelectric generators face limitations due to material degradation caused by prolonged exposure to high heat, which can reduce efficiency. Additionally, inefficient heat transfer can prevent ideal temperature differences across the device, limiting power output. You might find that these issues lead to reduced lifespan and performance, making thermoelectric generators less reliable in extreme heat unless advanced materials and improved heat transfer methods are used.

How Long Do Thermoelectric Generators Typically Last?

Think of thermoelectric generators as reliable old friends—they can last 10 to 20 years with proper care. Your lifetime expectancy depends on factors like operating conditions and material quality. Regular maintenance requirements include keeping them free of dust and ensuring proper heat flow. With good upkeep, they keep producing electricity steadily, but harsh environments may shorten their lifespan. So, monitor and maintain them to maximize longevity.

Conclusion

You now see how thermoelectric generators turn heat into electricity, offering a clean energy solution. Did you know that they can convert up to 10% of heat energy into power? That’s enough to keep small devices running or even power remote sensors. As technology advances, these generators could play a big role in sustainable energy, making heat waste a valuable resource. So, next time you feel warmth, imagine it could help power your world.