Based on my latest research, the top three hydronic coil heat exchangers of 2025 in the 18×20 size are the 18×20 Water to Air Heat Exchanger for outdoor wood furnaces, the VEVOR Water-to-Air Heat Exchanger featuring copper ports and aluminum fins, and the HTL18X20 model with copper brazed edges. These units offer high efficiency, durable construction, and versatile installation options. Keep exploring to discover which one best fits your heating needs and system compatibility.

Key Takeaways

- Top-rated models support 18×20-inch size with high thermal efficiency and durable copper and steel construction.

- Features include multiple connection ports, versatile mounting options, and compatibility with standard HVAC piping.

- Designed for reliable performance across a wide temperature range (-40°F to 356°F) in residential and commercial systems.

- Considerations include weight, installation space, and ensuring system compatibility for optimal operation.

- Reviews highlight value, warranty options, and ease of integration for professional or DIY HVAC applications.

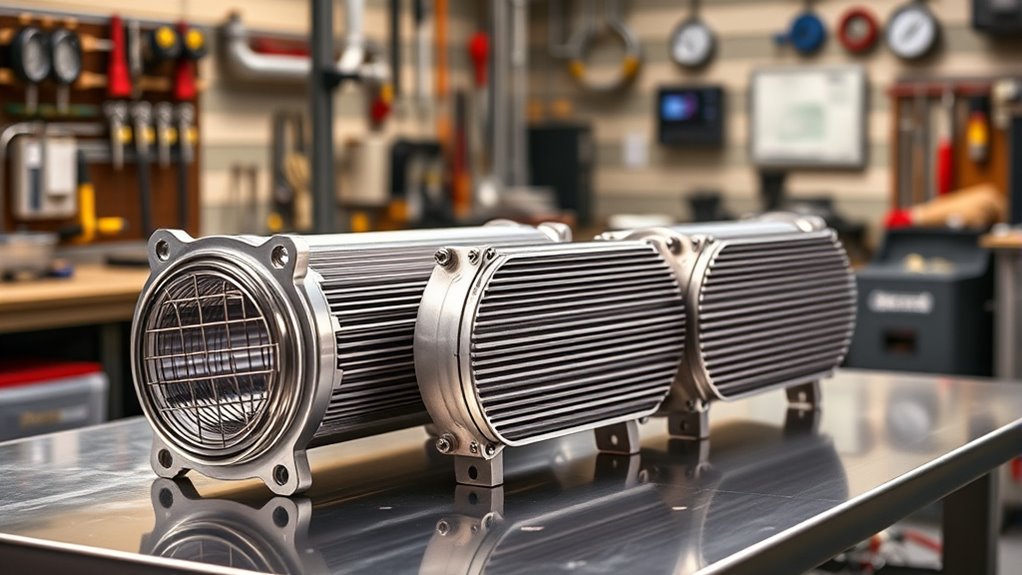

18×20 Water to Air Heat Exchanger for Outdoor Wood Furnaces

If you’re looking for a reliable and efficient solution to heat large outdoor spaces, the 18×20 Water-to-Air Heat Exchanger is an excellent choice. I’ve used it in outdoor wood furnace setups, and its high thermal efficiency really stands out. Made from durable 306 steel with aluminum fins and copper tubes, it handles high temperatures and pressures well. It’s lightweight, easy to install, and integrates seamlessly with existing systems for heating, cooling, or dehumidification. Whether for residential or commercial use, this exchanger provides consistent, efficient heat transfer without needing electricity, making it perfect for DIY projects or professional installations.

Best For: homeowners and professionals seeking an efficient, durable heat exchanger for outdoor wood furnace setups, large-scale heating, or DIY climate control projects.

Pros:

- High thermal efficiency with direct heat transfer without electricity or oxygen consumption

- Durable construction with 306 steel case, aluminum fins, and copper tubes resistant to high pressures and temperatures

- Lightweight and easy to install, suitable for various outdoor heating and cooling applications

Cons:

- Fins and packaging may be susceptible to minor damage during shipping

- Requires proper installation and system integration for optimal performance

- Limited information on detailed warranty and customer support options

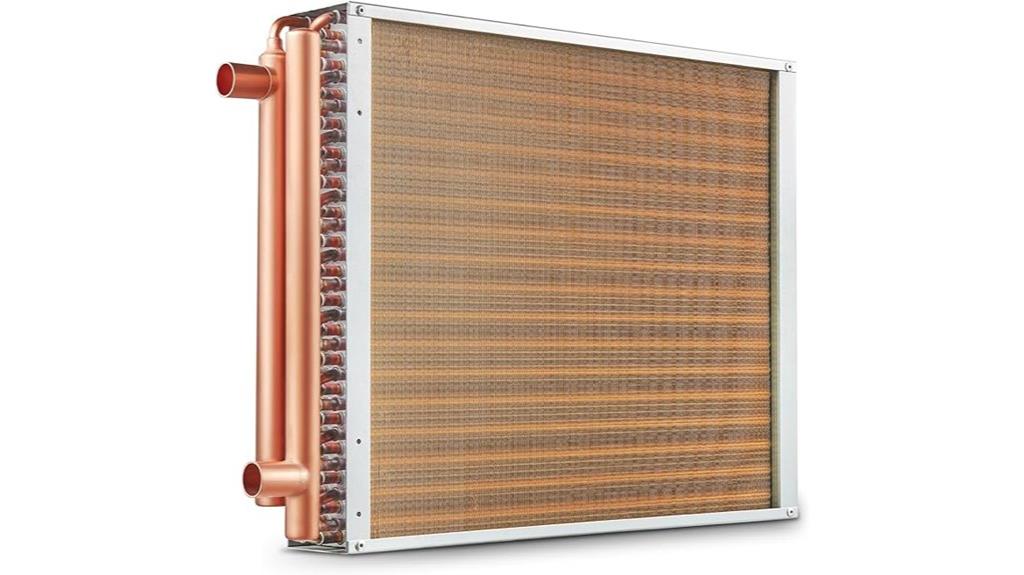

VEVOR Water-to-Air Heat Exchanger, 18×20, Copper Ports & Aluminum Fins

The VEVOR Water-to-Air Heat Exchanger stands out as an excellent choice for those seeking reliable outdoor heating or cooling solutions, thanks to its robust construction and high thermal efficiency. Measuring 18×20 inches, it features three rows of 3/8 copper ports and 242 aluminum fins, supporting temperatures from -40℉ to 356℉. Its copper brazed edges ensure durability and leak resistance, while epoxy-coated fins resist corrosion and wear. Capable of delivering up to 160,000 BTU/hr, this unit offers excellent heat transfer thanks to its large surface area, multiple fins, and seamless copper tubes. It’s designed for longevity and reliable performance in residential and outdoor HVAC systems.

Best For: homeowners and HVAC professionals seeking a durable, high-efficiency water-to-air heat exchanger for outdoor heating, cooling, or forced air systems.

Pros:

- High thermal transfer efficiency with large surface area and multiple fins

- Durable construction with copper brazing and epoxy-coated aluminum fins for corrosion and leak resistance

- Supports wide temperature range (-40°F to 356°F) and delivers up to 160,000 BTU/hr

Cons:

- Relatively heavy at 17.6 pounds, may require sturdy mounting support

- Limited to 110V power supply, which may not suit all installation environments

- No included warranty or batteries, potentially increasing maintenance costs

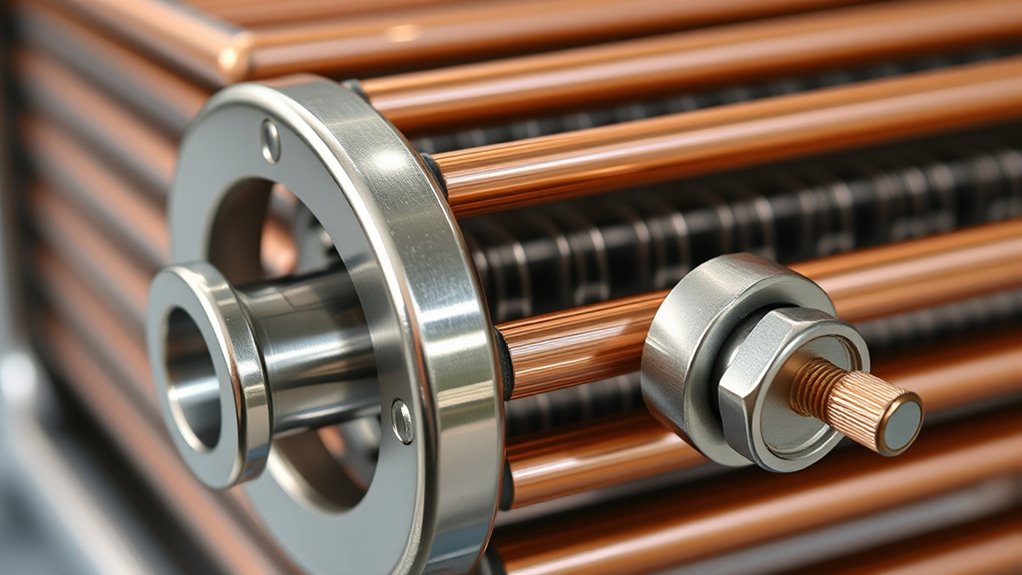

Water to Air Heat Exchanger (HTL18X20) with Copper Ports

Designed for those seeking high efficiency and durability, the Water to Air Heat Exchanger (HTL18X20) with Copper Ports stands out as an ideal choice for residential and commercial heating or cooling systems. It boasts a 140,000 Btu capacity, with the ability to reach 360,000 Btu per hour depending on the application. Constructed with steel shells, epoxy-coated fins, and contact-enhanced copper tubes, it offers excellent heat transfer and resistance to wear. Its flexible installation options and compatibility with renewable sources make it versatile for various setups. Overall, this heat exchanger provides reliable performance, energy efficiency, and long-lasting durability.

Best For: homeowners and HVAC professionals seeking a durable, high-capacity water-to-air heat exchanger for efficient heating and cooling systems in residential or commercial settings.

Pros:

- High thermal capacity up to 360,000 Btu per hour for versatile application needs

- Constructed with durable steel shells and corrosion-resistant copper and aluminum fins for long-lasting performance

- Flexible installation options including clamps, welding, or adapters to suit various setup requirements

Cons:

- May require professional installation due to multiple connection options and technical requirements

- Heavier than smaller or less robust units, potentially impacting installation logistics

- Higher initial cost compared to basic heat exchanger models with lower capacity

Factors to Consider When Choosing Hydronic Coil Heat Exchangers 18X20

When selecting a hydronic coil heat exchanger 18X20, I focus on material durability and resistance to guarantee long-term performance. I also consider heat transfer efficiency and compatibility with existing systems to maximize effectiveness. Finally, I look at installation ease, size, and space requirements to ensure a smooth fit and operation.

Material Durability and Resistance

Material durability and resistance are essential factors to contemplate when selecting a 18×20 hydronic coil heat exchanger because these components must withstand high temperatures, pressures, and harsh environmental conditions without failing. High-quality materials like seamless copper tubes and steel shells ensure the brazed contact points remain leak-proof under demanding conditions. Resistance to corrosion is equally important, often achieved through coatings or using corrosion-resistant metals, which extend the unit’s lifespan. Epoxy-coated fins and protective finishes prevent internal scaling and corrosion, maintaining efficient heat transfer over time. Additionally, the materials chosen must resist environmental factors such as humidity, water vapor, and chemical exposure, ensuring the heat exchanger’s long-term operational integrity. Overall, durable materials are vital for reliable, safe, and efficient performance.

Heat Transfer Efficiency

Maximizing heat transfer efficiency in an 18×20 hydronic coil hinges on several key factors that influence how effectively heat moves between the fluid and surrounding environment. The surface area plays a crucial role—larger surfaces enable more heat exchange. Fin density, such as more aluminum fins per inch, increases conductive contact and improves transfer rates. Material conductivity is also vital; copper’s high thermal conductivity outperforms less conductive options, boosting efficiency. The number of copper tube rows and their seamless construction enhance fluid contact and heat exchange. Proper brazing at contact points ensures minimal leaks and maintains high thermal conductivity. By considering these factors, you can select a hydronic coil that delivers ideal heat transfer performance for your system’s needs.

Compatibility With Systems

Choosing a hydronic coil heat exchanger that fits seamlessly into your existing system requires careful attention to compatibility factors. First, check that the connection ports match your system’s piping size and type, like 3/8-inch copper ports, for easy integration. Next, ensure the exchanger’s dimensions, such as 18×20 inches, fit within your available space without issues. Compatibility with operating temperature ranges is also essential; confirm the exchanger can handle temperatures from -40℉ to 356℉ to prevent thermal stress. Additionally, verify that the pressure ratings align with your system’s pressure levels for safety and reliability. Finally, consider the materials used—copper and aluminum fins should be compatible with your system’s fluid type and corrosion resistance needs, guaranteeing long-term performance.

Installation Ease and Flexibility

Since ease of installation can substantially impact your project timeline, it’s important to select a hydronic coil heat exchanger that offers flexible mounting options and straightforward connections. Look for models with multiple connection ports, such as four thickened MNPT ports, which make attaching pipes simple without needing adapters. Opt for units that support vertical or horizontal mounting to fit various space constraints easily. Easy integration with existing piping systems is essential, so choose heat exchangers with compatible fittings and simple connection methods. A lightweight, compact design can also reduce handling time and ease installation in tight or complex spaces. Additionally, ensure the unit’s construction, including brazed joints and durable materials, allows for reliable outdoor or high-temperature use without extensive modifications.

Size and Space Requirements

The size and space requirements of a 18×20 hydronic coil heat exchanger are critical factors that can influence your installation process. Since the unit measures roughly 18 inches by 20 inches, you’ll need to ensure sufficient space for proper placement. Adequate clearance around the unit is essential for airflow, maintenance, and secure connections, especially in tight or confined areas. The physical dimensions also determine if the heat exchanger fits within existing ductwork, plenums, or outdoor enclosures without modifications. Larger units tend to offer higher heat transfer capacity but demand more space, impacting your placement options. To avoid issues, I recommend precisely measuring your available installation area beforehand, ensuring the unit’s size aligns with your space and avoiding obstructions or fitting problems.

Operating Temperature Range

Understanding the operating temperature range of a 18×20 hydronic coil heat exchanger is essential to guaranteeing it performs reliably within your system. This range indicates the temperatures at which the unit can operate effectively without risking damage or reduced efficiency. Most models handle temperatures from -40°F to 356°F (-40°C to 180°C), covering a wide variety of applications. Exceeding the upper limit can cause material fatigue or damage, while going below the lower limit may impair heat transfer efficiency. It’s vital to select a heat exchanger whose temperature range aligns with your system’s thermal conditions. Proper matching guarantees peak performance, longevity, and safety, preventing costly failures or operational issues down the line. Always verify these limits before installation to confirm compatibility.

Price and Warranty Options

When choosing a 18×20 hydronic coil heat exchanger, evaluating price and warranty options is essential to making a smart investment. I recommend comparing the cost per BTU to ensure you’re getting good value for your money. Be cautious with budget models, as they may sacrifice durability or features; balance initial costs with long-term reliability. Warranty options vary widely—some offer only a 30-day voluntary return, while others include extended coverage. It’s important to carefully review warranty details, such as parts replacement and service support, to ensure thorough protection against defects or failures. Extended warranties or service agreements can provide extra peace of mind, especially for critical heating applications. Always verify the warranty terms to find the best coverage suited to your needs.

Frequently Asked Questions

What Is the Ideal Material for Longevity in Hydronic Coil Heat Exchangers?

I believe stainless steel is the ideal material for longevity in hydronic coil heat exchangers. It’s highly resistant to corrosion, which helps prevent leaks and deterioration over time. Plus, stainless steel handles high temperatures and pressures well, ensuring consistent performance. I’ve found that investing in stainless steel coils can markedly extend the lifespan of your heat exchanger, saving you money and maintenance hassles in the long run.

How Do I Calculate the Correct Size for My Specific Application?

To find the right size for your application, I start by evaluating my space and heating needs. I measure the area, determine the required heat output, and consult manufacturer specifications. I also consider flow rates and temperature differentials. Then, I use sizing charts or formulas to match my calculations with the exchanger’s capacity, ensuring efficient performance without over- or under-sizing.

What Maintenance Is Required for Optimal Performance?

For ideal performance, I recommend regular inspections of your hydronic coil for signs of corrosion or leaks. I clean the coils periodically to prevent buildup, and I check the connections and valves to make sure they’re tight and functioning properly. Also, I monitor the system’s pressure and temperature, making adjustments as needed. Routine maintenance like these keeps my heat exchanger running efficiently and extends its lifespan.

How Do I Identify a Leak in a Water-To-Air Heat Exchanger?

Imagine your heat exchanger as a delicate pipe maze; a leak is like a tiny crack letting secrets slip out. To spot it, I listen for hissing sounds or pool formations around the unit. I also check for unexplained drops in pressure or water levels. Using a soapy solution on joints can reveal bubbles, indicating leaks. Trust your senses—sometimes, a quick inspection saves a costly repair!

Are There Compatible Accessories or Upgrades for These Heat Exchangers?

Yes, there are compatible accessories and upgrades for these heat exchangers. I recommend adding temperature controllers, flow meters, or bypass valves to optimize performance. Upgrading to corrosion-resistant coatings or adding insulation can extend lifespan. Always check manufacturer compatibility before purchasing accessories to guarantee proper fit and function. These upgrades can improve efficiency, ease maintenance, and adapt the system to specific needs, making your heat exchanger more effective and durable.

Conclusion

After reviewing these top hydronic coil heat exchangers, I believe the theory that copper’s superior heat transfer makes it the best choice holds true. Copper’s durability and efficiency really do set it apart. If you’re looking for reliable performance in an 18×20 size, these models prove that investing in quality materials pays off. Trust me, choosing the right heat exchanger can make a noticeable difference in your heating system’s efficiency and longevity.