Recent advances in baffle and insulation technology offer you smarter, more efficient thermal management solutions. Modern baffles now use innovative materials and designs that optimize airflow, reduce turbulence, and improve heat transfer without increasing energy use. Installation methods have become easier and more flexible, allowing quick upgrades and adjustments. These improvements help you achieve better energy savings, safety, and environmental compliance. Keep exploring to discover how these innovations can directly benefit your systems.

Key Takeaways

- Modern baffles incorporate smarter materials and geometries to optimize airflow and heat transfer efficiency.

- New modular and adjustable designs facilitate easier installation, customization, and on-site tuning.

- Enhanced insulation materials significantly reduce heat loss and improve energy conservation.

- Innovative baffle systems support adaptive thermal management, accommodating system upgrades and process changes.

- These advancements promote sustainability, cost savings, and improved operational safety across industries.

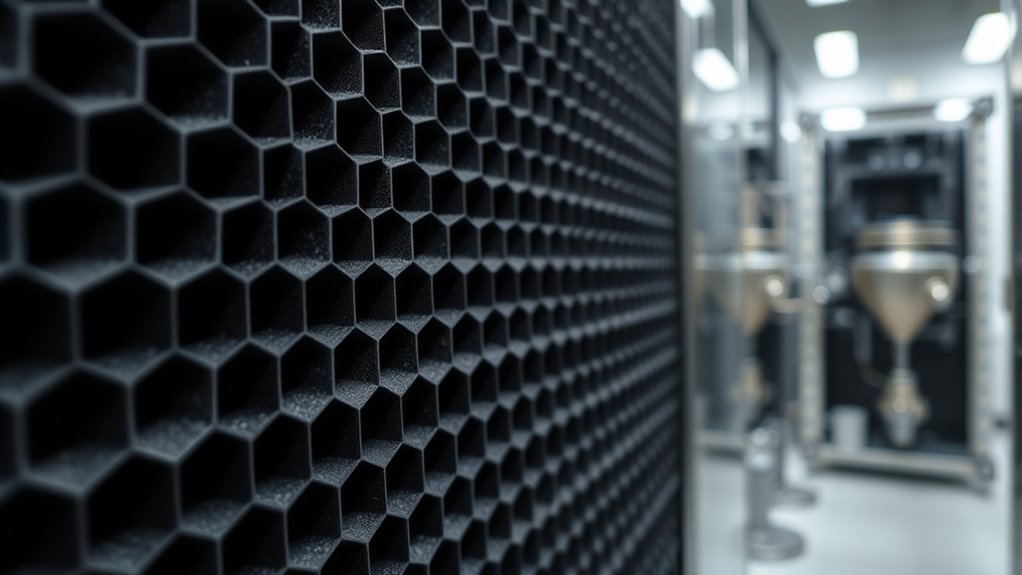

Recent innovations in baffle and insulation technology are transforming how industries manage heat and airflow. As you explore these advancements, you’ll notice significant improvements in thermal performance, which directly impact energy efficiency and operational costs. Modern baffles are now designed with smarter materials and geometries that optimize airflow paths, reduce turbulence, and enhance heat transfer control. These innovations mean that you can achieve better temperature regulation in your systems without increasing energy consumption or relying on bulky, outdated solutions. Whether you’re working in HVAC, industrial processing, or environmental control, upgrading to these new baffle systems can provide substantial gains in thermal performance.

One of the key areas of progress lies in the development of new installation methods. Traditional installation often involved rigid, labor-intensive procedures that limited flexibility and increased downtime. Today, manufacturers have introduced modular baffle designs and versatile mounting options that simplify the setup process. These new installation methods allow you to reduce installation time and minimize disruptions to your operations. You can now easily adapt baffles to various system configurations, whether you’re dealing with complex ductwork or large-scale industrial setups. The ability to quickly and securely install these components not only cuts costs but also enhances overall system reliability.

Furthermore, these advanced installation techniques promote better integration with existing infrastructure. For instance, some baffles now feature adjustable or customizable components, enabling you to fine-tune airflow and thermal management on-site. This adaptability helps you respond swiftly to changing process requirements or system upgrades. Plus, manufacturers are increasingly emphasizing user-friendly installation procedures, often providing detailed guides and training, so your team can implement these solutions confidently and correctly. This focus on ease of installation ensures that you gain the benefits of improved thermal performance without extensive downtime or costly modifications.

In addition to ease of installation, these technological advances are contributing to more sustainable practices. Improved insulation materials reduce heat loss and save energy, while innovative baffle designs help maintain consistent temperature zones. As you adopt these new systems, you’re not just optimizing performance; you’re also supporting environmental sustainability goals. The combination of better thermal performance and streamlined installation methods empowers you to create safer, more efficient, and environmentally friendly operations. Embracing these innovations not only enhances system efficiency but also aligns with broader energy-saving initiatives, helping your facility meet future sustainability standards. As you explore these innovations, you’ll find that they open doors to new possibilities in heat and airflow management, giving you a competitive edge and peace of mind in your facility’s performance.

Frequently Asked Questions

How Do Baffle and Insulation Materials Impact Indoor Air Quality?

Baffle and insulation materials improve indoor air quality by enhancing air circulation and controlling odors. When you use the right baffles, they direct airflow efficiently, reducing stagnant spots where pollutants can accumulate. Insulation helps maintain proper temperature and humidity levels, which prevents mold growth and odors. Together, they create a healthier environment, allowing fresh air to circulate better and keeping unpleasant smells at bay, making your indoor space more comfortable.

What Are the Latest Eco-Friendly Insulation Options Available?

You might be surprised to discover that eco-friendly insulation options are more diverse than ever. Recycled materials like denim, cellulose, and PET bottles are gaining popularity, offering effective insulation while reducing waste. Biodegradable options, such as sheep’s wool and cotton, break down naturally without harming the environment. These choices not only improve your home’s energy efficiency but also help protect the planet, making your space greener and healthier.

How Do Cost Savings Compare Between Advanced and Traditional Insulation?

You’ll find that advanced insulation options often lead to higher upfront costs but save you money long-term through better energy efficiency. Conducting a cost analysis shows that durable materials reduce replacement expenses, making them more economical over time. While traditional insulation might be cheaper initially, its lower material durability can lead to more frequent repairs or replacements, ultimately increasing your costs. Investing in advanced insulation pays off through energy savings and longevity.

Can New Baffle Designs Improve Soundproofing Effectiveness?

Imagine a quiet room where noise seems to vanish like mist—new baffle designs can definitely improve soundproofing. By optimizing baffle shape, you create a more effective barrier that redirects and absorbs sound waves better, enhancing noise reduction. These innovative shapes reduce echo and sound transmission, transforming noisy spaces into tranquil retreats. So, yes, modern baffle designs can markedly boost soundproofing, making your environment calmer and more comfortable.

What Are the Maintenance Requirements for Innovative Insulation Systems?

You should follow the installation guidelines carefully to guarantee your innovative insulation system performs well. Regularly inspect for signs of wear or damage, and clean surfaces as recommended. Conduct durability assessments periodically to confirm the insulation maintains its effectiveness over time. Proper maintenance involves checking seals, replacing damaged sections, and keeping the area dry. Staying proactive helps extend the lifespan of your insulation and maintains ideal soundproofing and energy efficiency.

Conclusion

As you explore these cutting-edge baffle and insulation innovations, imagine the unseen barriers you could harness—silent protectors whispering secrets of efficiency and comfort. With each breakthrough, the future of building design becomes more mysterious and promising. You stand at the edge of a new era, where these advancements could transform spaces in ways you’ve only begun to imagine. Stay tuned; the best is yet to come, and what’s next might just redefine what you thought was possible.