When choosing pellets, you’ll want to consider their types, shapes, materials, and quality. Domed for accuracy, hollow points for impact, and wadcutters for target shooting each serve different purposes. High-quality pellets made from pure lead or eco-friendly metals ensure better consistency and performance. The shape and weight also influence your shot’s stability and precision. To maximize your results and learn more about selecting the best pellets, keep exploring the options available.

Key Takeaways

- Different pellet types, such as domed, hollow point, and wadcutter, serve specific purposes like target shooting or hunting.

- Material quality, including purity and consistency, directly impacts pellet performance and reliability.

- Manufacturing precision and tight tolerances ensure uniform shape, size, and ballistic behavior.

- Pellet weight influences accuracy, impact energy, and suitability for different shooting distances.

- Certified pellets with standards like EN PLUS or DINPLUS guarantee safety, quality, and environmental considerations.

Different Types of Airgun Pellets and Their Uses

When choosing airgun pellets, understanding the different types and their specific uses can considerably improve your shooting performance. Airgun pellets come in various pellet types, each with unique shapes that influence pellet performance. Domed pellets, with their round noses, are aerodynamic and deliver stability and accuracy over long distances, making them ideal for target shooting. Hollow point pellets expand upon impact, providing maximum damage and reducing over-penetration, perfect for hunting at close to medium ranges. Wadcutter pellets have flat-topped shapes designed for clean paper holes, excelling in target competitions. The pellet shape directly impacts the ballistic coefficient, affecting accuracy and range. Pellet design directly influences how a pellet interacts with the air and target, affecting overall performance. Knowing these pellet types helps you select the right pellet for your activity, ensuring ideal performance and precision. Additionally, pellet quality can significantly influence consistency and overall shooting results, as high-quality pellets often feature more uniform shapes and weights that improve shot groupings.

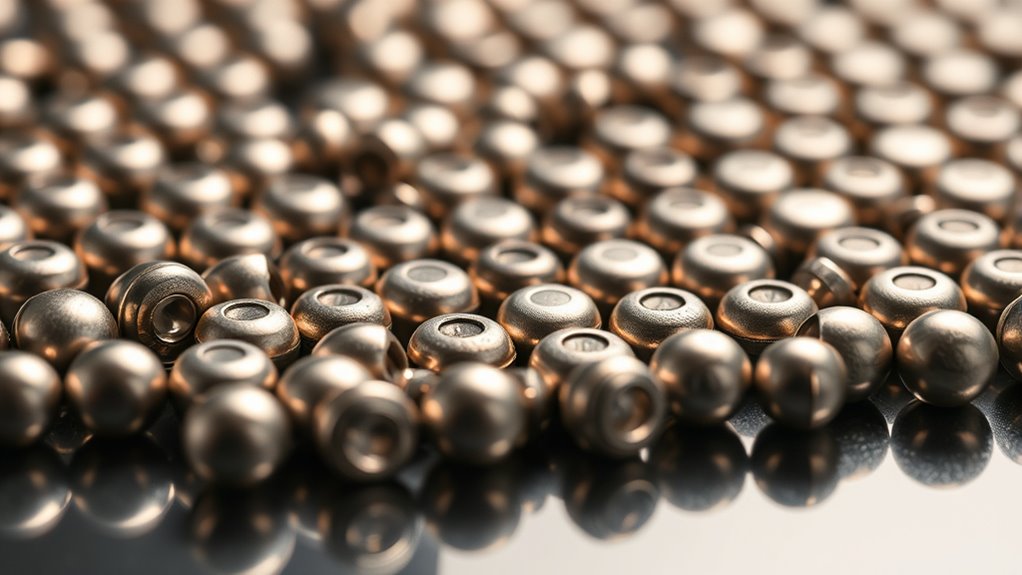

Materials and Construction of Pellet Types

Have you ever wondered what materials make up the pellets you shoot? The construction of pellets depends heavily on their raw materials. Here’s what you need to know:

- Lead is the primary material because of its high density and malleability, which improve accuracy and energy transfer.

- Alternative materials like zinc, copper, and frangible metals are used for eco-friendly pellets, reducing environmental impact.

- Steel BBs are coated with zinc or copper to prevent rust and ensure smooth firing.

- The manufacturing process involves compressing raw materials through molds, with lignin acting as a natural binder during high-temperature pressing.

- The material composition of pellets directly influences their durability, performance, and environmental footprint. Additionally, understanding the material properties helps in selecting the best pellet type for specific shooting needs.

How Pellet Shape and Design Affect Performance

Your choice of pellet shape and design directly impacts how well it performs in flight, affecting stability and accuracy. Aerodynamically shaped pellets, like domed types, stay stable over longer distances, even in windy conditions, while flat-headed wadcutters excel in target scoring. Additionally, pointed and hybrid designs enhance penetration and impact, making them ideal for hunting or specific shooting needs. The design of the pellet can also influence its durability and consistency during use. Moreover, the effectiveness in different environments depends on the pellet’s shape, which can be optimized through understanding aerodynamics, material properties, and how Best Heat Pump techniques improve vehicle performance. Advances in automation technologies are also contributing to more precise manufacturing processes, ensuring higher quality in pellet production. Proper maintenance and installation practices, as highlighted in heat pump care, also underscore the importance of selecting high-quality components for optimal performance.

Aerodynamics and Stability

The shape and design of a pellet play a crucial role in its aerodynamic performance and stability during flight. Your choices directly influence flight accuracy and ballistic stability. Consider these factors:

- Aerodynamic shape: Streamlined designs like domed or hybrid shapes reduce drag coefficient, maintaining higher velocity and stability.

- Flight trajectory: Optimized shapes help pellets resist wind drift, ensuring more consistent hits.

- Stability in flight: Proper shape enhances rotational stability, preventing tumbling or wobbling.

- Shape optimization: Adjustments to the pellet’s skirt and head improve engagement with rifling, further boosting stability and ballistic performance.

Impact and Penetration

Pellet shape and design play a crucial role in determining impact and penetration performance, especially at different ranges and target types. Pointed pellets excel in penetration due to their aerodynamic shape, allowing deeper impact at long range. Hollow points expand upon impact, increasing ballistic damage and transfer of impact energy, making them effective for close to medium-range targets. Wadcutter pellets prioritize accuracy but have limited penetration, while domed pellets maintain velocity and impact force over longer distances. Heavier slugs and hybrid pellets with pointed tips maximize impact energy, boosting penetration ability in hunting scenarios. Additionally, ballistic performance is significantly influenced by pellet shape, affecting overall effectiveness in various shooting conditions. Understanding pellet aerodynamics can further enhance shot accuracy and effectiveness across different applications. Moreover, quality control in manufacturing processes ensures consistency in pellet shape and design, which is essential for reliable performance. Proper quality assurance helps maintain optimal pellet consistency, directly impacting accuracy and overall shooting results.

Factors Influencing Pellet Accuracy and Effectiveness

Your pellet’s material purity and consistency play a key role in its accuracy and reliability. Manufacturing precision and tight tolerances guarantee each pellet performs predictably shot after shot. When these factors are controlled, you’ll notice better consistency and improved overall effectiveness. Additionally, choosing the Best Airless Paint Sprayer ensures efficient and uniform application, which can further enhance your project results. Proper maintenance of your equipment and understanding tanning bed risks can also contribute to safer, more effective outcomes. In the context of tuning, Mazda B2200 Tuning components can benefit from precise materials and manufacturing standards to ensure consistent performance. Utilizing high-quality materials and adhering to HEPA filtration specifications can also greatly enhance air purity and overall effectiveness.

Material Purity and Consistency

Material purity and consistency are essential factors that directly impact pellet performance. You must guarantee high material purity to prevent impurities and contaminants like sawdust or sand, which can cause uneven burning and blockages. During the manufacturing process, maintaining uniform size and density is critical; these factors influence pellet consistency, fit, and shooting accuracy. Keep moisture content below 8% to avoid swelling or disintegration, which compromise pellet integrity. Properly processed raw materials with minimal impurities help preserve structural integrity, ensuring reliable combustion and energy transfer. Additionally, controlling the shedding of pet hair during storage and handling can help maintain pellet cleanliness and quality. Ensuring raw material quality is consistent throughout production is vital for achieving reliable performance and predictable results. Consistent raw material quality aids in minimizing defects and enhances overall pellet reliability. By controlling these elements, you optimize pellet quality, leading to consistent performance and accuracy. Incorporating quality control measures throughout production can further enhance overall pellet reliability. In short, attention to material purity and uniformity directly enhances your pellets’ effectiveness and longevity.

Manufacturing Precision and Tolerances

Achieving ideal accuracy and effectiveness in pellet shooting depends heavily on manufacturing precision, which requires strict control over raw materials, drying, and cleaning processes. Precise manufacturing guarantees consistent size and density, critical for proper fit and ballistic behavior. Tolerances in pellet diameter, usually within ±0.02 mm, directly influence accuracy and reliability. High-quality pellets follow strict production standards, including standardized testing and certification like EN PLUS or DINPLUS, to guarantee uniformity. Variations in compression pressure and temperature during production impact shape, weight, and stability. Maintaining tight manufacturing tolerances minimizes deviations, resulting in improved accuracy and performance.

| Manufacturing Aspect | Impact on Pellet Quality |

|---|---|

| Raw materials | Consistency in size, density |

| Tolerances | Accuracy and fit |

| Production standards | Ballistic behavior consistency |

The Role of Pellet Weight in Shooting Dynamics

Pellet weight plays a crucial role in shaping shooting dynamics, influencing both velocity and stability. Heavier pellets (above 15 grains) deliver greater impact energy and stability over long distances, enhancing accuracy and knockdown power. Lighter pellets (under 15 grains) accelerate faster, resulting in higher velocity and flatter trajectories ideal for short-range shots. Consider these points:

- Matching pellet weight to your airgun improves overall accuracy and consistency.

- Heavier pellets reduce the effects of wind, boosting stability in outdoor shooting.

- Using too heavy a pellet can decrease velocity and damage your gun’s performance.

- Ideal shooting depends on matching pellet weight with your specific firearm and intended shot distance.

- Selecting the appropriate pellet weight also involves understanding the performance characteristics of different pellet types for optimal results. A proper understanding of pellet types can help you make better choices for your shooting needs. Additionally, staying informed about AI security developments can help manufacturers ensure the safety and reliability of shooting equipment technology. Understanding the material composition of pellets can further enhance your selection process by matching pellets to your shooting conditions and goals.

Choosing the right pellet weight ensures better airgun performance and more precise shots, especially when considering trajectory and impact energy.

Choosing High-Quality Pellets for Optimal Results

To guarantee peak performance and safety, selecting high-quality pellets is essential. Look for certification labels like EN PLUS or DINPLUS, which confirm compliance with safety standards and quality specifications. Check packaging for detailed data on calorific power, ash residue, and moisture content—aim for low impurities and consistent size. Conduct water and handling tests at home to assess durability; good pellets shouldn’t disintegrate easily or produce excessive sawdust. Avoid low-priced options lacking certification, as they often compromise combustion efficiency and produce more emissions. Prioritize certified pellets to ensure safety, durability, and superior system performance.

| Certification | Specifications | Durability |

|---|---|---|

| EN PLUS, DINPLUS | Calorific power, ash, moisture | Water and handling tests |

Frequently Asked Questions

What Are the Different Types of Pellets?

You’re curious about the different types of pellets, and there’s a variety to choose from. Diabolo pellets are the most common, known for stability and accuracy. Wadcutter pellets have flat heads perfect for target shooting. Pointed pellets offer better penetration, ideal for hunting small game. Hollow-point pellets expand on impact, providing more damage for close-range hunting. Each type is designed for specific shooting needs, so pick the right one for your purpose.

What Type of Pellet Is Most Accurate?

Did you know that the most accurate pellet varies by shooting distance? For close-range, wadcutter pellets excel due to their flat head design creating clean holes. At longer ranges, domed pellets maintain velocity and stability. Your best bet is testing different types with your gun; well-matched, consistent pellets—regardless of shape—are key to accuracy. Proper fit and quality guarantee you get the most precise shots every time.

Is .177 or .22 Better?

When choosing between .177 and .22, consider what you need. If you want pinpoint accuracy and flatter trajectories for target shooting, go with .177. But if you need more stopping power for hunting or pest control, .22 is your best choice. Both work well when matched to your airgun’s specifications and your purpose, so pick the one that best fits your specific needs.

What Is the Difference Between 4.5 and 5.5 Pellets?

You might think all pellets are the same, but the difference between 4.5mm and 5.5mm pellets is significant. The 4.5mm ones are smaller, ideal for precise target shooting with higher velocity and flatter trajectories. Meanwhile, 5.5mm pellets are larger, delivering more impact energy, making them better for hunting or long-range shooting. Choosing the right size depends on your airgun’s caliber and your specific needs for accuracy or power.

Conclusion

Choosing the right pellet can make or break your shooting game—it’s practically the difference between hitting a dime or missing a moon! High-quality pellets are the secret weapon that transforms your accuracy from good to legendary. Don’t settle for less; your shots deserve the best. With the right pellet, you’ll be unstoppable, dominating targets with precision that feels like magic. Elevate your shooting today and watch your skills reach astronomical heights!