Alright, everyone, I’m here to show you how to spread that cozy, wood stove warmth throughout your lovely home. Say goodbye to cold spots and hello to warm, cozy feet.

In this article, I’ll be sharing some tried-and-true methods to ramp up the warmth in your home. We’ll cover everything from utilizing ceiling fans and heat transfer methods to strategic furniture placement.

So, let’s dive in and make that wood stove work its magic!

Key Takeaways

- Proper insulation and the use of heat powered fans are essential for efficient heat circulation from a wood stove.

- Ceiling fans can complement wood stoves by circulating heat and pushing warm air towards colder areas of the room.

- Radiators and heat exchangers are effective methods for distributing heat from a wood stove, with radiators using convection and heat exchangers transferring heat between fluids.

- Strategic furniture placement, window insulation, and the use of heat reflectors can optimize heat circulation and prevent heat loss from a wood stove.

The Importance of Proper Airflow

Proper airflow is crucial for effectively circulating heat from my wood stove. When it comes to heating your home, insulation plays a significant role in retaining the warmth generated by your wood stove. Insulation acts as a barrier, preventing heat from escaping through the walls, floors, and ceilings. By ensuring that your home is properly insulated, you can maximize the efficiency of your wood stove and reduce energy waste.

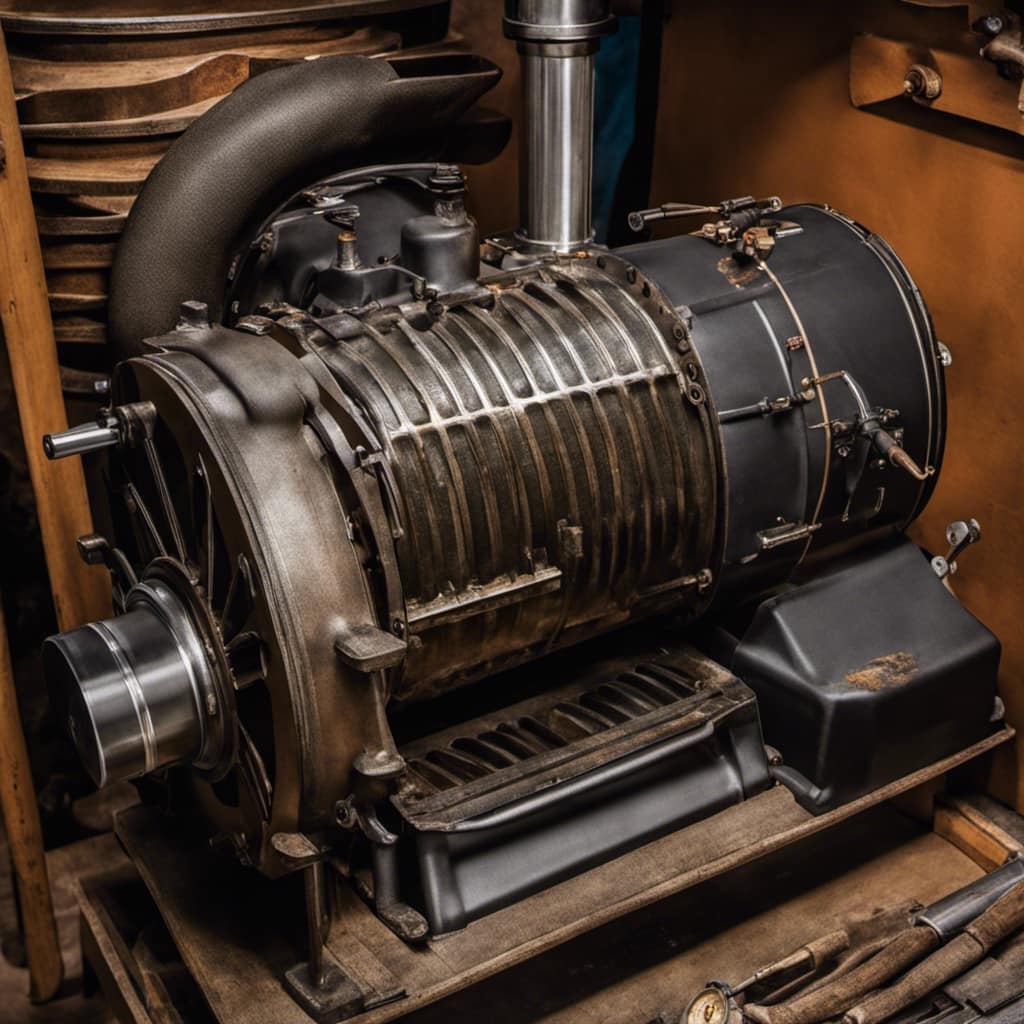

One effective way to enhance heat circulation is by using a heat powered fan. These fans are designed to distribute the heat generated by your wood stove more efficiently throughout the room. They operate by utilizing the heat from the stove to generate electricity, which powers the fan blades. As the fan spins, it pushes the warm air away from the stove and into the surrounding area, ensuring that the heat is effectively distributed throughout the room.

By utilizing a heat powered fan, you can enjoy several benefits. Firstly, it helps to even out the temperature in the room, eliminating cold spots and ensuring that every corner receives warmth. Secondly, it reduces the reliance on convection currents, which can be slow and ineffective in distributing heat evenly. Lastly, it aids in reducing the amount of wood you need to burn, as the fan helps to circulate the heat more efficiently, maximizing its effectiveness.

Transitioning into the subsequent section about utilizing ceiling fans to enhance heat distribution, it’s important to note that while heat powered fans are effective in circulating heat within a room, they mightn’t be sufficient for distributing heat throughout the entire house. This is where ceiling fans can come in handy.

Utilizing Ceiling Fans to Enhance Heat Distribution

I can enhance the distribution of warmth in my home by using ceiling fans. Ceiling fans aren’t just for cooling during the summer; they can also help circulate heat in the winter months. Here are four ways I can optimize the use of ceiling fans to enhance heat distribution:

Fan placement: To effectively circulate heat, I should place my ceiling fans in strategic locations. Placing them near windows or doors can help push warm air towards colder areas of the room.

Fan speed control: Adjusting the fan speed can make a significant difference in heat distribution. Running the fan on a low setting will gently push warm air down without creating a draft, while a higher speed can help distribute heat more quickly.

Reverse the fan direction: Most ceiling fans have a reverse function, which allows the blades to rotate in the opposite direction. By reversing the fan during winter, I can push the warm air that naturally rises towards the ceiling back down into the room.

Use in conjunction with other heating methods: Ceiling fans can complement other heat sources, like wood stoves. By positioning the fan near the stove, I can help circulate the warm air throughout the room more effectively.

By utilizing these tips, I can ensure that the warmth from my wood stove reaches every corner of my home, creating a cozy and comfortable environment.

Now, let’s explore other heat transfer methods, such as radiators and heat exchangers.

Heat Transfer Methods: Radiators and Heat Exchangers

Radiators and heat exchangers are efficient ways to distribute warmth throughout a room. These heat transfer techniques are essential for improving heating efficiency, ensuring that the warmth from your wood stove reaches every corner of your space.

Radiators are commonly used in central heating systems. They work by transferring heat through convection, where warm air rises and cool air sinks. This creates a continuous circulation of warm air, keeping the room evenly heated. Heat exchangers, on the other hand, are devices that transfer heat from one fluid to another. They are often used in combination with a wood stove to capture and distribute the heat more effectively.

To illustrate the benefits of radiators and heat exchangers, here is a comparison table:

| Radiators | Heat Exchangers |

|---|---|

| Use convection to distribute heat | Transfer heat from one fluid to another |

| Effective in central heating systems | Can be used in conjunction with a wood stove |

| Require proper installation and maintenance | Can enhance the heating efficiency of a wood stove |

Maximizing Heat Output With Heat-Resistant Materials

Using heat-resistant materials in my heating system can help maximize the output and ensure that the warmth is effectively distributed throughout my space. When it comes to insulating materials, there are a few key options that can greatly impact the efficiency of my heating system. Here are four reasons why using these materials is essential:

Energy savings: Heat-resistant materials have excellent insulating properties, which means they can help retain heat within the heating system. This results in less energy consumption and lower heating bills.

Improved heat conduction: These materials are designed to conduct heat efficiently, allowing for better transfer of heat from the heating system to the surrounding space. This ensures that the warmth is evenly distributed, eliminating cold spots and maximizing comfort.

Enhanced durability: Heat-resistant materials are specifically designed to withstand high temperatures, preventing any damage or deterioration caused by prolonged exposure to heat. This increases the lifespan of the heating system and reduces the need for frequent repairs or replacements.

Safety assurance: Using heat-resistant materials reduces the risk of fire hazards. These materials are designed to resist combustion and prevent the spread of flames, providing peace of mind and ensuring the safety of my space.

Strategic Furniture Placement for Effective Heat Circulation

Placing furniture strategically throughout the room allows for better airflow and helps distribute the warmth evenly.

When it comes to maximizing heat circulation from a wood stove, there are several factors to consider. One important aspect is window insulation. By ensuring that your windows are properly insulated, you can prevent cold drafts from entering the room and warm air from escaping. This will help maintain a consistent temperature and improve heat circulation.

Another effective technique is using heat reflectors to direct warmth towards desired areas. Heat reflectors are simple devices that can be placed behind the stove to reflect heat back into the room. By positioning these reflectors strategically, you can ensure that the warmth is directed towards areas where it’s most needed, such as seating areas or bedrooms. This can significantly enhance the efficiency of your wood stove and improve overall comfort.

In addition to window insulation and heat reflectors, furniture placement plays a crucial role in heat circulation. You should avoid blocking air vents or radiators with large pieces of furniture, as this can impede the flow of warm air. Instead, try to arrange your furniture in a way that promotes good airflow throughout the room. For example, placing furniture away from walls and creating open spaces allows warm air to circulate freely, ensuring that every corner of the room receives adequate heat.

Is Circulating Hot Air from a Wood Stove the Same as Circulating Heat?

Yes, circulating hot air from a wood stove is the same as circulating heat. A wood stove’s fan helps to distribute the heat throughout the room, making the space warm and cozy. When the circulating hot air wood stove is running, you can feel the warmth in every corner.

Frequently Asked Questions

Can I Use a Wood Stove Without Proper Airflow?

Using a wood stove without proper airflow can significantly affect its efficiency. Adequate airflow is essential for the combustion process, allowing the wood to burn efficiently and produce more heat. Without proper airflow, the fire may smolder and create more smoke, resulting in less heat being produced.

Additionally, a lack of airflow can lead to the build-up of creosote and other harmful byproducts, which can pose a safety risk. Therefore, ensuring proper airflow is crucial for maximizing the heat output of your wood stove.

How Can I Enhance Heat Distribution in My Home Without Using Ceiling Fans?

Enhancing heat distribution in my home without using ceiling fans can be achieved through various non-fan heat circulation methods.

One effective way is by utilizing a heat-powered stove fan, which uses the heat from the wood stove to generate its own power and circulate the warm air throughout the room.

Additionally, strategically placing thermal curtains or installing a heat transfer kit can help redirect and distribute the heat more efficiently.

These methods can significantly improve heat distribution and create a cozy and comfortable environment.

What Are Some Alternative Heat Transfer Methods to Radiators and Heat Exchangers?

Well, there are a few alternative methods to consider when it comes to heat distribution in your home.

One option is thermal curtains, which can help trap heat and prevent it from escaping through windows.

Another option is underfloor heating, which uses pipes or electric mats installed beneath the floor to radiate heat upwards.

These methods can be effective in circulating heat without relying on radiators or heat exchangers.

Are There Any Other Ways to Maximize Heat Output Besides Using Heat-Resistant Materials?

There are several alternative methods to maximize heat output besides using heat-resistant materials.

One effective way is to improve heat circulation. This can be achieved by installing a fan or blower near the wood stove to help distribute warm air throughout the room.

Another option is to use a duct system that connects the wood stove to different areas of the house, allowing heat to be transported to multiple rooms.

Both of these methods can greatly enhance the efficiency of a wood stove’s heat output.

Is Strategic Furniture Placement the Only Way to Effectively Circulate Heat in a Room?

Strategic furniture placement isn’t the only way to effectively circulate heat in a room. Heat transfer through windows can also play a significant role in distributing heat.

By keeping curtains open during the day, sunlight can enter the room and warm it up. At night, closing the curtains can help to insulate the room and prevent heat from escaping through the windows.

This simple method can enhance the overall heat distribution in a space.

Conclusion

In conclusion, proper heat circulation is crucial for maximizing the efficiency of a wood stove. By utilizing ceiling fans, heat transfer methods like radiators and heat exchangers, and strategic furniture placement, you can ensure that the warmth from your wood stove reaches every corner of your space.

Some may argue that these methods require additional time and effort, but the long-term benefits of a cozy and evenly heated home make it well worth it.

Growing up surrounded by the vast beauty of nature, Sierra was always drawn to the call of the wild. While others sought the comfort of the familiar, she ventured out, embracing the unpredictable and finding stories in the heartbeat of nature.

At the epicenter of every remarkable venture lies a dynamic team—a fusion of diverse talents, visions, and passions. The essence of Best Small Wood Stoves is crafted and refined by such a trio: Sierra, Logan, and Terra. Their collective expertise has transformed the platform into a leading authority on small wood stoves, radiating warmth and knowledge in equal measure.