Exploring the intricate inner workings of a wood stove catalytic converter, I am amazed by its capability to convert harmful emissions into less toxic compounds.

This remarkable device utilizes a chemical reaction to convert carbon monoxide and other pollutants into water vapor and carbon dioxide.

By understanding the key components and factors that impact its efficiency, we can appreciate the benefits it brings to our environment.

Let us unravel the mysteries behind the functioning of a wood stove catalytic converter.

Key Takeaways

- Wood stove catalytic converters reduce harmful emissions by converting carbon monoxide, nitrogen oxides, and volatile organic compounds into carbon dioxide, nitrogen, and water vapor.

- The catalytic converter utilizes a catalyst, typically made of platinum, palladium, or rhodium, which promotes specific reduction reactions and facilitates the transfer of electrons.

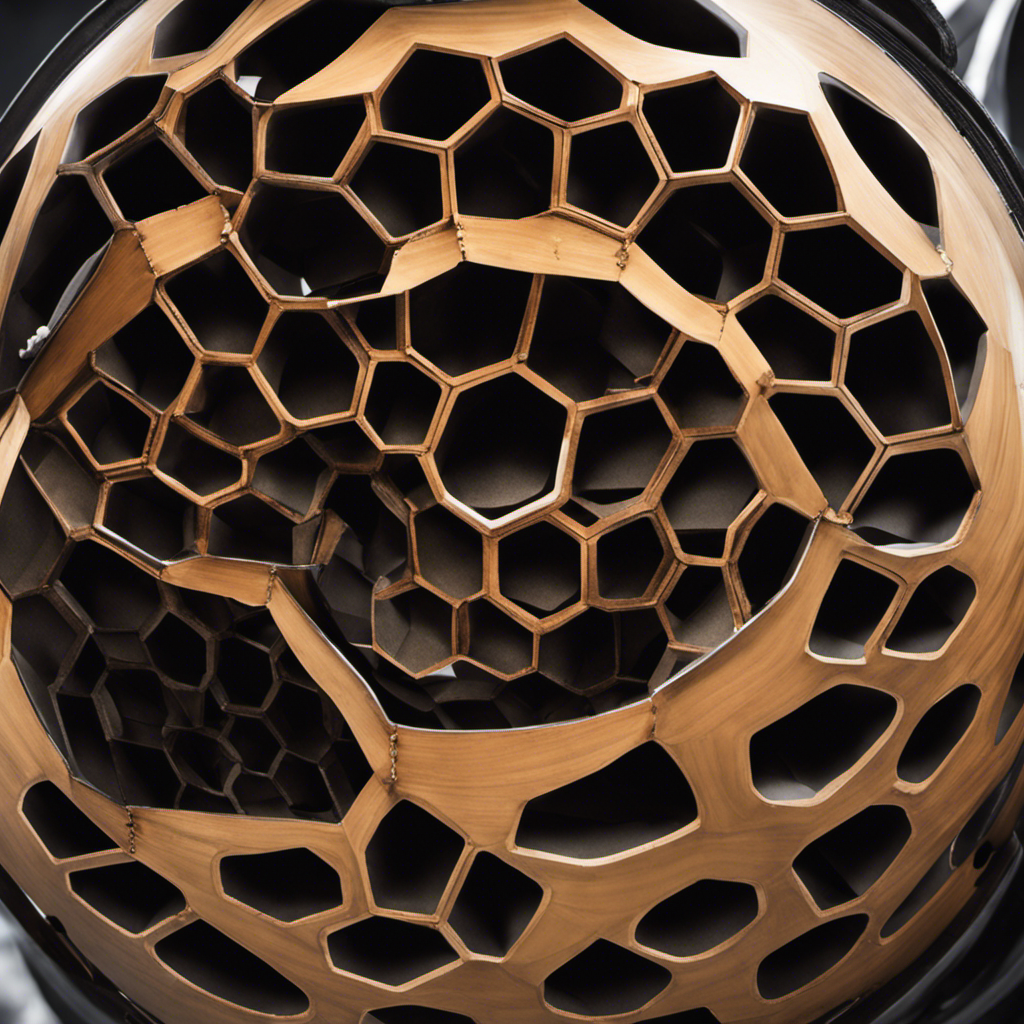

- The converter consists of a ceramic honeycomb substrate that provides a high surface area and a housing made of stainless steel.

- The efficiency of the converter is dependent on proper airflow and temperature control, with restricted airflow or low temperature reducing efficiency and increasing emissions, while high airflow or high temperature can damage the converter. Regular maintenance and adjustment are necessary for optimal performance.

The Purpose of a Wood Stove Catalytic Converter

I think the purpose of a wood stove catalytic converter is to reduce harmful emissions.

The science behind catalytic conversion involves using a catalyst to facilitate a chemical reaction that transforms harmful pollutants into less harmful substances.

In the case of wood stove catalytic converters, the catalyst typically consists of a ceramic or metal honeycomb structure coated with precious metals such as platinum, palladium, and rhodium.

These metals act as catalysts by providing a surface for the pollutants to react with oxygen and undergo oxidation or reduction reactions.

The role of catalysts in wood stove catalytic converters is to promote the conversion of carbon monoxide (CO), nitrogen oxides (NOx), and volatile organic compounds (VOCs) into carbon dioxide (CO2), nitrogen (N2), and water vapor (H2O).

This conversion process helps to significantly reduce the harmful emissions from wood stoves, making them more environmentally friendly.

Understanding the Chemical Reactions in a Catalytic Converter

To truly comprehend the chemical reactions in a catalytic converter, one must carefully study the intricate role of the catalyst in facilitating the transformation of harmful pollutants into less harmful substances.

Chemical catalysts play a crucial role in reducing these harmful emissions by promoting specific reduction reactions. The catalyst, typically made of platinum, palladium, or rhodium, provides a surface for the reactants to interact and undergo chemical transformations.

In reduction reactions, the catalyst facilitates the transfer of electrons, leading to the conversion of pollutants such as nitrogen oxides (NOx), carbon monoxide (CO), and unburned hydrocarbons (HC) into nitrogen (N2), carbon dioxide (CO2), and water vapor (H2O). This process occurs through a series of intermediate steps, where the catalyst promotes the breaking and formation of chemical bonds.

Understanding these chemical reactions is crucial for developing efficient catalytic converters that can effectively reduce harmful emissions and mitigate their impact on the environment.

The Key Components of a Wood Stove Catalytic Converter

Although a wood stove catalytic converter contains various components, the key ones are the catalyst, the ceramic honeycomb substrate, and the housing.

The catalyst is typically made of platinum, palladium, or rhodium, and it facilitates the chemical reactions that convert harmful pollutants into less harmful substances.

The ceramic honeycomb substrate provides a high surface area for the catalyst to interact with the exhaust gases.

The housing, usually made of stainless steel, ensures that the converter is sealed and properly mounted to the wood stove.

The function of a wood stove catalytic converter is to improve the combustion efficiency and reduce emissions by promoting the oxidation of carbon monoxide and the reduction of nitrogen oxides.

This process occurs through the combination of heat transfer and catalytic reactions, resulting in a cleaner and more efficient wood stove operation.

How Airflow and Temperature Control Impact Converter Efficiency

The airflow and temperature control are crucial factors that directly impact the efficiency of the wood stove catalytic converter. Proper maintenance of these components is essential to ensure optimal performance.

When the stove is operating, the airflow delivers the smoke and gases to the converter where the chemical reactions take place. The temperature control plays a vital role in maintaining the optimal temperature range for these reactions to occur.

If the airflow is restricted or the temperature is too low, the converter may not function effectively, leading to reduced efficiency and increased emissions. On the other hand, if the airflow is too high or the temperature is too high, it can damage the converter and decrease its lifespan.

Therefore, regular maintenance and careful adjustment of airflow and temperature are necessary to maximize the efficiency of the wood stove catalytic converter.

Transition: Now that we understand the impact of airflow and temperature control on the converter’s efficiency, let’s explore the benefits and limitations of wood stove catalytic converters.

Benefits and Limitations of Wood Stove Catalytic Converters

One benefit of wood stove catalytic converters is their ability to reduce harmful emissions, but their limitations include the need for regular maintenance and careful adjustment.

Advantages of wood stove catalytic converters:

- Reduction of harmful emissions: Catalytic converters help in reducing the emission of pollutants such as carbon monoxide, nitrogen oxides, and particulate matter, making wood stoves more environmentally friendly.

- Increased efficiency: These converters improve the efficiency of wood stoves by promoting complete combustion, resulting in better heat output and reduced fuel consumption.

- Improved indoor air quality: By reducing emissions, wood stove catalytic converters help in maintaining better indoor air quality, reducing the risk of respiratory issues and allergies.

- Compliance with regulations: Wood stove catalytic converters help wood stove owners comply with environmental regulations and emission standards, ensuring a cleaner and safer environment.

Drawbacks of wood stove catalytic converters:

- Maintenance requirements: Catalytic converters require regular maintenance, including cleaning and replacement, to ensure optimal performance.

- Sensitivity to fuel quality: These converters may be sensitive to the quality of fuel used, and low-quality or wet wood can negatively impact their efficiency.

- Initial cost: Wood stove catalytic converters can be expensive to purchase and install, adding to the overall cost of owning a wood stove.

- Adjustment complexities: Proper adjustment of catalytic converters is crucial for their effective operation, requiring technical expertise and careful monitoring.

Frequently Asked Questions

Can a Wood Stove Catalytic Converter Be Installed in Any Type of Wood Stove?

Yes, a wood stove catalytic converter can be installed in most types of wood stoves. However, there are specific installation requirements to ensure proper functioning. The benefits include increased efficiency and reduced emissions, but drawbacks may include higher cost and maintenance.

How Often Should a Wood Stove Catalytic Converter Be Cleaned or Replaced?

I clean my wood stove catalytic converter every six months and replace it every three years. Regular cleaning ensures optimal performance and reduces emissions, while replacement is necessary to maintain efficiency and prevent damage.

Are There Any Safety Concerns or Risks Associated With Using a Wood Stove Catalytic Converter?

There are safety concerns and risks associated with using a wood stove catalytic converter. It is important to follow proper maintenance tips to ensure optimal performance and reduce the risk of fire or carbon monoxide poisoning.

Can a Wood Stove Catalytic Converter Help Reduce the Emission of Other Pollutants Besides Carbon Monoxide?

Yes, a wood stove catalytic converter can help reduce the emission of other pollutants besides carbon monoxide. It has been proven to be effective in reducing particulate matter and other harmful gases, providing benefits for air quality and human health.

Are There Any Specific Maintenance Tips or Recommendations for Ensuring the Optimal Performance of a Wood Stove Catalytic Converter?

Maintenance tips for optimal performance of a wood stove catalytic converter include regular cleaning and inspection. The cleaning frequency depends on usage and can vary, but it is crucial to prevent build-up and ensure efficient operation.

Conclusion

In conclusion, wood stove catalytic converters are an essential component in reducing emissions and improving the efficiency of wood-burning stoves. By harnessing chemical reactions and controlling airflow and temperature, these converters help minimize environmental impact.

While they’ve their limitations, such as the need for regular maintenance and higher initial cost, their benefits can’t be overstated. They’re a vital tool in creating a more sustainable and eco-friendly heating solution for our homes.